The Wilson College of Textiles at North Carolina State University (NC State) is known for turning out textile professionals. Now it’s also turning out socks made by students—and a robot.

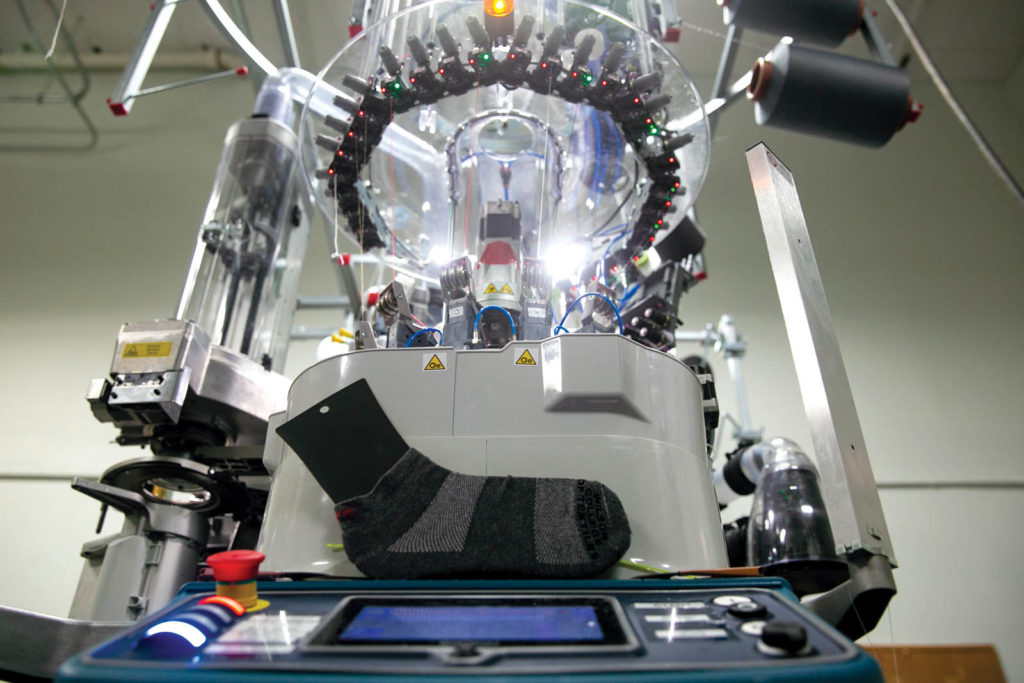

The socks are manufactured with the Zeis Textiles Extension’s (ZTE) sock robot, which arrived on campus earlier this year. ZTE director Andre West was inspired to acquire the machine after attending a five-week course on circular knitting equipment in China in 2019.

“We came back with the idea of, ‘How do we start getting involved in this sort of equipment?’” West says. “The sock machine is an easy start.”

Using this automated circular knitting technology, the machine transforms yarn into a pair of customizable socks in about five minutes. Yarn is fed in and knitted together with a ring of latch hook needles to create an open tube. The tube moves over to a different set of latch hook needles, which rotate to create the heel of the sock. The sock is vacuumed into a tube, where it is stretched around a rod and the toe is closed.

The socks are sold at NC State bookstores and will also be given away at trade shows. Koozies® are also in the works. However, the goal of bringing the machine into the college goes beyond creating promotional items. The robot expands the hands-on experiences the school can offer its students. Graduate students Zoe Newman and Elizabeth Kirkwood have become the principal operators of the machine. The pair have taken the robot all the way from the initial programming stage through troubleshooting and fine-tuning to finished product.

The machine also benefits undergraduate students. “We had a project with the senior design group and textile engineering,” Newman says. “And they were looking for a few different variations of socks with different yarns. We were able to use the machine to help them with that project.”

— Sarah Stone, Communications Specialist, NC State Wilson College of Textiles

TEXTILES.ORG

TEXTILES.ORG