Research into reactive textiles goes on around the world. At Aalto University in Finland, researchers have developed textiles that change shape when they heat up, thanks to weaving in liquid crystalline elastomers (LCEs). The work was done in collaboration with the University of Cambridge in England.

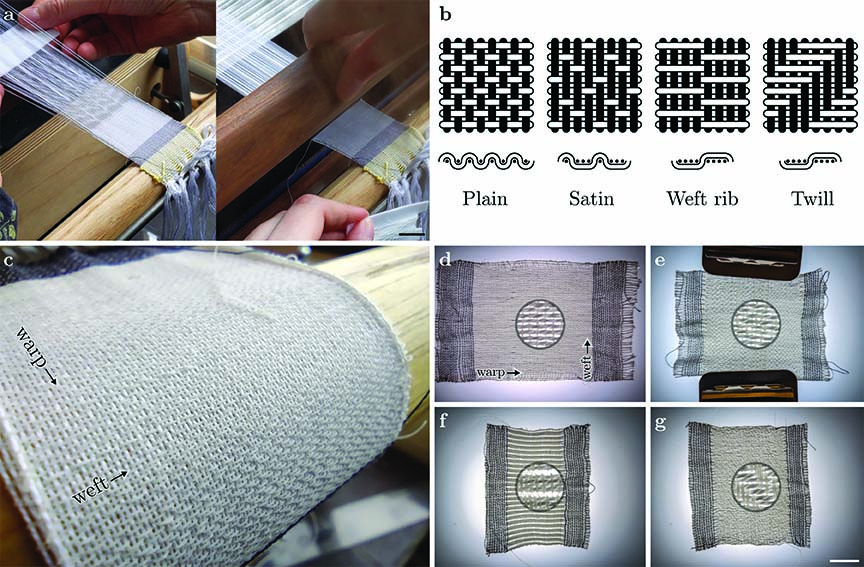

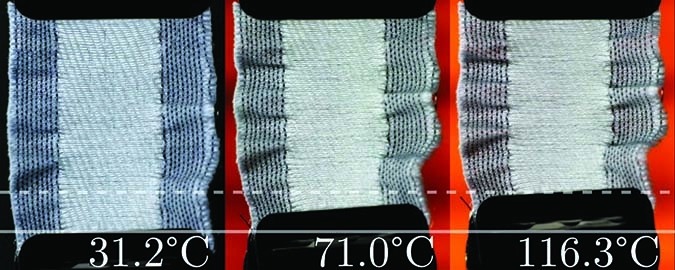

These LCE fibers, developed in the 1980s, have been used in soft robotics as thin films and can respond to heat, light and other stimuli. Previous research with the fibers has embroidered LCEs onto existing fabric, but the Aalto study authors actually wove them into the fabric on a standard loom. The study tested how soft or stiff LCE yarn fibers behave when woven into different patterns: plain fabric, satin, twill and a weft rib fabric, which were then heated with an infrared lamp.

“Active fabrics, responding autonomously to environmental changes, are the ‘Holy Grail’ of the development of smart textiles,” the study’s abstract begins.

Besides adjustable aesthetics, uses of stimuli-responsive textiles could include medical devices to monitor people’s health, improved insulation products and interior design products, such as for managing acoustics in a room.

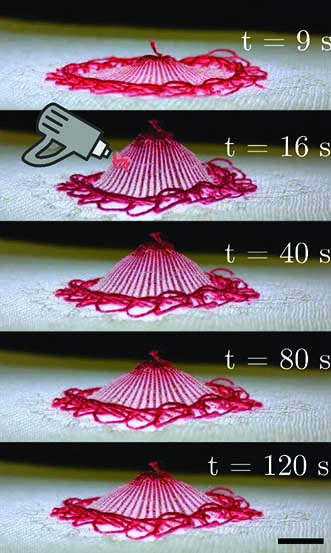

The fabrics contracted as they warmed and reverted to their original shape as they cooled. LCE yarn woven in a radial pattern contracted into a cone shape when heated.

“At first, the impact of using industrial textile techniques with these kinds of new materials wasn’t clear to us,” says Pedro Silva, a postdoctoral researcher at Aalto who led the study. “The elasticity of the two types of LCE yarn is comparable to spandex or even softer. That meant it was essential to understand if the textile industry could use these yarns and how the combination with conventional yarns would impact their movement.”

The findings were published in Advanced Materials in January.

The Multifunctional Materials Design research group “focuses on experimental studies of soft materials, as well as inorganic-organic hybrids,” the school site notes.

TEXTILES.ORG

TEXTILES.ORG