As the Specialty Fabrics Review turns 100, we honor the members, readers and contributors who help keep the industry a strong and evolving economic force.

For 100 years the Review has been the voice of the specialty fabrics industry—but it is the members of IFAI who helped to create and have supported that voice; it is the members who have changed along with the changing times. In celebration of the magazine’s centennial, and in appreciation of the people and companies who have made this magazine a leading resource, here’s a look at some of IFAI’s long-time members—readers of the Review who share thoughts about the ways they continually reimagine what their businesses can be, make changes, take risks and share successes and failures with other members of the specialty textile industry.

Laacke and Joys Co.

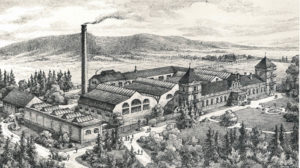

Laacke and Joys Co. LLC, now LJ Design and Manufacturing, based in Brookfield, Wis., has been a part of IFAI since 1912—IFAI’s longest-standing continuous member. Leaders in the company were also leaders in IFAI. Richard T. Laacke, who founded what was then the R. Laacke Co. in 1887, was one of the founding members of IFAI, and Richard Laacke’s son-in-law Harold C. Woehr, who later became president of Laacke and Joys, also served as president of IFAI and was an Honored Life Member.

Marsha Mather bought the company in 1996 and is the current owner. The company’s ability to stay in business and thrive owes much to great leadership that has not shied away from change. As fabrics have evolved—from cotton to a wide array of choices, including highly technical custom fabrics—the company has evolved along with them. Over the years Laacke and Joys has evolved from making awnings, tents, cow blankets, sails and boat covers into a custom job shop producing a variety of custom sewn products for OEMs.

The company’s 2012 acquisition of a 24/7, intensive-use dispatch chair company gave it a proprietary product line to manufacture and sell, which expanded its capabilities beyond sewn products. Laacke and Joys had been producing products from a location it had been in since 1960, and because of its growth, last year moved to an up-to-date, efficient manufacturing facility.

Advancements in technology and communication have contributed to the company’s growth—and the expectation of future growth. “The ability to exchange information electronically with customers has enabled us to do business not only out of our region of the country, but globally as well,” says Rachel Bares, vice president of LJ Design and Manufacturing. “The technology of 3-D drawings and 3-D printing could expand that even further over the next 10 years. Our biggest challenges going forward will be staying competitive and profitable while maintaining our promise of good wages and benefits to our employee partners.”

Glen Raven Inc.

Glen Raven started out as a cotton mill in 1880, but has evolved into an industry leader serving textile manufacturers across market segments and around the world. Though the company has experienced incredible growth, it prides itself on its attention to individual customers, helping them find solutions, including those for research and development, dyeing, spinning, weaving and finishing, and distribution and logistics. “Glen Raven has had the pleasure of serving an industry that is comprised of incredibly hard-working and entrepreneurial men and women who take great pride in both the products and services they provide for their customers,” says Allen Gant Jr., Glen Raven’s chairman and CEO.

Glen Raven has seen the industry through many changes, but Gant cites advancements in manufacturing equipment, polymer science and communication as current innovations having the greatest impact on the industry. “Better raw materials, new manufacturing techniques, tighter quality control and new communication tools mean that we can deliver better products exactly when and where our customers need them,” Gant says.

Glen Raven’s relationship with IFAI has been strong since it joined the organization in 1946. “From the very beginning, Glen Raven has been a staunch supporter of IFAI, its missions and its communication platforms,” Gant says. “The Review magazine is the authoritative publication for all who participate in this industry and serves as a great tool for learning and sharing.”

As global market developments and innovations continue to change the industry, Glen Raven’s strategy is to continue to let its customers’ needs lead its evolution. “We must anticipate, recognize and adjust to the forces shaping the business environment, the expectations of the consumers and the requirements of our customers,” Gant says. “Globalization is certainly an ongoing challenge, but listening to our customers and maintaining relationships are just as critical. The next 100 years are going to be an incredible time of transformation. We hope and plan to continue supporting our industry and working together toward common goals.”

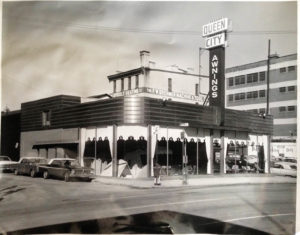

Queen City Awning

When Pete Weingartner’s grandfather bought Queen City Awning in Cincinnati, Ohio, in the early 1930s, he set in motion what is now a family legacy that centers on meeting customer and employee expectations. The company was started in 1877, and for 138 years it’s been providing awnings to the region. Originally it also offered horse and wagon covers, and later added patio furniture and tents, but now it’s back to providing primarily awnings and canopies—with the occasional specialized fabric industrial product.

A lot has changed for awning manufacturers since those early days, and technology is continuing to push the industry forward. Weingartner cites as a game-changer the advent of welding metal tube awning frames, allowing for greater customization and accuracy, versus the older pipe frames with fittings. He adds that advancements in laser measuring and cutting tools will allow for greater speed and accuracy in manufacturing custom products. “It seemed like when they first came out they were more for mass-produced projects and would be cost-prohibitive for custom manufacturers,” he says. “We haven’t made the decision to buy those tools yet, but we’ve looked into them and expect to make the purchase when the price comes down.”

Queen City Awning joined IFAI in 1930, and its relationship with the association—and Review magazine—has helped create networks for employees within the industry. “Of course you can now get a lot of information online, but one of the benefits of the Review is that it connects you to more than just the latest technologies and trends,” Weingartner says. “You also get to see the people behind the products, that you can seek out at Expo and find out how they did it. The Review magazine puts that connection together for the people in the industry.”

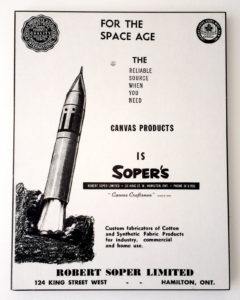

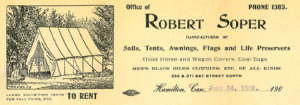

Robert Soper Ltd. (Soper’s)

Celebrating 140 years in business, Robert Soper Ltd.—now Soper’s Engineered Fabric Solutions—was founded as a sail-making business in Hamilton, Ont., Canada. Early products included coal bags, horse covers and tents, and during World War I, Soper’s provided gun covers and kit bags to the Allied forces. During the 20th century, the company earned its reputation as one of Canada’s leading awning manufacturers. Again recognizing the need to evolve, Soper’s entered into the industrial marketplace to provide fabric curtains, partitions and enclosures.

Owned and managed by the Gallagher family for three generations, Soper’s identifies itself as a company with traditional business values and ethics. “Our employees are the backbone of our business,” says Lincoln Gallagher, president. “From the plant floor to senior management, Soper’s maintains a customer-focused environment where the client is number one.”

More recently, industry-wide practices have put a stronger focus on employee safety and production regulations, and redefining standard safety applications is changing how many industries operate. “The health and safety of onsite employees has become paramount,” he says. “There is much more of a focus on air quality, ventilation systems and controlling noise, dust and fumes. Specifications and processes are being refined for non-industrial installations such as food packaging and pharmaceutical and there is a greater need for clean rooms, environmentally controlled sections and partitioned areas to ensure that cross-contamination doesn’t occur.”

oper’s has been a member of IFAI since 1953, and Lincoln Gallagher’s father, Tom Gallagher, served on the IFAI board. “IFAI is extremely important, as it brings together the industry to work as one,” Gallagher says. “The association is helpful for networking with fabric manufacturers to source new materials to meet new or modified specifications.”

Rainier Industries Ltd.

Tukwila, Wash.-based Rainier Industries, previously known as Puget Sound Tent & Awning, was founded in 1896 on the Seattle waterfront. The company began by providing tents and supplies for prospectors headed north for the Alaskan Gold Rush. Under the leadership of several owners Rainier Industries flourished, particularly during World War II when it negotiated large contracts to produce tents and tarps for the U.S. military.

In 1984 Scott Campbell, the company’s current owner and president, purchased Puget Sound Tent & Awning, and shortly after acquired Seattle Tent & Awning—the company’s largest competitor. The Rainier Wall Tent, first sold in 1897 by Seattle Tent, served as the inspiration when the company later changed its name to Rainier Industries.

The purchase of Seattle Tent & Awning was the first of 18 acquisitions under Campbell’s leadership. The most significant acquisition was Display Products, a company specializing in visual merchandising—an acquisition that brought in Starbucks and MDC Wallcoverings, which remain two of its largest accounts.

Campbell, who is now an IFAI Honored Life Member, served as IFAI chairman in 2007 and 2008, as the economy struggled through the challenges of a deepening recession. “Being 119 years old helps make Rainier unique,” Campbell says. “We have evolved from an organization driven by craftsmanship to one reliant on technology, automation and process. Still, we want to preserve the history of craftsmanship that defines and differentiates us. We are proud of our rich heritage of serving our customers. We realize it takes more than a long history to be successful; we must keep pace and adapt to a changing market, maintain the highest standard of quality and continually work to meet our clients’ expectations. We are committed to both our short-term success and to creating a lasting legacy.”

Cooley Group

Since its establishment in 1926 as a manufacturer of cotton awning fabrics, Cooley Group, based in Pawtucket, R.I., has continually evolved and expanded its portfolio of diversified products to include covers and liners for the world’s largest water reservoirs, geomembrane bladders for water and chemical storage for natural gas fracking, and non-PVC fully recyclable billboard print media for outdoor advertising.

Throughout its history, Cooley has developed product solutions aimed directly at the needs of its customers. Armed with a state-of-the-art R & D Innovation Center and three manufacturing facilities in the United States that are ISO: 9001 and 14001 certified, Cooley has a long and varied history of industry firsts, including becoming the first thermoplastic roofing manufacturer in North America (1977), the first company to introduce DuPont™ Kevlar®-reinforced TPU for oil booms (1983), the first company to develop PVC billboard substrates for the outdoor advertising industry (1993), and the first company to manufacture a heavy denier leno fabric for geomembranes, bermliners and oil booms (which became the product of choice for containing the BP oil spill in the Gulf of Mexico in 2010). Another notable accomplishment was collaborating with Dow Chemical to develop a proprietary print media to wrap London’s 2012 Olympic Stadium—part of an initiative to create the most sustainable Olympic Games in history.

Cooley will soon be celebrating an anniversary too—its 90th—and has been a member of IFAI since 1936. “In addition to input from our customers, the Specialty Fabrics Review continues to be an invaluable resource for industry trends and developments, and in particular to where the industry is heading,” says Dan Dwight, Cooley’s president and CEO. “It helps complete the picture of what the industry may look like in upcoming years, and given the intricate diversity of our full product line across four divisions (building products, commercial graphics, engineered membranes and technical textiles), the Review’s breadth is expansive enough to provide us with game-changing industry knowledge across the market segments we serve.”

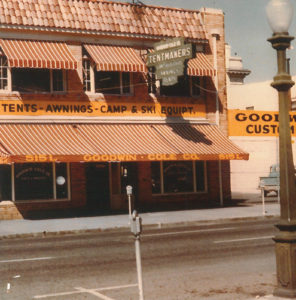

Goodwin-Cole Co.

Goodwin-Cole Co. began producing canvas tents and awnings in 1888 in Kansas City, Kan., before the company migrated to Sacramento, Calif., in 1920. At the time the company was known as Carnie-Goodwin-Pendleton Co., before it changed to Goodwin-Cole in 1952 when Robert Cole became a partner with Tom Goodwin. In 1953, the company joined IFAI and has been actively involved ever since.

Reinvention has been the norm for this company that embraced its home in the United States’ West. In its early days in Sacramento, awnings were in demand to protect homes and businesses from the intense heat. As air conditioning became prevalent, the demand for awnings dwindled. Demand is back as people recognize the energy efficiency and environmental sustainability awnings can offer, as well as beauty and curb appeal.

Although awnings have always factored heavily into the company’s inventory, Goodwin-Cole has branched out in a number of directions over the years, including providing agricultural covers to protect crops from frost, tents for migrant workers before permanent housing was provided, and ski and sailboat equipment for recreation at Lake Tahoe. One of the company’s more visible custom projects was a tipi for a display at the Smithsonian Museum in Washington, D.C.

Robert Cole (who served as president of the company for many years and as president of IFAI during the years when it changed from being the Canvas Products Association International) still serves as chairman of the Goodwin-Cole board of directors and takes an active interest in the health of the industry (see “Demand + Supply = Prevail” in the October issue). “As long as you recognize the challenges that are facing the industry and the business, you can address them and be successful,” Cole says. “I feel that in any business, the key factor is service. You have to work with and for your customers. Associations like IFAI and the ethical, capable suppliers we have available to us—these are the things that keep the industry strong.”

Sattler Corp.

Founded in 1875 in Graz, Austria, Sattler Corp. develops and produces high-quality outdoor fabrics as well as PVC products for applications such as truck tarpaulins and textile architecture. Sattler products are sold on every continent, and in 2010 Sattler acquired the U.S. company Outdura, expanding its reach even further. Sattler attributes its longevity to “offering the best products, staying in contact with the clients, solving problems in the right way, and never stopping working on new solutions—that is Sattler’s secret,” says Steve Weiss, vice president of sales and marketing, awning division of Sattler Corp.

Weiss points to new materials and new constructions, including pergolas, as benefiting industry growth. Sattler developed a new acrylic fabric called Lumera, which it launched in 2010. Lumera is woven with CBA, a fiber developed by Sattler, and is characterized by brilliant colors and an increase in cleanability due to its tighter weave. “We’re making new roads in the sunshade business with this development,” Weiss says.

The development of new construction applications are among the challenges the industry is facing, according to Weiss. The challenge for the fabric is that it should still look good despite the added stress. “The projects are getting bigger and bigger, and motors are getting stronger and stronger—and the fabrics should look perfect all the time,” he says.

Issues of global environmental responsibility and sustainability are prime concerns, and Sattler is addressing them by using “green energy” in its production line and implementing an aggressive recycling protocol. The company holds two of the most recognizable ISO certifications—9001:2008 for quality management and 14001:2004 for environmental management.

“Sattler has been a member of IFAI for many years and is proud to be a partner,” Weiss says. “IFAI plays an important part in our growth, and participating in Expo gives Sattler an advantage. It is money well spent!”

Awnings by Bigley and Hogshire

Launched along the Norfolk, Va., Roanoke docks in 1898 by Edward Hogshire, Hogshire Industries (now Awnings by Bigley and Hogshire) specialized in producing canvas riggings for Chesapeake Bay work boats. As demands changed, so did the company. It evolved from making riggings to marine hatch and industrial covers, to awnings and canopies and a variety of other custom textile products. Hogshire products have even made their way into a NASA space flight.

The company became Awnings by Bigley and Hogshire in 2010 when its owner and president Russell (Happy) Hogshire passed away and current president Taylor Bigley took over the leadership. As members of the association since 1923, both company leaders were instrumental in the development of what is now IFAI; Edward Hogshire played a part in forming the National Tent and Awning Association, and Happy Hogshire served on the board of IFAI.

One of the ever-present challenges the company faces—as do all custom manufacturing businesses—is deciding when to adopt technology and invest in new equipment. “Conservative leadership leads to longevity, but bold and sometimes risky moves lead to prosperity and success. The balance is what we seek,” says president Bigley. “The lackluster economy for the last seven-to-eight years has stifled our confidence and daring. We have continued to grow every year, but not without sacrifice, and this growth has not led to any great confidence. If Washington D.C. politicians would get out of the way, business and the marketplace would rebound.”

“The Review magazine has helped us stay ahead of the curve,” Bigley says, “introducing us to new products, technology, and giving us other points of view. It also makes us realize we are not alone. There is no blueprint for success in the awning and fabric world. By reading about others’ successes and failures, we can apply our own ideas and work ethic. That is why the Review is so important.”

TEXTILES.ORG

TEXTILES.ORG