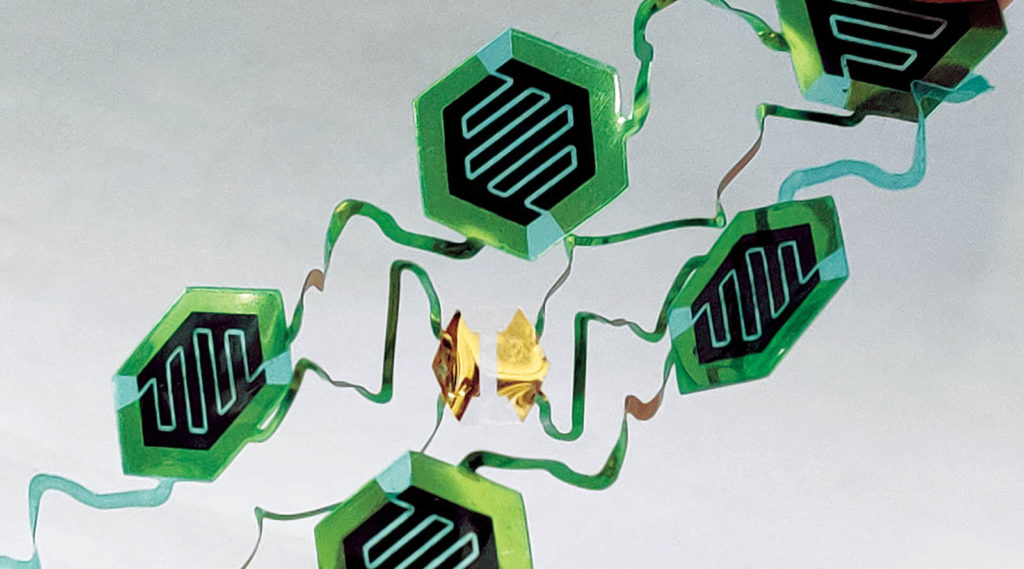

Engineers at UC Berkeley have developed a new technique for making wearable sensors that will enable medical researchers to prototype test new designs faster and at lower cost than existing methods. Renxiao Xu developed the technique while pursuing his Ph.D. in mechanical engineering at Berkeley. To achieve low-strain flexibility on wearable sensors, engineers use an “island-bridge” structure, Xu said. The islands house rigid electronics and sensor components, and the bridges link the islands to one another. Their spiral and zigzag shapes stretch like springs to accommodate large deformations.

In the past, researchers have built island-bridge systems using photolithography, a multistep process that uses light to create patterns on semiconductor wafers, but the method requires a clean room and sophisticated equipment. The new technique is simpler, faster and more economical, especially when making one or two dozen samples for testing.

TEXTILES.ORG

TEXTILES.ORG