Looking back, looking ahead: Textile industry trends

April 1st, 2024

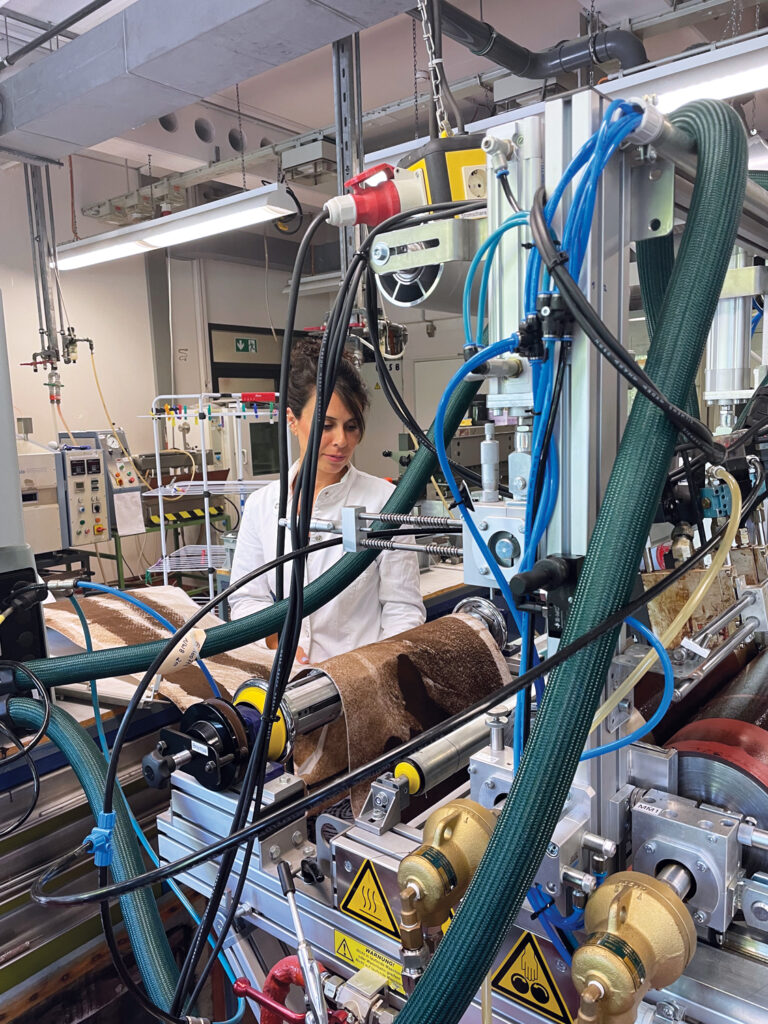

The German Institutes of Textile and Fiber Research Denkendorf (DITF) use a continuous coating line and thermoplastic processing methods to coat cellulose-based nonwoven fabrics with lignin compounds. Image: DITF A political, economic, social, technology (PEST) analysis on the smart and advanced textile industry for 2023 would likely show that “P” dominated, as politics has affected all […]

New smart textile fiber developed with recycled cotton

April 1st, 2024

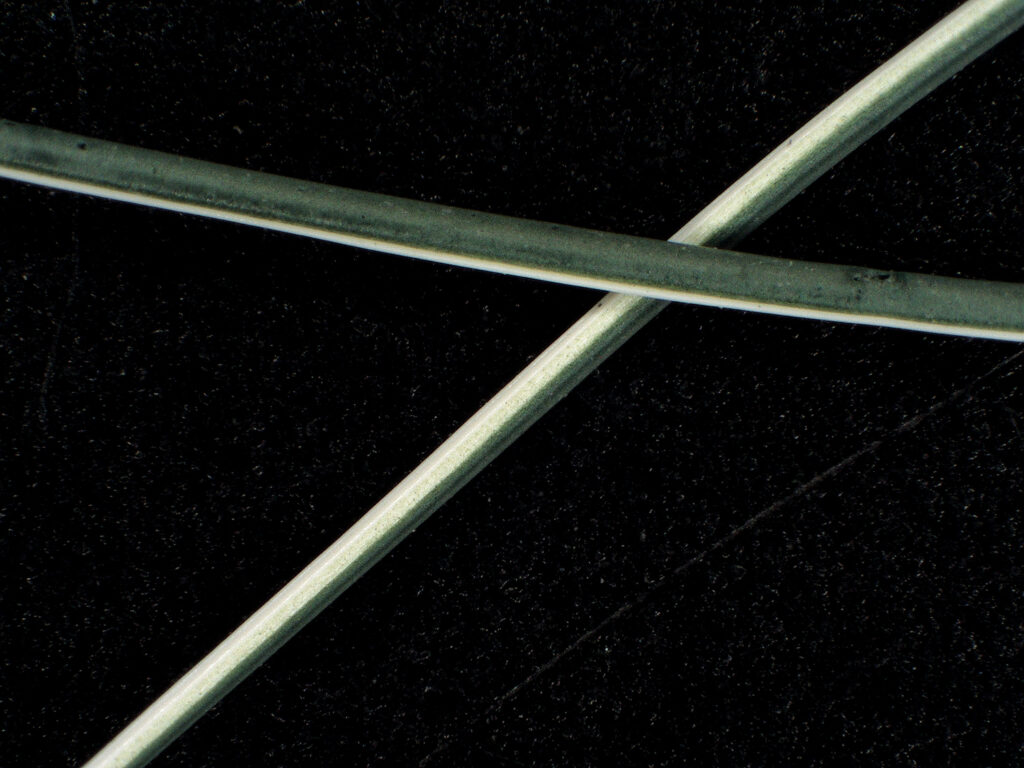

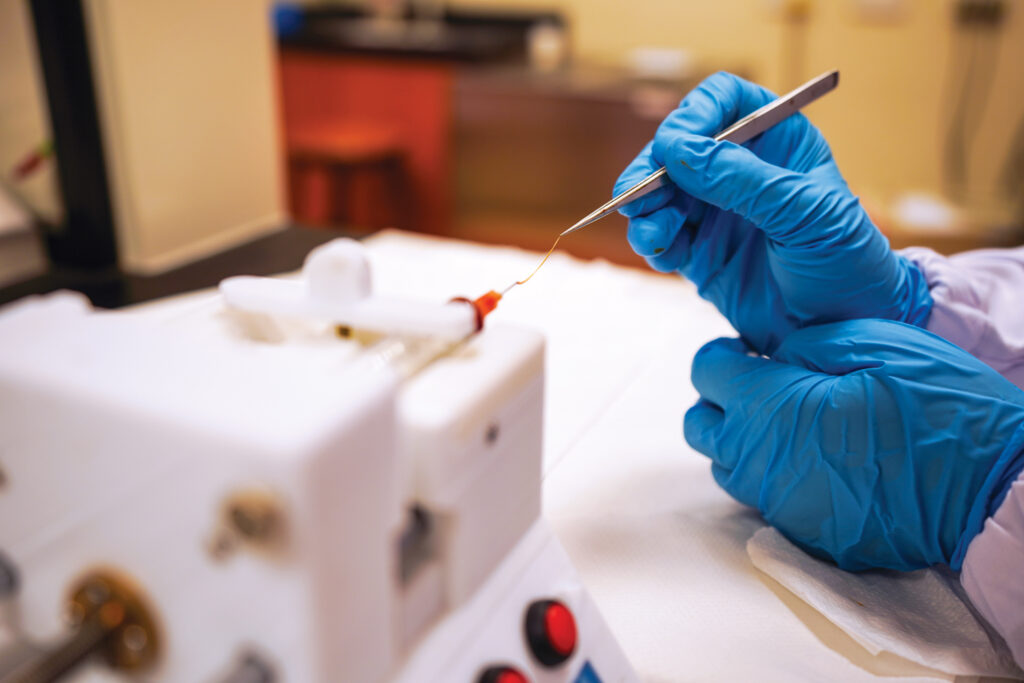

This composite conductive fiber uses two layers, one of recycled cotton-derived cellulose and the other of a cellulose and conductive polymer mixture. The fiber is formed through wet spinning. Image: Washington State University Researchers at Washington State University (WSU) have created a conductive composite fiber for smart textiles made from recycled cotton cellulose and the […]

Smart fabrics testing and standards under development

March 1st, 2024

A glove made on a Shima Seiki SWGN knitting machine on display at Advanced Textiles Expo 2023 in Orlando, Fla. The SWGN machine created the glove in 19 minutes at a speed of 1 meter (3.3 feet) per second, including a conductive yarn knit in the first two fingertips to allow the user to operate […]

Innovations in smart fabrics: Heating, cooling, bio-data collection and more via e-textiles

December 1st, 2023

A Loomia Electronic Layer (LEL) four-wire serpentine bus laminated onto knit fabric. The LEL was designed to be soft and flexible for use in smart textiles. Image: Loomia Technologies When is a jacket not just a jacket? When it can actually interact with the wearer’s body to warm or cool it or collect biometric information. […]

Spiders inspire smart textile fiber spinning method

December 1st, 2023

Drawing inspiration from how spiders spin silk to make webs, a research team from the National University of Singapore has developed a simple, efficient method to produce functional soft fibers that are suitable for smart textile electronics. Images: National University of Singapore In their efforts to develop a method to create soft fibers that are […]

Researchers test heat-reactiveness of fabric

June 1st, 2023

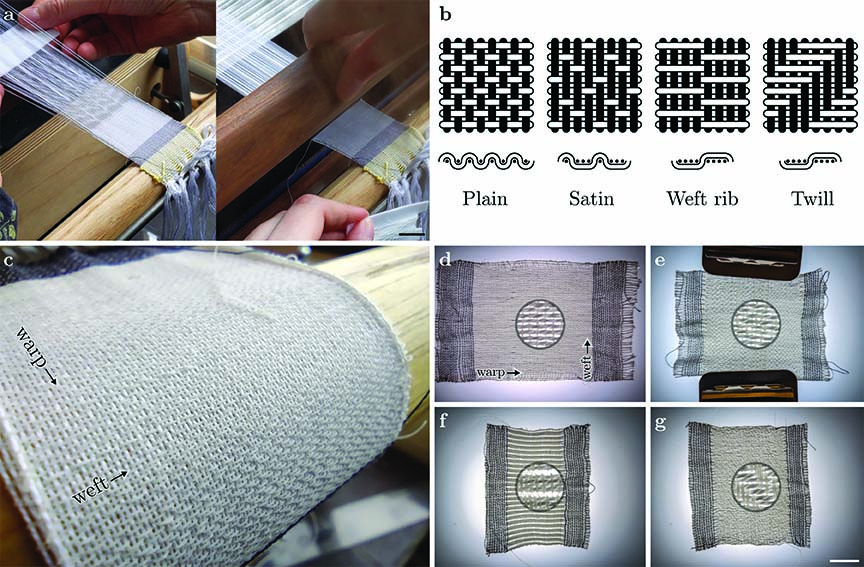

The different patterns created for the materials testing. Photos: Aalto Research into reactive textiles goes on around the world. At Aalto University in Finland, researchers have developed textiles that change shape when they heat up, thanks to weaving in liquid crystalline elastomers (LCEs). The work was done in collaboration with the University of Cambridge in […]

Fabrics heat and cool the wearer based on the environment

May 1st, 2023

Researchers at Shinshu University in Japan have developed a new method of integrating phase change materials (PCMs) within fabrics that could heat and cool the wearer depending on the environment. Occupations in many industries require workers to shift between vastly different temperatures as part of their work. Apart from making their work uncomfortable, such temperature […]

Motion and posture sensing textiles

September 1st, 2022

A form-fitting sock embedded with sensors can track the wearer’s movement and posture. Photo: MIT Researchers at the Massachusetts Institute of Technology (MIT) have come up with a novel fabrication process to produce smart textiles that can snugly conform to physical requirements by sensing the posture and motion of the wearer. By incorporating a special […]

Smart textile market outlook

April 30th, 2021

According to the report “Smart Textile Market Report: Trends, Forecast and Competitive Analysis” by ResearchAndMarkets.com, the smart textile market is expected to grow with a CAGR of 33% from 2019 to 2024. The study includes the smart textile market size and forecast for the smart textile market through 2024, segmented by textile type, function, end […]

German advancements in textiles

December 1st, 2020

Multiaxial fabric composite with fibers are positioned to optimize strength in this rear floor vehicle shell. This approach provides strength and rigidity only where needed, reducing overall material use and weight. The technology is an initiative of the Active Research Environment for the Next Generation of Automobiles (ARENA2036). Photo: Marie O’Mahony. Developments in technical textiles […]

TEXTILES.ORG

TEXTILES.ORG