As sustainability is increasingly important to growing numbers of consumers, fabric manufacturers are broadening their eco-friendly offerings, giving specialty fabricators plenty of green options.

As a famous frog once lamented, it’s not easy being green. The same can be said for companies wanting to “green” up their product offerings and manufacturing processes, since doing so typically requires no small amount of inventiveness and investment. And yet, more fabric manufacturers are doing exactly that, developing earth-friendly products intended to target sustainability-focused markets that grow ever more populous and diverse. Some of this innovation is driven by the need to stay competitive. But perhaps an equal if not stronger motivator is that for many fabric manufacturers, becoming as eco-friendly as possible just seems the right thing to do.

FRIENDLY FLEXIBILITY

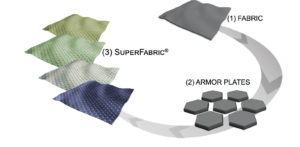

Consider Higher Dimension Materials Inc. (HDM). The company, headquartered in Oakdale, Minn., has developed more than 70 different versions of its SuperFabric® product. Essentially, this consists of imprinting tiny, epoxy resin armor-like plates in specific arrangements on a substrate fabric. The results—depending on the shape of the plates and their placement—are products that are extremely resistant to wear, abrasion, cuts, water and body fluids, as well as to stains and even needle punctures, says Richard Olmstead, Ph.D., HDM’s chief technology officer.

At the same time, because of the fabric substrate, SuperFabric remains flexible, conferring a versatility enabling it to be used by a variety of industries, ranging from automotive (the fabric was featured in an article introducing the Navara, the new Nissan concept car) to high fashion (models hit the runway wearing shoes made from SuperFabric) to the outdoor market (sports apparel, boots and shoes) to personal protection (cut-resistant gloves, arm guards and aprons, for example).

HDM obtains the base fabric (typically polyester, cotton, etc.) from a variety of vendors, many of whom are bluesign® and REACH certified, says Olmstead. The bluesign system seeks to make textile production more sustainable; REACH— which stands for Registration, Evaluation and Authorization and Restriction of Chemicals—is intended to better manage the risk of chemicals to humans and the environment. The resin plates are also chemically inert and won’t contaminate water once they enter the waste stream.

“SuperFabric lasts longer than traditional fabric, so apparel made from it lasts much longer,” says Olmstead. “Over time, less total material ends up in the waste stream. The stain-resistant qualities mean it requires less laundering, so less pollution results from the laundering process.”

HDM is introducing new forms of SuperFabric containing an antimicrobial agent that Olmstead expects will open up new applications, such as furniture upholstery for hospitals, nursing homes and clinics, where infections are a serious concern. The fabric incorporates silver zeolite compounds as the agent, rather than triclosan, implicated in the development of “superbugs” and recently banned by the government.

Olmstead says HDM’s primary purpose was providing a product with all of the aforementioned qualities while incorporating as many eco-friendly aspects into it as possible. “We not only strongly believe in the importance of offering eco-friendly products to our end users, but also understand the impact this has on our community and global citizens,” he adds.

UNLIKELY YARNS

Unifi Inc., headquartered in Greensboro, N.C., has taken steps to deal with the impact that discarded plastic bottles have on the environment. A diversified producer and processor of multifilament polyester and nylon textured yarns and related raw materials, Unifi also produces the REPREVE® brand, made of recycled materials like plastic bottles. So far, Unifi has transformed more than four billion post-consumer PET1 (polyethylene terephthalate) plastic bottles into REPREVE fiber, says Jay Hertwig, vice president of global brand sales, marketing and product development.

“The majority of REPREVE yarn is comprised of 100 percent recycled plastic bottles, but Unifi also produces REPREVE made from different combinations of recycled plastic bottles and manufacturing waste—pieces of fiber from polyester, nylon and traditional REPREVE—that break off during the manufacturing process,” says Hertwig.

With benefits like stretch, breathability, moisture absorption, wicking, durability and more, the REPREVE fiber—either on its own or in combination with other Unifi fabric brands or branded technologies—is used in apparel, hosiery and automotive products, and in some industrial applications. Leading brands utilizing the REPREVE yarn or yarn combinations include Patagonia, The North Face, Haggar, Volcom, Pottery Barn and Ford.

Spinnova Ltd., located in Vaajakoski, Finland, is a high-tech R&D company that works closely with the textile industry. Spinnova began operations in 2015, says Janne Poranen, CEO.

“So far, we’ve scaled our technology into small, pilot-scale production,” he says. “First potential end products are ready for upscaling. During the next 24 months, we’re scaling our production to small industrial scale. The main target of the next phase is showing that Spinnova yarns can be produced globally in industrial scale.”

The yarns Poranen is referencing are made directly from wood fiber (pulp) with no dissolution process, meaning that it’s not necessary to disintegrate the pulp fiber into polymers and then regenerate them back into filaments. Instead, thanks to Spinnova’s innovative technology, the pulp is sent through a specially designed wet spinning nozzle, which perfectly aligns the fibers with the flow, giving the yarn a good strength enhanced (as is stretch) through further twisting.

“The yarns are washable, fire retardant (without any chemicals) and antimicrobial,” Poranen says. “They can be made conductive and are naturally biodegradable. Yarn strength and stretch are comparable to cotton yarn. It can be produced in many different yarn counts, starting from 5 DTex staple fiber to thick 50 Tex monofilament-type yarns. And in production, Spinnova yarn can be mixed with any existing yarns to produce mixed fabrics.”

The objective is pointing the textile industry in a more sustainable direction, says Poranen, mentioning that Spinnova yarn production requires 99 percent less water, 80 percent less energy and 50 percent less land than does cotton production.

“Spinnova has calculated that just Finnish sustainable annual forest yield is enough to replace the entire global cotton production,” he says. “And, instead of virgin wood fibers, it’s also entirely possible to use other fiber sources, like recycled or plant-based fibers.”

OLD TO NEW

Ferrari North America.

Manufacturers are also exploring ways to put used fabrics to work rather than leaving them to loll about in landfills. Glen Raven Custom Fabrics, headquartered in Burlington, N.C., has been selling fabric for awnings since 1908, says Vince Hankins, industrial business manager for the company. In 1961, Glen Raven created the performance fabric category with the launching of Sunbrella®, used in numerous markets including upholstery, marine, contractandcommercial. Sunbrella products are popular because of their ability to withstand harsh conditions, like prolonged, direct sunlight and exposure to salt water while still maintaining appearance and high performance, says Hankins.

Included in the company’s Sunbrella offerings is the eco-friendly Renaissance collection that combines post-industrial and virgin fibers. There are several products within this collection: Heritage, an upholstery fabric; a line of rugs available through Colonial Mills Inc., and Unity, the company’s first Renaissance shade fabric.

“Because of the recycled content (50 percent post-industrial recycled Sunbrella fiber combined with virgin Sunbrella fiber), Unity fabrics have a vintage canvas look that is subtly textural and feels very substantial,” says Hankins. “As with all Sunbrella-branded products, Unity fabrics are GREENGUARD Children

and Schools certified as contributing to indoor air quality.”

Unity shade fabrics can be used for a variety of residential and commercial applications, including retractable and fixed awnings, umbrellas and other shade structures.

Serge Ferrari North America—a manufacturer of flexible composite membranes used globally by the marine, architectural, solar protection, building facade and furniture markets (among others)—is also focused on sustainability, energy control and the protection and renewal of natural resources. In 1996, the company began exploring how to recycle its materials intended for the print industry, says Elfriede Lynch-Willson, marketing and communications manager for the Pompano Beach, Fla., company.

“We saw this as an important step for this industry and for our commitment to be eco-friendly, where our materials are frequently used briefly for an event and then discarded,” she explains. “At the time, no one was recycling polyester/PVCs on a large scale, so Serge Ferrari began researching and developing its own technology.”

Devising the technology that would separate the components of flexible composite material into new, usable raw materials wasn’t easy, she says. But working in conjunction with another company, Solvay S.A., Serge Ferrari developed the process, dubbed Texyloop®, enabling it to open the Texyloop recycling plant in 2008 in Ferrara, Italy. The plant has a recycling capacity of four million square meters annually.

The process results in raw materials that are as good as the originals, affording 100 percent reuse of the recycled materials, says Lynch-Willson.

“To date, 9,646,000 square meters of cutoffs and end-of-life fabrics have been collected,” she says. “The raw materials from Texyloop are finding new purpose in items like membranes for water retention ponds, extruded rods for keders and nonwoven materials such as insulation. And in 2012, a fabric made with recycled polyester fibers was developed.”

MARKET DEMAND

Lynch-Willson says demand for Texyloop is strong in the print and tent markets, where there’s growing interest in recycling. “We sell them on the performance characteristics—strength, durability, hangs flat, etc.—then once they’re on board, we share with them the Texyloop process,” she says. “They don’t always know they want a recyclable product before we talk, but afterwards, it makes an impression.”

Architects and designers represent another opportunity. They’re usually interested in recycling, says Lynch- Willson, especially since many of their clients—such as those in hospitality or large corporations—have sustainability programs. “This gives them an additional selling point,” she explains.

Hertwig says that Unifi has been excited to discover that, increasingly, consumers expect businesses to be more environmentally conscious. “They’re demandinggreatertransparencywiththeir recycled products,” he says. “This has been a major driver for Unifi and will continue to be as the industry adapts to and drives sustainability trends.”

Account managers for SuperFabric report a “consistent increase in requests for eco-friendly fabrics,” says Jun Lee, vice president, marketing strategy and business development for HDM. Previously, the bulk of the interest came from their European clients, but now, they’re seeing more U.S. clients requesting green products, particularly the automotive, sports apparel and workwear sectors. She anticipates the interest in eco-friendly products continuing to grow globally, “making these materials a necessity.”

Hankins says the same, reporting that demand for their Unity shade products is on the upswing, mostly for commercial applications.

“I think the fact that almost every producer speaks to some environmentally friendly trait in their offerings indicates that an eco-friendly component is important,” he says. “And as awareness continues to grow and as the aesthetic appeal and performance of these products continues to elevate, they’ll become a bigger piece of everyone’s portfolio. If not, you’ll be left behind.”

Pamela Mills-Senn is a freelance writer based in Long Beach, Cali.

Since 2009, REPREVE has transformed more than 4 billion plastic bottles to make recycled fibers.

A BOTTLE-TO-FIBER PROCESS

Since 2009, REPREVE has transformed more than 4 billion plastic bottles to make recycled fibers.

Recycled plastic bottles are picked up curbside and taken to a materials recycling facility, where they’re baled and sent to the REPREVE Bottle Processing Center.

Recycled plastic bottles are picked up curbside and taken to a materials recycling facility, where they’re baled and sent to the REPREVE Bottle Processing Center.

They’re cleaned, sorted, chopped into flakes and taken to the REPREVE Recycling Center for further cleaning. Then they’re melted and reformulated into chips.

They’re cleaned, sorted, chopped into flakes and taken to the REPREVE Recycling Center for further cleaning. Then they’re melted and reformulated into chips.

The chips are melted and extruded into yarn, then sold to companies who knit or weave the yarn into fabrics.

The chips are melted and extruded into yarn, then sold to companies who knit or weave the yarn into fabrics.

BOTTLES BY THE NUMBERS

- 6 RECYCLED PLASTIC BOTTLES MAKE A SHIRT

- 50 RECYCLED PLASTIC BOTTLES MAKE A FLEECE JACKET

- FEWER THAN 32 PERCENT OF PLASTIC BOTTLES ARE RECYCLED IN THE U.S.

sample books, vinyl, sail hardware and other related materials, several Custom Marine Canvas employees have started side businesses, recycling the leftovers into duffle bags, totes, wine bags and tablet covers, keeping the

scraps out of landfills. Photo: Custom Marine Canvas.

Custom Marine Canvas, Noank, Conn., designs and builds dodgers, biminis and enclosures for sail and powerboats. The company also sells new sails and cleans, repairs and stores existing ones. They also design and manufacture full interiors, says owner Katie Bradford. Consequently, leftover canvas and other related materials is a business reality. But these don’t go to waste. Instead, some of her employees have created side businesses by turning these scraps, sample books, vinyl and sail hardware into duffle bags, totes, wine bags and tablet covers, primarily constructing these off-site in their own workrooms, although some are sewn onsite. The company doesn’t make any money from the bags; the biggest benefit is that the fabrics don’t get discarded.

Bags are also important to National Webbing Products, a manufacturer of narrow fabrics, located in Plainview, Long Island, N.Y. The company provides eco-friendly woven webbings in organic cotton, bamboo or recycled polyester to bag (and belt) manufacturers, as well as to pet leash and collar companies. Their primary business is private label, says Kathy Flynn, marketing manager.

“With our in-house design team, we work with our customers to develop the latest in new weaves, colors and finished styles,” says Flynn. “We’ve been offering eco-friendly webbing for almost 10 years. These items have helped to increase our sales in the natural products market.”

TEXTILES.ORG

TEXTILES.ORG