How fabric technology is protecting rescuers against ever-more-dangerous situations.

How fabric technology is protecting rescuers against ever-more-dangerous situations.

On the hot summer day in 2013 when 19 experienced firefighters lost their lives, the Yarnell Hill fire, northwest of Phoenix, Ariz., spanned 8,400 acres. The trees were dry, the humidity was low and the wind suddenly turned, cutting off escape and creating an inferno. The men—members of the Prescott, Ariz., Fire Department’s Granite Mountain Hotshots—deployed their emergency shelters, but it wasn’t enough to save them. This is the type of tragedy that engineers and fabricators who work on safety and protective gear for extreme situations contemplate every day.

Some fibers can fulfill the dual purpose of being heat resistant and flame resistant at the same time. For example, Nomex® and Kevlar® (two of the most commonly used technical fibers in firefighting gear) can do both, up to about 600 degrees. But the temperatures at the Yarnell Hill fire reached 2,000 degrees—enough to melt the fire trucks. That’s an extraordinary challenge, and one that materials scientists are looking for ways to meet.

Scientists know of a few materials that can—in some cases, at least—resist these extreme situations. But it’s one thing to have them and quite another to deploy them in a meaningful manner. Some obstacles include comfort, breathability, manufacturability, weight and cost of the finished product.

According to the National Interagency Fire Center, 2015 was the most devastating year for wildfires since at least 1960. The next few fire seasons may be even worse. The problem is urgent: like workers in police, military, industrial and emergency medical environments, firefighters need better gear. Can we give it to them? And if so, how?

Effective, but not wearable

When comfort is no object, engineers can design textile products to block extreme conditions with relative ease. Dr. Barbara Pause, founder and CEO of Longmont, Colo.-based Textile Testing and Innovation LLC, specializes in phase-change materials that can absorb, store and release large amounts of latent heat without changing their own temperature. She offers the example of a warehouse fire curtain.

“When you have two warehouses next to each other and you have an opening in between, some companies will install a fire curtain in this opening so that the fire cannot spread from one warehouse to the next,” she says. “With phase-change material, you can keep the temperature constant for maybe 30 minutes or an hour or so, and it’s very effective.”

But that effectiveness comes with limitations. The phase-change material is integrated into a silicone matrix, which isn’t breathable and offers no moisture management. Making it into a fire curtain is no problem, but it’s not suitable for a garment.

“People would get protected, but at the same time they would probably take off the jacket for a period of time because they get wet underneath,” she says. “You can have a good product that’s not actually suitable for all kinds of applications. Often the protective garment area is more difficult.”

That’s Pause’s challenge going forward. She says the phase-change material, in the form of a fine powder, can be added to an adhesive and applied to a fabric. Some companies claim to offer breathable adhesives, which could be part of a potential solution.

“We are working on this with a company in Canada,” Pause says. “In the oil and gas industry, they have people working on gas pipes where there could be flames or hot gases. We are trying to develop a garment that is not too heavy and is kind of breathable, but also has backup protection. Right now, what they are using is Nomex suits, and the Nomex is a kind of protection, but it’s not enough.”

Connie Huffa, president and executive textile engineer at Fabdesigns Inc., Encino, Calif., says besides not being breathable, many protective fabrics are just unpleasant to touch.

“You have something that might be very flameproof, but if you’ve ever felt a fire hose, you don’t want that against your skin,” she says. “It’s very scratchy, and you need it so densely woven or densely knit that you have basically no air in between.”

Comfort counts

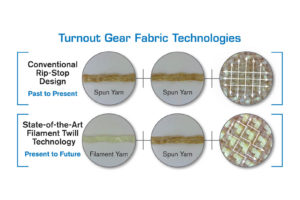

Companies are trying to solve that problem in multiple ways. Some, for example, have engineered new fabrics that don’t have that heavy, stiff “fire hose” feel. Greenville, S.C.-based Safety Components has engineered what it calls Filament Twill Technology™, a mixture of filament and spun Dupont™ Kevlar yarns woven in a twill design. Filament Kevlar yarns are more than twice as strong as spun yarns, so the fabric performs well without being inflexible and heavy, and it is softer, improving comfort and mobility.

“Before, it used to be just about durability and protection, but now comfort is suddenly a huge part of the story,” says Guy Lucas, Safety Components’ director of sales and marketing. “If a garment isn’t comfortable, people may take shortcuts or not wear it exactly how it’s supposed to be worn. That’s why comfort is important both in the industrial market and in the fire service.”

Layering is a complementary approach to the same issue. Need a heavy, dense flameproof fabric? Put a layer of it on the outside, not next to the skin. Then add other thin, layered fabrics inside to build up multiple attributes while keeping the garment agile and comfortable.

“We’re working with different types of spacer fabrics,” says Huffa. “With a spacer fabric, you have two faces and you have an interior, and if you construct it well, you can have dead air space in there [for insulation]. We actually worked with a fabric construction where we have 13 layers in a spacer. Each layer has a different purpose, whether it has to do with taser protection, or whether it has to do with being laceration-proof.

“You’ve got Kevlar going on in there as well, you’ve got Pyron®, [a flame-resistant fiber] which is no-drip, and then you have some other types of fibers, which are dissipative, and a few other things happening in there.”

Even the most protective materials benefit from being layered. Ceramic, for example, can survive the sorts of temperatures that killed the Prescott firefighters. But it burns hot while it’s doing its job, and it releases a lot of energy. Any garment that used ceramic technology would need to have additional layers inside to dissipate that heat and protect the wearer.

Man and machine

Even setting aside the heat-dissipation problem, ceramics aren’t yet ready for prime time when it comes to protective gear. Huffa says if she had the time and money, she’d try to engineer a portable, lightweight shelter using ceramics that could withstand temperatures of 2,000 degrees Celsius. It would be useful for firefighters, the military and aerospace/outer space. But right now, commercially available ceramics are simply too fragile to weave.

Carbon fiber, too, is problematic. “I can’t run carbon fiber,” says Huffa. “I’ve done it, and what happens is it becomes very brittle and it gets lodged in the machine, and there are black fibers. It goes in the yarn feed systems, it goes inside the needle bed. You basically have to strip the machine down, which can take three days, and clean it out before you run anything else.”

She says she’s looking at a company that makes a pre-impregnated fiber in which carbon is bound with another type of material. She’s hoping that will help it bend without breaking and contaminating the entire manufacturing area.

But the good news is, advances in knitting-machine technology have opened up many possibilities that weren’t available even five years ago. The computer systems are better and, on average, the mechanics are about 15 percent faster than they were in 2006. Machines with overhead feeds and feeders that are completely independent of the carriage system save even more time.

“I can get 32 feeders on the machine, which means that I can run things vertically, I can run things horizontally and diagonally in the fabrics,” Huffa says. “I can create meshes inside fabrics. I can use silver-coated yarns or stainless steel. I can integrate different types of wires and fiber optics. Pockets come right off the machine, so I can create pouches for electronics, sensors or formed pieces such as pieces of carbon fiber.”

Critically, for these life-and-death applications, new knitting machines remove human error from the garment-making equation. The protective features are always in the same place, and the tension and thickness are always constant. As long as the machines are calibrated the same, fabricators can run 100 machines or 1,000, all making the exact same garment at the same time. And constructing these complex garments is far cheaper than it used to be.

According to the National Interagency Fire Center, 2015 was the most devastating year for wildfires since at least 1960. The next few fire seasons may be even worse. The problem is urgent: like workers in police, military, industrial and emergency medical environments, firefighters need better gear.

Sixteen tons

One way fabric engineers can reduce the weight of safety and protective gear is to map where certain protective components are most needed. Then, using the newest construction technologies, they can incorporate special fibers and features only in those areas and nowhere else. Kevlar can go in areas that are more impact-prone. Padding can be concentrated at the knees and elbows. Phase-change materials can be built into the palms of gloves to ward off burns.

Wicking fibers are commonly built into the inner layers of protective gear to provide moisture management, but they don’t have to go everywhere. Sweat mapping—for each gender individually, since men and women don’t always sweat in the same locations—can help designers place these fibers only where they’ll be most effective.

Use of phase-change materials can help reduce the overall weight of a garment because these materials sometimes take the place of two or three layers; garments can be made thinner and offer the same amount of protection; or they can be made the same thickness but be more protective.

Incorporating technical materials is an eternal balancing act, with designers considering both weight and expense. More generous use of an expensive technology can make a garment more durable and safer for the user. But will it be too expensive for fire departments, units and precincts to buy? Will it end up weighing so much that end users will leave it hanging open on the job?

“Often, there’s a pricing issue because companies often buy the minimum or the lowest price that will satisfy their standards,” says Pause. “The more sophisticated the garments are—sophisticated phase-change materials and eutectic materials—the more the price goes up.

“And then you have to incorporate them into a matrix and put them on a carrier material such as a Nomex, and then you have a weight issue too. You really have to convince your buyers that the protection increase is reason enough to buy the stuff.”

But it’s so important, and firefighters aren’t the only ones working in extreme situations. Operating theaters, oil rigs and police precincts all present their own kinds of hazardous duty. The people who work there need to be comfortable, agile and alert. Next-generation safety and protective gear can keep them that way.

Jamie Swedberg is a freelance writer based in Woodville, Ga.

Sewing fire safety for structures

Makers of personal protective equipment must balance the ability of materials to resist fire and other hazards with the suitability of those materials to actually be worn by human beings. So you’d think a manufacturer of Fiberglass™-backed aluminum fire shields, which are deployed to help save houses and other structures during a fire, would have it comparatively easy.

But the devil is in the details, says Dan Hirning, owner of Firezat Inc., San Diego, Calif. For a while, Firezat manufactured large fire shields that were sewn together with Kevlar® thread. The company now prefers to offer standardized, reusable fire shields in a smaller 5-by-150-foot size. During deployment, multiple shields are overlapped and individually secured.

The change was due to manufacturability and cost, says Hirning. “Aluminum is a metal, and it reduces the flexibility,” he says. “The larger size fire shields are essentially like sewing large sails for a boat. You can bunch the nylon material to facilitate sewing, but even using long-arm commercial sewing machines, it was very labor intensive to sew the aluminum shield panels together.

“If you think of a nylon sail that you’re pulling through a sewing machine, you can bunch it all up on the inside as you make the seam.

“We have long-arm sewing machines that we use, but it’s still difficult to get much material underneath so that you can sew the panels together. So even though the larger shield facilitates an easier deployment, it was more expensive. It was cost prohibitive for the individuals who wanted to purchase it.”

Weight must also be considered. Even though humans don’t have to wear the product, they do have to carry it. “We try to keep them to 70 to 75 pounds at the most,” says Hirning. “They’re often helicoptered in with hotshot crews and fire crews. Then two firefighters will have to carry the fire shields to the structure they’re trying to protect. You have two people carrying this 75-pound thing up or down a hill. Any more [weight] than that, it’s too much.”

On the manufacturing side, the weight of fire shields is determined by the optimum thickness of the aluminum and the fiberglass substrate that is used for structural integrity and to keep the material from tearing. It must be thick enough to reflect 95 percent of radiant heat, but not any thicker or it would be pointlessly heavy. The fiberglass substrate adds weight, as well, but its presence is nonnegotiable. Without it, the fire shields would tear like aluminum foil.

Some aspects of manufacturing are unique to garments. A fire shield for a structure doesn’t need to be breathable—it shouldn’t be, in fact—and it need not be as nontoxic as a garment. But the fire shelters wildfire fighters carry with them are a different matter.

“Obviously you’re going to have a human being in there, and they heat up,” Hirning says. “So [the manufacturers] have to be very conscious of the gases that might be emitted from the glues and other materials that are used in construction. Because we’re protecting structures, we’re not held to those same requirements.”

The goal is the same, though, no matter what kinds of protective products companies are making: know your materials, know their limitations and find ways to keep improving the output.

TEXTILES.ORG

TEXTILES.ORG