If it looks green, smells green and feels green, it must be green. Right? The answer, it turns out, is more complex. It is common knowledge that green technology has large positive environmental impacts: large-scale energy savings, runoff reduction and heat reduction among their chief assets. As green builders continue to define the standards and guidelines for sustainable construction practices, different levels of earth-friendly products continue to circulate through the market. Green roof designers in particular are taking a hard look at the sustainability of their component materials.

Companies use sustainable green roofing products

Brad Budde of Conwed Plastics, Minneapolis, Minn., believes that the future development of sustainable green roof products lies in the hands of builders. He suggests that as companies continue to understand the commercial concerns regarding the application of sustainable and earth-friendly products, the market as a whole will become more educated about their applications, benefits and uses.

“Conwed works very diligently on two fronts with our biodegradable and earth-friendly materials,” Budde says. His company is a leader of earth friendly, compostable packaging materials as an alternative to traditional plastic bags, as well as biodegradable plastics that don’t leave the harmful, long-lasting resins of other industry plastics. “It’s a really great product that solves some of the disposal concerns for traditional plastic products,” he says.

One of Conwed’s most earth-friendly products is its erosion control blanket netting. While not typically used in green roof applications, it is nonetheless a big step toward creating holistically green products. “The temporary rolled erosion control products are meant to stabilize the ground until vegetation comes in and provides natural stabilization,” Budde says.

Jeff Stillman of ZinCo USA, Newton, Mass., says one of the keys to his company’s sustainable green roofing products is the use of non-rotting, recycled polypropylene. The substance’s long-lasting capabilities and recycled nature make it a shoo-in for sustainable building material. “It’s the fabric that we use for our protection mat and filter sheets,” Stillman says. “The mat is needle punched and usually made with a fleece backing composed of recycled polypropylene fibers.”

Carlisle offers green products

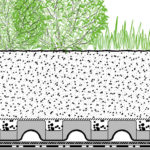

Carlisle SynTec, Carlisle, Pa., has an entire manufacturing sector for its Roof Garden materials. The company creates green roofing layers that include a drainage board, protection fabric, root barrier and moisture retention mat all made of mostly recycled polystyrene and polypropylene material.

The drainage board is of particular interest. Used as an alternative to drainage gravel and a supplement to protection fabric, Carlisle SynTec’s MiraDrain HC drainage board is made of high-impact polystyrene covered by non-woven polypropylene filter fabric. Similarly, the company’s root barrier product, the GeoMembrance™, is made of non-reinforced polypropylene fabric.

Plants used for sustainable roofing projects

Sustainable materials aren’t confined to the base level of green building projects. When it comes the greenery on a green roof, plants come into play. Ed Snodgrass of Emory Knoll Farms in Maryland has provided plants for 268 roof projects, providing more than 2 million square feet of green roofing in the U.S. Snodgrass’ farm collaborates with several university research programs. The effort is producing a fund of knowledge about soil depths and plant types that create healthy, lasting and sustainable green roofing projects.

The Emory Knoll farm employs photovoltaic panels, bio-diesel engines and composting toilets, all to save and create sustainable energy. All of the farm’s plants are chemical free. “We try to produce as much energy as we can,” Snodgrass says. “So as we can afford to make capital improvements, we want part of that capital to go to energy production of some kind.”

Jake Kulju is a freelance writer based in Providence, R.I.

TEXTILES.ORG

TEXTILES.ORG