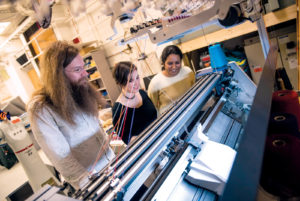

What if you could use a knitting machine much like a 3-D printer to produce a sweater for a customer tailored to fit her perfectly? Not only that, what if she could choose the color and pattern as well? That’s the idea behind technology developed by computer scientists at Carnegie Mellon University, who have developed software for computer-controlled knitting machines that translates 3-D shapes into stitch-by-stitch instructions.

With this system, existing knitting machines used for large-scale production could be used to create customized pieces on demand. Knitters could use it for small-batch production or to create one-of-a-kind garments and accessories.

While this type of technology is used in the 3-D printing world, it hasn’t made the translation to the knitting industry yet. 3-D printers use common languages and file formats to run their equipment, but commercial knitting machines still use a variety of languages and tools that are specific to particular brands. The Carnegie Mellon team is working to change that.

The team developed a method for transforming 3-D meshes, often used for modeling 3-D shapes, into instructions for common V-bed knitting machines. The software uses an algorithm that produces instructions for patterns that work within the limits of the machine, reducing the risk of yarn breaks or jams.

So far, the research team has produced garments and knitted toys in the lab. Currently, they are producing smooth knitted cloth and are working to expand into patterned stitching. For more information,

visit www.cmu.edu.

TEXTILES.ORG

TEXTILES.ORG