Outlast Technologies GmbH in Munich, Germany, has patented the procedure to adhere aerogel to nonwovens, enabling materials as thin as 1–3 mm to be well insulated and still soft and flexible. The treated fabrics, sold under the name Aersulate®, can then be processed conventionally and made into clothing, shoes, tents, pipe sheathing, insulation or window treatments or be used in firefighting equipment, vehicles, electronics, aircraft and more.

Anywhere insulation is needed in a small space could be a possible place to put Aersulate fabric; for example, a cell phone pocket in a coat could help preserve battery life in the cold or avoid it overheating in hot environments. The thermal resistance of Aersulate is more than double that of a comparable conventional fleece.

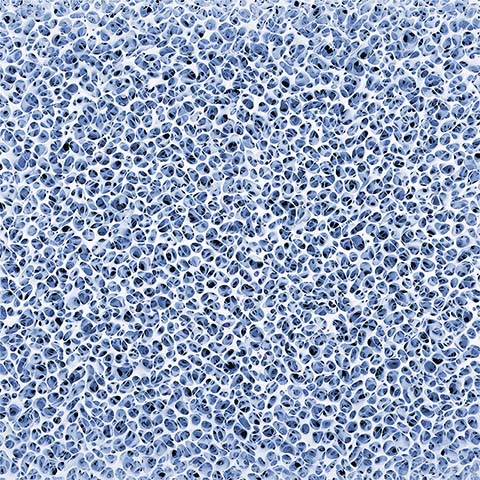

In the past, applying aerogel to a substrate meant that the product got rigid, as aerogel is made of quartz—even if it is 99.8% air. “The consistency of aerogel can be best described as liquid dust particles which spread uncontrollably throughout a room within seconds,” says Volker Schuster, head of research and development at Outlast Technologies. “This is why processing is a big challenge.”

The density of the porous substance is more than 1,000 times lower than glass manufactured from the same material. It’s been used by NASA for years, for example in the insulation of its Mars rovers.

“One liter of aerogel weighs just 50 grams (1.8 ounces),” says Schuster. “Just 10 grams of the material has the same surface area as a soccer field, though.”

TEXTILES.ORG

TEXTILES.ORG