In 2021, attendees to the IFAI Expo in Nashville, Tenn., were cautious. We were all still wearing masks and practicing social distancing, and for some, the future was a bit uncertain.

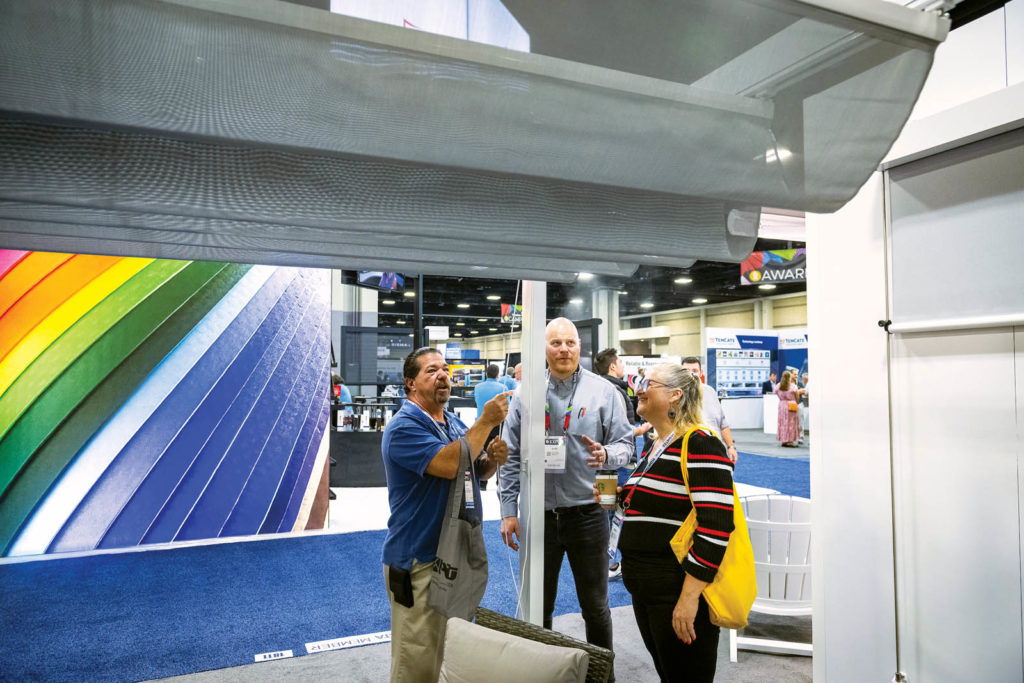

In contrast, IFAI Expo 2022 in Charlotte, N.C., was definitely more upbeat. One could sense that attendees were far more energized this year. You could see it on the show floor, at the networking events and in the education sessions. Attendees were eager to see what new products and services were being introduced and to learn about different ways to improve the way they do business.

In 2023, the newly rebranded Advanced Textiles Expo will be November 1-3 in Orlando, Fla.

High points and highlights

IFAI Expo keynote address Dr. Elliot Eisenberg answers “Are we in a recession?”

At the IFAI Expo keynote address, noted economist Dr. Elliot Eisenberg attempted to answer the question on everyone’s mind these days: “Are we in a recession?”

His answer? “We’re not in a recession yet… but we’re going to get there.”

The pandemic may be over, but the economy is sinking. Around 70% of U.S. Gross Domestic Product (GDP) is household consumption and, as the last of the COVID stimulus money exits the system, discretionary spending is rapidly drying up.

“Spending went crazy during COVID and we pulled forward a lot of demand,” Eisenberg explains. “Now people don’t want to buy things; they are shifting to spending money on experiences. We are seeing them pivot from buying goods to buying services.”

That’s if they’re spending any money at all on non-essential purchases. Inflation has caused real per capita disposable income to fall by $700 from pre-COVID levels, leaving many consumers unable to pay their bills. “Americans are charging things on their credit cards like there’s no tomorrow,” he notes.

But while the dollar may be weakening here in the U.S., other nations’ currencies are weakening more rapidly, causing a dramatic increase in demand for dollars as most international debts are denominated in dollars. This demand is pushing up the value of the dollar, and will continue to do so in the months to come. A strengthening dollar will create growing headwinds for U.S. exporters, particularly as the European Union, the U.K., Japan and others deal with a growing energy crisis and economic recessions.

But Eisenberg notes that there are some bright spots on the current economic landscape. Oil prices have come down significantly, which will help decrease shipping costs. Supply chains still face challenges but have noticeably improved. Trucking demand has softened, spot container prices have practically fallen off a cliff, and material costs will decrease going forward.

“Inflation will come down,” he says. “The question is how much and how quickly.”

Unfortunately, the good news did not extend to the labor market. He noted that there are currently 1.7 jobs per person in the U.S., due in part to so many Baby Boomers deciding to retire early as well as the 1.1 million excess COVID deaths, of which 400,000 were employees. The subsequent worker shortage is fueling the rise in wages, as are varying levels of inflation throughout the global economy.

As for when the recession is likely to begin, he predicted, “Typically, we see two years between rate hiking and the start of a recession. But the Fed is hiking very quickly, raising rates four times in four meetings, and will probably continue to hike them into 2023, so I think it will hit much earlier—sometime around the end of Q1, probably no later than the end of Q2 in 2023.”

However, he was quick to note that he doesn’t think it will be a very deep recession for the U.S. “Maybe 12 months,” he says.

Business

Considering outside sales? Read this first

In the education session “Oh Crap, Here Comes the Competition: Time to Add Outside Sales,” James Auerbach, VP, Event Segment, American Rental Association, discussed how to assess a company’s existing sales structure and determine whether and how to add outside salespeople. Auerbach says it’s first necessary to identify where you are and then decide where you want to go.

“I ask every business owner I meet to show me their list of prospects, and almost nobody actually has one,” says Auerbach. “This tells me they don’t have a formal sales program. You can grow organically for a while, but you eventually need a formal sales program.”

Auerbach says it’s time to consider adding an outside sale person once you start detecting warning signs in two categories: things you can easily see and things you can’t.

Things you can easily see include new competitors and new salespeople visiting your established clients. Things you can’t easily see include a decrease in phone calls, order frequency, website visits and order amounts.

When considering hiring an outside salesperson, Auerbach recommends three action steps:

- Review your market

- Review your existing team

- Review the people already in your orbit. Someone you already know might make an excellent outside salesperson for your company.

Cybersecurity basics: Don’t trust anybody

The overriding message of John Stengel’s session “Hacking the Supply Chain” was “Trust no one and verify everything.” Stengel, CEO and president of JSCM Group, which manages cybersecurity for companies and governmental organizations, says that in most cases you don’t even know your business is being hacked. “Most attacks happen over a week to 18 months,” he says. “By the time your computers are locked and hackers are demanding ransom, the damage is done.”

He says companies need to have a cybersecurity plan in place and must require the following items from their own company and each of their suppliers and vendors as well:

- Use the “Principle of least privilege.” Don’t give all your information away to any one company. Have zero trust of exclusive deals.

- Get third-party testing of your IT security, even if you have an in-house IT team.

- Get real liability insurance, not a rider.

- Ensure ISO certification of security systems.

- Use redundant vendors. Work with more than one company so you can avoid chaos if a particular vendor or supplier is a victim of a cyberattack.

Is your website sabotaging your revenue goals?

There are several reasons your business website could be working against you, says Goodshuffle Pro Sales Manager Mallory Mullen in her session “5 Reasons Your Website Is Sabotaging Your Revenue Goals.”

“Your website should act like a tour guide and tell customers where to go and what to look at,” she says. “Your site should be friendly to search engine optimization (SEO) to convert clients and attract new leads because it is so important for your website to rank well.”

Mullen says common mistakes business owners make with their websites include hiding their business location, not clearly listing all the industries they serve and avoiding a description of products and services.

“Clearly list the industries you serve because you don’t want to come across as a jack-of-all-trades doing everything for everyone,” she says. “And use bullets because people have short attention spans, and your information needs to be quick and easy to digest.”

Don’t hide prices because you are afraid of turning anyone off. You want to generate more leads with transparent pricing through clear expectations. The worst thing to do, says Mullen, is to create your website and then forget about it.

“If content is not fresh and relevant, what will that feel like to a customer?” she asks. Because outdated content knocks down a website’s SEO ranking, Mullen suggests updating content often with new inventory, new hires, best sellers, upcoming events, FAQs, testimonials, industry news and even something personal when appropriate because people love seeing the human side of a company team. “All of this goes into making your site a relevant entity,” she says.

The pricing game

Profit is not a dirty word, says Madeleine MacRae, founder and CEO of HomePro ToolBox. In a session called “Stop Playing the Pricing Game,” MacRae says the more comfortable you get with the money side of the business, the more comfortable you will get with communicating pricing to customers.

She says business owners must be confident about asking for what they’re worth. “Can you say with full confidence to customers, ‘My products and services are totally worth the full price?’ If you don’t believe that your products are worth the full price, then there’s no way your clients will believe it either.”

To increase sales, MacRae says business owners have to be unshakably certain about their value and persuade customers to invest more to get the quality and service they offer.

“If you can’t deliver premium quality, don’t charge premium prices. If you just deliver great quality, charge great prices. If you deliver luxury, charge luxury.” According to MacRae, there’s a price point for every client and a buyer at every price point.

“You need to choose and own your position in the market. You need to be able to articulate the value you bring to the table. Your ability to own and convey your value to your client is directly proportional to your sales results.”

During a recession, MacRae says, it’s even more important to protect your price margin. “People will want more time to make a decision,” she says. “Be sure to tell them what they will find when they look elsewhere and be ready to define your value for them.”

Managing Millennials

The biggest challenge most companies are struggling with these days is labor, says Tim Ledwein, president of Sandler by i10 Solutions. In the Expo session “Hiring and Managing Millennials and Gen Zs,” Ledwein said the extreme shortage of labor has resulted in mediocrity becoming the new level of excellence. “The standard for new hires has quickly been reduced to ‘Do they show up?’”

Finding, hiring and keeping quality employees is harder than ever, and according to Ledwein, the generational differences between employers and potential or existing employees can make it feel impossible. He says that different generations have different motivations. Boomers want a high quality of life and to create a legacy. Gen Xers want freedom and balance. Millennials want to be part of something bigger than themselves and Gen Zs want to make money and be who they are.

Ledwein says that aligning these motivations requires intentional communication with employees. “Employers don’t motivate teams; they motivate individuals and individuals move the team. If you don’t know what’s driving your employees, how can you hope to motivate them?”

Retaining a strong team

Clint Halladay, production manager at SewLong Custom Covers, says the subtitle of his presentation was essentially, “How we went from constantly hiring to building a group that felt like family.”

Halladay wondered why it was so hard for this industry to find and keep people, and his research revealed several reasons:

- There is a common perception that this is a job and not a career.

- Working with the necessary materials is hard on your hands (sewing).

- Some people can’t handle high standards and expectations and it’s stressful trying to learn everything.

- The pay needs to be higher.

- Every industry struggles with poor leadership and direction.

Halladay has advice for those in the industry looking for solutions:

- Put your people first.

- Create standards and clearly communicate expectations.

- Get to know your employees. Help them feel empowered and responsible for the success of the company.

- Solicit feedback and don’t let ego get in the way of hearing it.

- Don’t create hierarchies where employees feel separated from management.

The real secret, Halladay says, “Is to be the type of leader you’d want to work for.”

Advanced Textiles

Building a Flex Factory for textiles

Embracing new technologies as they emerge

by Marie O’Mahony, Ph.D.

“Designing is the easy bit, manufacturing is the hard bit,” offered Dr. Andre West at the beginning of his presentation, “Flex Factory, Innovation, Entrepreneurship and Sustainability for the Future.” Dr. West is director of the Zeis Textiles Extension at Wilson College of Textiles, which will be located with the Flex Factory at North Carolina State University (NC State). The name “Flex Factory” was chosen to reflect the need to embrace new technology as it emerges.

The factory will include classrooms, a showroom for manufacturers, vendors and others to display and demonstrate products, a prototyping area with cutting, sewing and spinning equipment, body scanners, 3D printers and other high-tech equipment, and flexible spaces for collaboration and sharing ideas.

The leading makerspace

The Flex Factory will house five model manufacturing and testing labs: spinning, knit, weave, dye/finishing and testing. With predicted revenues in excess of $2.5 million in FY2023, it is anticipated to attract hundreds of industry partners with revenues to fund seven graduate and 13 undergraduate students. The Flex Factory’s aims to be, “the world’s leading makerspace for entrepreneurs seeking to develop fiber and textile-based products and businesses.”

Digitization lies at the heart of the facility with a more user-friendly approach to body-scanning that can then be used for 3D visualization, pattern making and manufacture of garments. In this approach one uses self-scanning via smart phone, using automated pose guidance. Tension and pressure mapping are available to help guide and evaluate garment fit, saving prototyping time and material in the development stages.

First to launch at Flex Factory will be the print and dye technologies, which will be available in January 2023. Dr. West was excited to share the news that another Expo exhibitor, Twine Solutions, headquartered in Israel, would be delivering a machine to them the week following Expo. Twine offers a digital thread and yarn dyeing solution that is waterless and sustainable.

A single cone of white is unwound and passes through an inkjet print process with eight cartridges providing the ink. Colors can be drawn from a Coats Group catalog, or users can create their own. The thread or yarn passes through a drying chamber to dry and ensure that the color is fully absorbed. The final lubrication occurs as the fiber or yarn is being passed onto the spool or cone at the final part of the process. Providing access and training for sustainable technologies such as this brings benefit to the industry, young entrepreneurs, students and academia—a gain all round.

Dr. Marie O’Mahony is an industry consultant, author and academic. She is based in London.

Creating comfortable and effective wearables

In her presentation, Erin Parker, Mississippi State University graduate research assistant, addressed the issue of bringing together designers, developers and engineers to make e-textile wearables that better address their customers’ needs. E-textiles, she stressed, can be made into comfortable and effective wearables for applications in a variety of market segments. But it’s important to understand the particular needs of each one.

Using the phrase “athlete personas,” she discussed four types of “athletes” who may use wearables—sports, tactical, at-risk, and industrial—to make the point that each type has its own concerns. For example, “Sports athletes can be very superstitious,” Parker says, which affects their priorities and decisions concerning their interest in using wearables. This means that a willingness to trust in the data is among the considerations for the sports athlete.

A tactical athlete, such as a soldier, would more likely be concerned about security issues, effective placement of sensors, and high-risk or dangerous conditions. An at-risk athlete, on the other hand, will have a variety of needs, depending on the individual challenges of the wearer. It’s also important that the wearable is user friendly.

Regardless of the type of wearer, “The more you can integrate the technology in the garment so it isn’t seen or felt, the more likely it will be accepted,” she says.

A plan for achieving circularity

The question of achieving circularity was at the heart of several presentations at Expo’s Advanced Textiles Conference this year. Ben Mead, managing director, Hohenstein Institute America, explained Hohenstein’s program for helping companies establish a process toward achieving circularity. Mead started with the sobering fact that the textiles industry is not doing enough to reduce its environmental impact, and water risks are increasing, with a 21% increase projected from the period 2015 to 2025.

To help companies work towards a more sustainable future, Hohenstein has developed an “impact calculator,” a tool within its STeP certification program that’s designed to measure both carbon footprint and water footprint. Mead notes that STeP (Sustainable Textile (& Leather) Production) is “holistic, modular and includes continuous improvement.”

Sustainability and nonwovens

In his presentation, Tom Daugherty, deputy director of the Nonwovens Institute (NWI) at North Carolina State University, began with a startling statistic: 80% of consumer goods—excluding packaging—are disposed of after a single use. It is among the

range of sustainability issues that require comprehensive action.

“It has to be a multidimensional approach,” he says. “It can’t be just one thing.”

The National Academies have issued a challenge to design a future without pollution or waste, which requires a new paradigm, he says. The recommendations include:

- Redesigning products and their production processes for resource efficiency, longevity, reuse, repair and recycling

while minimizing pollution. - Quantifying and documenting life-cycle consequences associated with commonly used products, and the costs and benefits of alternative approaches to reduce pollution and waste.

- Quantifying waste-stream characteristics and identifying ways

to reuse or recover materials. - Identifying products that could be manufactured with recycled

and reused materials. - Developing new resources—recovery technologies and processes for cost-effective recovery of materials and energy from the waste stream.

In the world of nonwovens—and particularly considering disposables—that’s no small matter.

3D textiles

In the session “3D Printing and Advanced Textiles: Disrupting the industry,” Colton Mehlhoff of Stratasys HQ offered examples of how 3D printing is changing the textile world. From 3D-printed dresses to handbags and shoes, designers are finding ingenious applications for this technology. Almost all types of fabric can be 3D-printed on except leather and vinyl, as the ink must adhere to fibers.

New 3D printers have many more nozzles for extremely high resolution. UV curing is then used to set the ink. The end result is extremely rigid, but also very durable, to the point of being machine washable. The ink can also be printed in various densities or with air pockets that would allow for electronic devices to be wired into the fabric.

Improving PPE

Health-care and emergency workers urgently need personal bioprotective equipment that is reusable, antiviral and biodegradable—with reduced environmental impact. In a session titled “Development of Environmentally Friendly Biological Protective Textiles,” Dr. Gang Sun, a professor of fiber and polymer sciences at the University of California–Davis, discussed how advances in textile technology have created new biological protective functions on biobased polymers.

Pathogens can survive on material surfaces for hours and days, Sun says. Biostatic textiles, such as those used in surgical gowns, drapes and face masks, can prevent penetration of liquids but can still transmit pathogens through surface contacts. Sun says new biocidal PPE products have an active substance that quickly kills a broad spectrum of pathogens, including bacteria, yeasts, fungi and viruses. Importantly, with the use of chemical agents like N-halamine and daylight photosensitizers, this protection can be “recharged” after repeated use to restore their effectiveness.

Specialty Fabrics

Is your social media helping your business drive sales?

While you may think your business is doing everything it can to effectively use social media, Kelsey Adamson with Wray Ward Agency, and Ron Paratore with Trivantage presented several ideas in a campfire session called “Effective Ways To Use Social Media To Drive Sales.”

Adamson notes there are more than 2.9 billion Facebook users and 1.4 billion Instagram users. “Besides being free, Facebook is great for sharing work and engaging in groups like yourself such as awning makers or marine canvas and upholstery,” she says.

Adamson and Paratore recommend creating a Facebook business page that in many instances can even function as your company website to share teasers and then finished products when you have permission to do so. “The best time to post on Facebook is Tuesday between 10 a.m. and 12 p.m.,” Adamson says. “For Instagram, the best days and times to post are Monday at 11 a.m., Tuesday and Wednesday between 10 a.m. and 1 p.m., and Thursday and Friday between 10 and 11 a.m.

Paratore says that, more than ever, older people are using social media; he encouraged older business owners to start doing so as well to increase sales. “We can all learn to participate in this,” he says. “There are more 50+ people using social now than there has ever been because it is very effective and can drive engagement.”

Supply chain challenges

Supply chain delays and challenges are still one of the top issues facing the textiles industry today. A panel of industry leaders discussed the causes of these problems, the outlook for the coming year, and how companies can best prepare themselves to deal with shortages and longer production times. Mark Tyrrell, vice president of Lasalle Canvas Inc., served as moderator for “Supply Chain Challenges.” The panelists were Alex Petizian, supply management at Naizil Coated Fabrics; Jennifer Fennell, director of supply chain at Polo Custom Products; and King Mukherjee, founder and director of Global Impex USA.

One problem, all panelists agreed, is getting back to a “normal” balance of supply and demand, but that’s difficult when prices for raw materials, not to mention shipping costs, have fluctuated dramatically in recent years.

“We’ve got a huge influx of manufacturing being demanded in the U.S. and Canada, without the infrastructure to support that,” Fennell says. “Everyone is balancing, How much do we invest in this economy?” Labor continues to be tight and getting the machines to get a facility started is incredibly difficult, she says. “Everyone is asking, How long will this last? They are wondering when is manufacturing going to go to wherever the next low-cost manufacturing country is?”

The robots are coming

Sewing robots will one day replace humans in factories, says Frank Henderson, CEO of Henderson Sewing Machine Co., in a session called “Automation and Technology to Survive and Thrive.”

“Robotics and computer-enhanced machine technologies are beginning to come into use, reducing the number of workers needed for the production of clothing,” he says. But rather than eliminating worker positions, Henderson says the machines can automate the least appealing work, such as bobbin changing and skip catching, and get the best from employees. These “cobots,” or collaborative robots, are designed to share a workspace with humans, making automation easier than ever for businesses of all sizes. “They can even train people to operate them,” he says.

Henderson sees this technology being more widely used in textile product manufacturing. “Using robotic automation technology can change what you are doing, but don’t think it happens overnight,” he says. “You have to crawl before you can walk and walk before you can run—you have to take it one step at a time.”

Shade and Weather Protection

Put your best facade forward

In his session “Textile Facades vs. Metal Facades in Building Enclosures,” David Peragallo, tensile architecture business consultant for Serge Ferrari North America, explained why architects should consider the advantages of using a fabric facade as an aesthetic and bioclimatic solution over metal mesh panels when designing or refurbishing buildings.

Building facades are often made of metal mesh and, while they offer privacy, they restrict natural light and can also be quite heavy. They also have a higher environmental impact due to the multiple steps and energy needed to produce them.

Fabric facades, on the other hand, are lighter and have the advantage of being printable to advertise a business or stadium name. Fabric facades offer greater transparency so natural, filtered light can come through without glare.

“We spend most of our time inside buildings,” Peragallo says. “Light is a source of health.”

He shared statistics showing that allowing natural light in buildings is beneficial in a variety of ways. For example, he says, workers are 18% more productive when they have natural lighting. Memory and mental function may increase by as much as 25%. Students achieve 14% higher test scores, and retail sales may grow by as much as 40%.

Navigating the changing marine market

When Rick Berkey’s marine shop was closed for three months due to COVID-19 restrictions, “it became clear we couldn’t rely on marine work alone to sustain us and our employees during the ebbs and flows of market changes,” he says. Berkey is the owner of Rick’s Custom Marine Canvas and Sail Repair, based in Cornelius, N.C. He discussed the business changes he’s made during his Expo presentation.

For most of his 14 years in business, Berkey says he has concentrated primarily on marine canvas and sail projects. But once his shop opened up again during COVID, “the phones stopped ringing because so many consumers bought new boats that didn’t need my covers or canvas repairs.”

“We knew we had to do something different,” says Berkey. So, he started saying yes to covers for decks, grills and backyard sunshades and enclosures. Some local taverns asked him to make patio enclosures, and a real coup came when he was asked if he could sew webbing onto solar panels for the military.

“We started saying yes to projects nobody else on the lake would touch,” says Berkey. “I decided to take on all these custom projects because nobody knows what the future will bring.”

He encourages fabricators to expand into other markets using their existing skillsets. “Sew what you know, but don’t take on a new skill level unless you want to invest.” For example, he decided not to move into interior upholstery because he says he’s too slow and unskilled, so it wouldn’t be worth it to him financially.

Sustainability requires individual metrics

There is no doubt the world is warming, says Mar Ricketts, principal and founder of GuildWorks in Portland, Ore., which specializes in permanent tension fabric structures. Ricketts considers climate change a market opportunity for people in the shade and comfort industry. In his session “Warming Earth: The Need for Sustainably Designed and Built Shade and Weather Protection,” Ricketts projects 20% growth in the shade and weather protection industry in the next decade.

“Summers are getting hotter and it’s driving consumer interest,” says Ricketts. He points to new markets opening up such as wineries in the Northwest. “They depend on visitors, and nobody wants to sip wine with the sun beating down on their heads,” he says.

Ricketts encourages businesses to be more intentional when it comes to growing sustainably, which he defines as “meeting current needs without compromising the ability of future populations to meet their needs.”

Given that sustainability metrics are difficult to define, Ricketts says each business needs to create its own. The good news, he says, is that compared to traditional construction, lightweight fabric and membrane structures are already far more sustainable because they produce less waste, reduce transportation costs, have shorter construction time frames and produce less pollution.

Report compiled by Elisa Bernick, Tim Goral, Kevin Kerfoot, Jesse Madden, Marie O’Mahony and Janet Preus

Show photography © Mark Skalny Photography (except where noted) All Rights Reserved

TEXTILES.ORG

TEXTILES.ORG