As the e-textiles industry continues to grow, it will be essential to have consensus-based international standards to support the industry to ensure reliability of materials and products and best practices used in design and manufacturing.

As an industry trade association with decades of standards development for the electronics manufacturing industry, IPC International Inc. has a collection of more than 300 international standards. These standards represent collective knowledge and best practices from the supply chain and are used worldwide for designing and manufacturing electronics.

An open process

All IPC standards are developed and maintained by volunteers from the global electronics industry, and all IPC standardization activities are open to anyone for free participation. This ensures that IPC standards are representative of the industry at large, rather than the case of pay-to-play standards development, which may serve to benefit only the companies that can afford to play.

This approach has inspired the e-textiles industry to approach IPC as a home to develop international standards. Starting with one working group in 2017, the IPC E-Textiles Committee has grown to encompass multiple working groups developing IPC standards. These groups represent the full spectrum of those with interest in e-textiles technologies, from academia to materials suppliers, to integrators, to OEMs and brands.

Work in progress

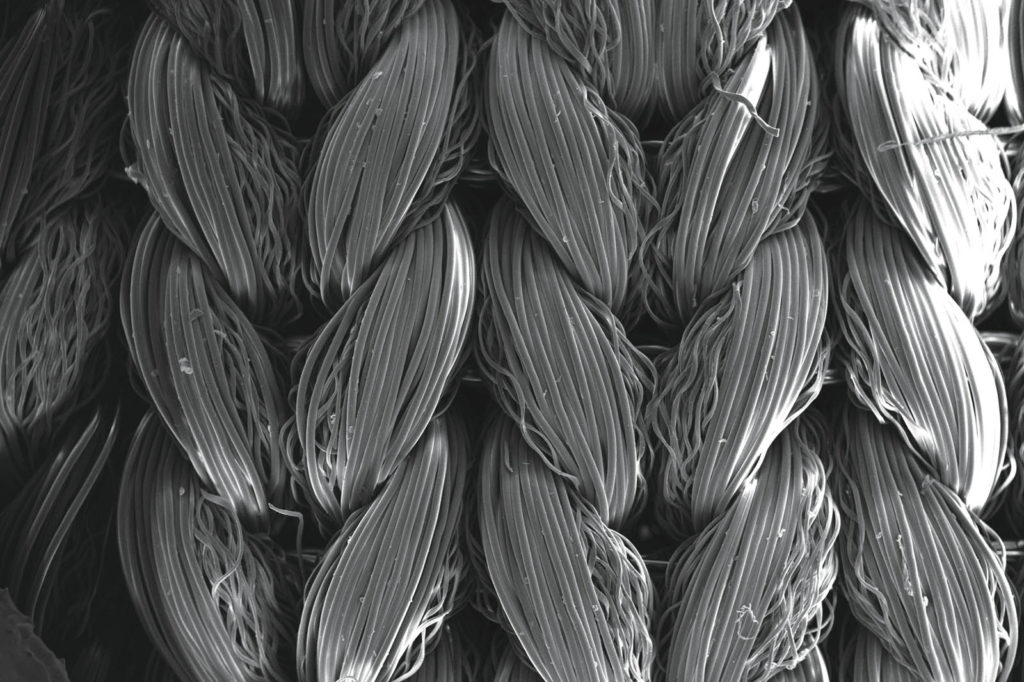

Two IPC task groups are working on standards for conductive yarns and woven, knitted and braided e-textiles, one of which is new and the other a revision of the first standard published by the committee. IPC/JPCA-8911, Requirements for Conductive Yarns for E-Textiles Applications, is being developed jointly with the Japan Electronics Packaging and Circuits Association (JPCA). This new standard will identify categories and establish the classification system, the qualification and quality conformance requirements, and the test methods for conductive yarns used in e-textiles.

The need for this standard arose out of the revision of IPC-8921, Requirements for Woven, Knitted and Braided E-Textiles Integrated with Conductive Yarns and/or Wires, and this new standard will also benefit new standards activities focused on embroidered e-textiles. The goal for this standard will be to have base test methods that any yarn supplier can use to show the electrical, thermal, mechanical and chemical exposure characteristics of its materials according to specific test methods. These will make it possible for customers to make “apples-to-apples” comparisons of materials.

IPC-8921A will establish the classification system as well as qualification and quality conformance requirements affecting electrical/electronic performance of woven, knitted and braided e-textiles integrated with conductive yarns and/or wires. This revision will reference many new IPC test methods for e-textiles durability, which are being developed jointly as part of the effort around IPC-8981 for wearables.

The task groups for these standards are led by Sahar Rostami of Myant Inc., and Joe Geiger of Bally Ribbon Mills.

Printed electronics

There are two standards and one IPC test method being developed for printed electronics for e-textiles systems. IPC-8952, Design Standard for Printed Electronics on Coated or Treated Textiles and E-Textiles, will establish requirements for the design of printed electronics and their forms of component mounting on coated or treated textile substrates.

The textile substrate could be a bare textile or an integrated e-textile (woven or knitted). The standard printed electronic design (SPED) classification from IPC-8952 provides a visual description for a designer to communicate to the manufacturer the printing process steps for building the design.

As part of the development of this standard, the task group developed IPC-8971, Requirements for Electrical Testing of Printed Electronics E-Textiles , as well as a new IPC test method, Conductor Temperature Rise Due to Current Changes in Conductors for Printed Conductor Materials on Textiles.

The task groups for these are led by Pratyush Rai of Nanowear Inc., and Chuck Kinzel of Liquid Wire Inc.

E-textile wearables

In late 2018, European e-textile companies and institutions formed a regional IPC E-Textiles Committee to discuss and debate standards needs in their region.

This led to the formation of a new task group that spent nearly three years working on IPC-8981, Quality and Reliability of E-Textiles Wearables, which will establish required testing and reliability expectations for e-textiles wearables products. This standard will set testing requirements for multiple mechanical and exposure characteristics that would apply to e-textiles wearables systems. These include acid, microbes, saltwater, perspiration, alkali, abrasion, stretch, torsion, flex endurance and washability.

During its work, this group also curated a plethora of content on e-textiles wearables. Since the reliability standard will be very brief and focus on the requirements, the task group did not want to have that information go unused, so a new task group is forming to work on IPC-8961, Guideline on E-Textile Wearables. This guideline will provide best practices and useful information for those interested in developing e-textiles wearables. This will serve as an educational resource, as well as a suitable supplement to users of IPC-8981 who may be looking for additional background information on the characteristics and testing of that standard.

Embroidered e-textiles

In early summer 2022, an interest group formed under the IPC E-Textiles Committee to discuss needs for standards for embroidered e-textiles. Over the course of several meetings, the group curated a list of gaps in standardization, focusing on materials, design requirements, reliability, integration methods and manufacturability.

An action team (IPC A-Team) from the interest group is working through that long list of topics to propose a plan for standards development to the full interest group. Any task groups that form for embroidered e-textiles will benefit from the work that has been done by the preceding list of task groups, which will have created new IPC test methods, set reliability expectations for products, and established qualification expectations for materials, which will help those groups speed the time to market for their standards.

Significant opportunities

Many other IPC task groups develop and maintain standards for additional topics of interest to e-textiles product developers, such as component assembly, conductive and dielectric inks, insulation materials and electronics design rules. These are existing, well-established standards in the electronics industry that are and will continue to be referenced from other IPC e-textiles standards and can also be used as a starting point for new IPC e-textiles standards.

Additionally, through IPC’s Factory of the Future Initiative, IPC task groups have also developed or are in the process of developing industry standards covering topics such as digital twin, supply chain traceability, model-based definitions for components, component-level authentication and cybersecurity. Many members from the IPC E-Textiles Committee are also involved in the development and maintenance of these standards.

IPC task group action teams (A-Teams) are small, highly dedicated groups of individuals that take on tasks such as developing draft content for IPC international standards and test methods and proposing resolutions or comments on draft documents for final consensus by the task group.

An individual or organization wishing to participate in the development of standards is invited to join one of the task groups. Those with the time and ability to play a more active role may also wish to consider joining an A-Team. These teams act in the spirit and dedication of standards development for the betterment of the entire industry.

Chris Jorgensen is director, Technology Transfer, IPC. He can be reached at ChrisJorgensen@ipc.org.

TEXTILES.ORG

TEXTILES.ORG