At each step along the supply chain, customers demand quality, efficiency, flexibility and speed. The right kind of equipment, with the right kind of software and the right kind of operator, can lead to long-term growth.

by Maura Keller

Today’s consumer expects faster turnaround times and custom quality at low prices, which means that manufacturers are also demanding the same kind of flexibility and service from suppliers—even faster. One challenging result of these increasing demands is that equipment suppliers are tasked with providing innovative, automated systems and value-added services that get the job done quickly and efficiently and keep customers’ customers coming back for more.

Mimaki USA Inc. has been on the leading edge of this trend for many years, working to create products and services that address production bottlenecks in cost-effective ways. As a worldwide manufacturer of printing and cutting devices, Mimaki makes a wide range of products to serve diverse markets, primarily for textiles and apparel, sign and graphics projects and industrial products.

“When it comes to textiles, there is an increased demand for both synthetic fiber and natural fiber,” says Ryosuke Nakayama, textile and apparel product manager at Mimaki USA, based in Suwanee, Ga. “Our textile customers are looking for consistency first and foremost. Each run must be able to be duplicated and match previous output.”

According to Nakayama, digital printing and automatization dramatically reduce labor costs and increase profitability. Mimaki develops products to address production concerns and increase consistency regardless of production facility or size. “One of these development projects is ‘Job Controller,’ which is part of our Internet of Things initiative. This approach enables customers to create custom products and produce in multiple facilities with reduced concerns,” Nakayama says. This “digital printing connection” software is intended to incorporate inkjet printers, formerly used alone, into production lines, for unattended on-demand production and mass customization using communication with peripheral equipment.

Managing workflow

According to Christina Lefebvre, area sales manager, North America, for Matic S.A., Matic’s equipment is changing based on customer requirements and industry requests. For example, Matic refines its cutters with new software features to improve a shop’s workflow and to manage fabric waste or inventory.

“For the welders, we improve by including more automated features, or by streamlining applications that previously took many steps to complete,” Lefebvre says. Matic, headquartered in Barcelona, Spain, manufactures cutting tables, welders, automated sewing systems and storage systems for the roller shade, awning and exterior screen markets (sun protection), and also manufactures equipment for the digital printing market. This year, Matic merged two of its existing welders into one new machine called the HERA. “This new model can now do all the functions of the two previous machines. It takes less space and is much faster,” Lefebvre explains. The HERA is a new generation of automatic impulse welding machine for hem pockets, overlaps, reinforced welds, zipper and keder.

At Autometrix Inc., Grass Valley, Calif., the size and performance of the company’s equipment is driven by the available materials its customers use and the size of the products they make out of that material.

“If anything, auto tables are getting bigger as more people use wider fabrics,” says Jonathan Palmer, CEO of Autometrix, which provides cutting solutions—CNC fabric cutters paired with software to make them easier to use and more productive. The company serves both the industrial textile and composites markets.

“We design our equipment for remote support. When people choose to start using automation in their manufacturing process, they quickly find themselves relying on it day in and day out—so we’re working to engineer a system that lets us diagnose issues and support them as quickly as possible,” Palmer says. Shrinking electronics and changes in motor drive technology have helped Autometrix achieve those goals.

Jeff Sponseller, chief marketing officer at Miller Weldmaster Corp., reports that tighter labor markets and the lack of the “seamstress” skill set drive demands for increased automation. “As such, we have started focusing our ‘design and build’ around easier-to-use machines with automation capabilities.”

Miller Weldmaster, Navarre, Ohio, creates thermoplastic hot air and hot wedge welding machines for the industrial fabrics industry. The company’s customers make a wide array of products, including awnings, ducting, tarps, inflatables, geomembrane liners, swimming pools, blinds, swimming pool covers and signs—essentially any type of product used outside that needs a watertight, clean and potentially airtight seam.

Innovative upgrades

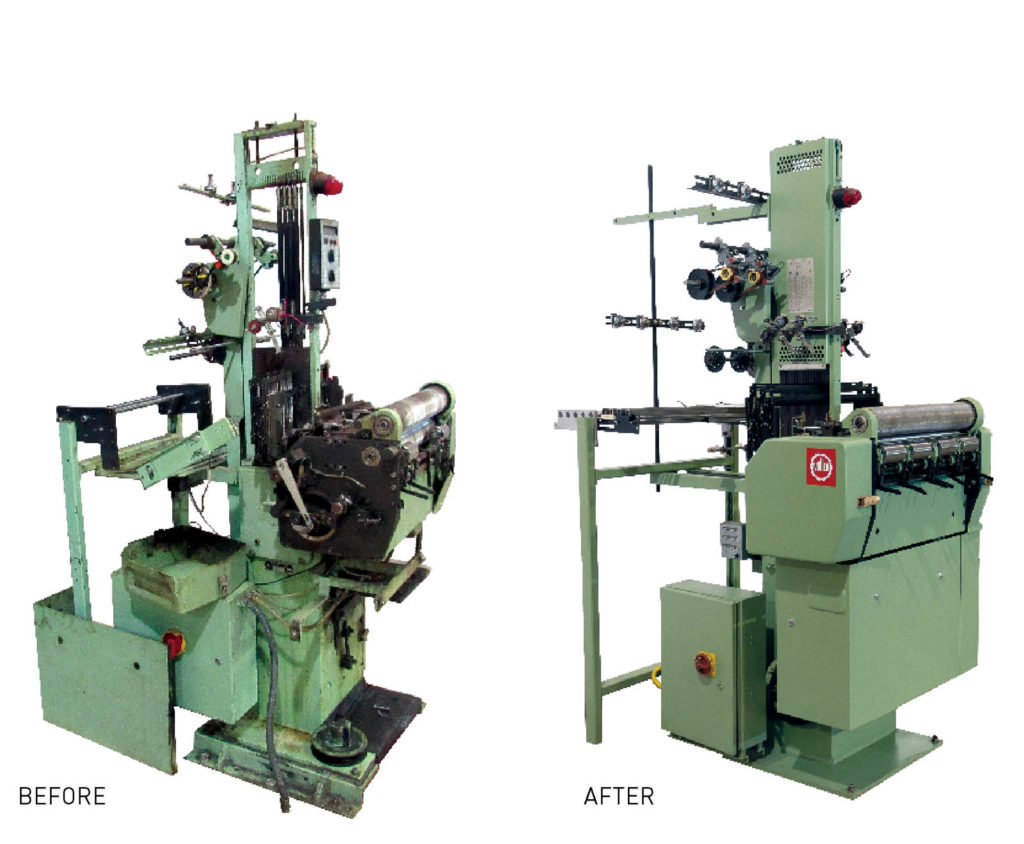

Many manufacturers in the specialty fabrics industry are highly innovative in their equipment upgrades—often working in conjunction with equipment suppliers. One notable example is Kamber Narrow Fabric Machinery LLC, a global trader in narrow fabric textile equipment that specializes in pre-owned weaving, braiding and knitting machinery.

As director of sales, North America, David Giltz explains, many companies in North America depend on Kamber to refurbish their narrow fabric needle looms—allowing them to get more years of use from the equipment and a better return from those significant capital investments.

Kamber’s latest innovation is its “Hot Swap” program. “We saw customers struggling when their Mueller Narrow Fabric Needle Looms were failing. They knew they needed to make repairs, but dreaded downtime. We realized our customers can’t do without their machines, any more than people can do without their cars. So we decided to do what car companies do: give them a ‘loaner,’” Giltz says.

With the new Hot Swap program, Kamber typically custom builds machines and ships them to customers, who lease that machine (or machines) that were built to their specific needs; only then will their existing machines be taken off-line for complete refurbishment and upgrades using OEM parts.

“If they have ten machines, for example, they might lease two machines from us,” Giltz says. “Once those are received and put into production, they send out two at a time to be refurbished and upgraded while our leased equipment keeps the company running smoothly. The complete and rebuilt machines are sent back, and the customer can keep going at full steam until all upgrades are done.”

Purchasing plus

According to Barbara Griffith, founder and president of SCL Equipment Finance in Tustin, Calif., in 2008, U.S. businesses invested $580 billion in equipment. By 2019, that figure had jumped to more than a trillion dollars.

“We see both leasing and buying, and each has its advantages,” Griffith says. “In some cases, you may not want to own the equipment, especially in an industry where using the latest technology is a must.”

In either case, most businesses opt for some form of monthly payment, rather than a lump-sum purchase. As Griffith explains, equipment produces income, just like an employee: It makes sense to pay for it over time, as it is earning money. A financing arrangement allows purchasers to conserve working capital.

“Really, it comes down to what deal works best for your particular business. What kinds of payments can your cash flow handle? What growth are you expecting?” Griffith says. “What changes do you see in the next five to ten years?”

But it’s no longer just a matter of financing terms. When purchasing equipment, many customers expect free software, training and repairs as well as favorable financing. While every customer situation is different, Lefebvre says what is requested often is free assistance once the machine gets installed. “They want Matic to be ready to answer any questions and offer help fast when they are faced with the challenges of learning to operate a new piece of equipment,” Lefebvre says.

And ROI? One of Kamber’s clients, VELCRO® Companies*, uses machines

of various ages, some newer and some older, for many of the products it manufactures. Besides routine maintenance and standard upkeep, a full refurbishment is scheduled at regular intervals to ensure optimal performance. “Outsourcing the refurbishment to a qualified company such as Kamber Narrow Fabric Machinery allows our maintenance team to focus more on the daily operations and routine maintenance to keep our operations more productive,” says Mike Tremblay, director of manufacturing services.

Tremblay estimates the company gained approximately 20 percent increased output on the first two machines refurbished by Kamber. “As Mr. Tremblay remarked, Velcro Companies also benefited from reduced downtime, repair time and parts as well as improved product output quality,” Giltz says.

At Autometrix, according to Jonathan Palmer, while used equipment is often asked about, when companies keep their paid-for cutters for 15 or more years, it means there’s a very limited number of used Autometrix machines out there—and they’re fairly old and accordingly hard to support.

At Miller Weldmaster, as the popularity of those machines has grown, so has the used market. While the company offers a small line of refurbished machines with full warranty for customers, those machines are relatively hard to come by.

“What’s most important to our customers is that when they purchase their machine, they get the investment of training as well. Most of our machines come with a full one-day training session that enables our customers to have it up and running quickly, and make product that same day,” Sponseller says.

A pathway to new markets

Purchasing new equipment often helps the end user go after new markets. In the past few years, Matic has seen a growth in the exterior screen market; some of Matic’s indoor roller shade customers are crossing over to the exterior market thanks to the versatility of the company’s new HERA welders.

“In the digital printing market, customers that typically printed only on PVC are tempted to start printing on fabric as well with our Cronos Sewing System,” Lefebvre says. “Finishing on fabric is always a headache that stops many customers from entering that market segment, but Matic makes it accessible because of our automation.” An automated conveyor-belt-driven solution for the production of silicone-edge graphics, flags, displays, banners, tents and curtains, the Cronos Sewing System can be built up with various options and attachments to suit various types of production and production budgets.

There’s another key concern: In a market that’s been built around customized production for one customer at a time, some fabricators question whether embracing automation will lessen their ability to provide customized products.

“Many people have an idea of automation that’s driven by factory automation—conveyor belts with robots doing the same task over and over,” says Lefebvre. “While there are industries, like marine canvas, that do require some special tools to account for how custom their work can be, many companies make custom sizes of similar products—like cushions, covers, awnings, etc.”

The right software tools are one way to blend customization and automation. Palmer recently visited an Autometrix customer who makes custom covers and has a library of thousands of patterns. That company has built a system that allows it to start with a base pattern and quickly adjust the details for a specific customer.

“They’re able to nest and cut in a matter of minutes because the majority of their pattern design is already done,” Palmer says. Autometrix provides industry-specific patterning tools, such as Eclipse for the awning industry and Pipes 3D for the insulation and inflatables industry. The company also provides templates, which allow customers to build a set of patterns once and then drive its dimensions with a few variable measurements.

“The time saved with this can be mind-blowing,” Palmer says. “Mix this with some order planning software that lets you customize what materials you want it made out of, and ‘custom products’ are actually profitable.”

Building efficiencies: people and profits

Sometimes, more automation can mean fewer employees. However, it can also mean cutting a night or weekend shift. According to Lefebvre, the main difference is in the speed of production—namely, that what took seven days to do can now take two days, with fewer staff.

“Ultimately your cost per product will go down, without touching your employee numbers,” Lefebvre says.

Palmer agrees, adding that most business owners want to grow, so the machine doesn’t replace an employee, but opens up that employee to do more valuable and productive work. An employee who formerly used hand-cutting tools will now also have the opportunity to learn how to run the new equipment and become familiar with advanced patterning software.

“Their job satisfaction goes up, and so does their productivity,” Palmer says. “Everyone truly wins when equipment is placed into a business with a healthy desire for growth.”

Partners in progress

The future of equipment automation seems especially promising for the specialty fabrics marketplace. For example, Autometrix plans to provide a more efficient flow between software and machines and back again. “We want to get rid of the tedious tasks where information can be lost or mistakes made,” Palmer says.

Miller Weldmaster plans on expanding operations in the market of the Internet of Things (IoT). “This will enable our customers to check in on their machine and understand what their production metrics might be per shift and even per employee,” Sponseller says. Also, IoT enables customers to connect via cell phones, to find out how one machine is functioning or what the operation uptime might be.

Smaller companies with a smaller amount of capital available for equipment purchases are naturally cautious when it comes to investing in new technologies, but it’s necessary to take a look at a company’s long-term goals and how to achieve them.

“At the end of the day, anyone can talk themselves out of spending a big chunk of money on something like a cutting machine, especially when they can keep cutting the way they are,” Palmer says. “We get that—but we also have a 30-year history of seeing companies take the leap and buy the right cutting solution, and we see how it changes the company.”

Griffith agrees. “It is so important to do what is right for your business now, rather than waiting. Besides the ROI that you can get in the future, it is important to consider what you are losing every month in your business right now if you don’t have the right equipment.”

Sidebar: How’s your ROI?

To determine the potential return on your investment, find answers to some critical questions:

- Can I cut staff if I buy this equipment? If so, how much will I save?

- Can I add staff if I buy this equipment, through increased efficiency?

- Can I increase production, and sell the additional goods produced? How much revenue can I expect from this?

- Can I attract new customers if my product is produced more consistently, more accurately and more economically?

Sidebar: Tax benefits: deductive reasoning

Section 179 of the IRS tax code allows businesses to deduct the full purchase price of qualifying equipment and/or software purchased or financed during the tax year. That means that if you buy (or lease) a piece of qualifying equipment, you may deduct the full purchase price from your gross income.

In previous years, businesses typically bought qualifying equipment and wrote it off a little at a time through depreciation. Section 179 now allows businesses to write off the entire purchase price of qualifying equipment for the current tax year—making it more financially attractive to purchase needed equipment right away.

*VELCRO® is a registered trademark of Velcro BVBA. Used with permission.

Maura Keller is a freelance writer based in Plymouth, Minn.

TEXTILES.ORG

TEXTILES.ORG