Researchers at the German Institutes of Textile and Fiber Research Denkendorf (DITF) have developed tapes made from recycled carbon fibers (rCF) that have a nearly comparable tensile strength to virgin fibers. The rCF composite material is suitable for structural components for automotive, aircraft or wind turbine applications.

At present, most carbon fiber reinforced plastics (CFRP) have been landfilled or incinerated, or some have been downcycled to lightweight construction applications. Existing recycling shortens their fibers and tangles them, lowering their mechanical properties.

DITF researchers have been working for 15 years on adapting spinning processes to work with rCF fragments to untangle this problem. Now that recycling processes for CFRP have been further developed, the organization’s researchers have achieved the goal of creating a higher quality of recycled carbon fiber through making tapes.

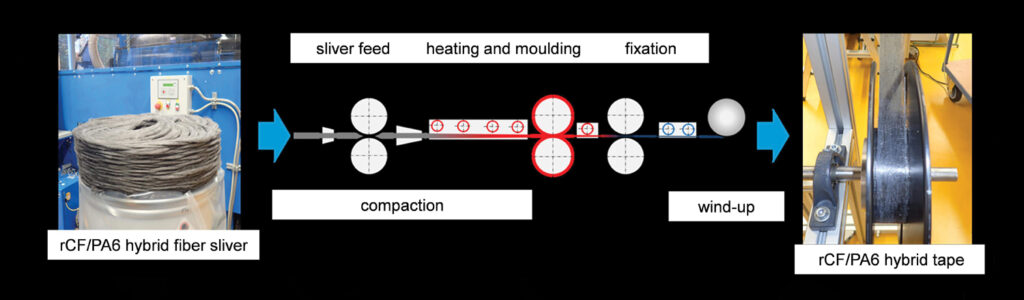

First, researchers opened the carbon fibers and mixed them with polyamide 6. This mixture was then separated and oriented in a carding and drawing process to create a fiber sliver. Researchers then drew the fiber sliver under tension to create the continuous tapes. Being able to restore the strength of the fibers by aligning them longitudinally is key to the material’s circularity. The tapes have 88% tensile strength compared to virgin fibers.

DITF estimates only about 15% of CFRP waste is recycled and that 8,000 passenger aircraft are expected to come out of service in Europe alone by 2030.

TEXTILES.ORG

TEXTILES.ORG