Sailors face all kinds of dangers during at-sea deployments. But improvements to a special suit—developed by Propel LLC with input from sailors themselves—promise to lessen one specific danger.

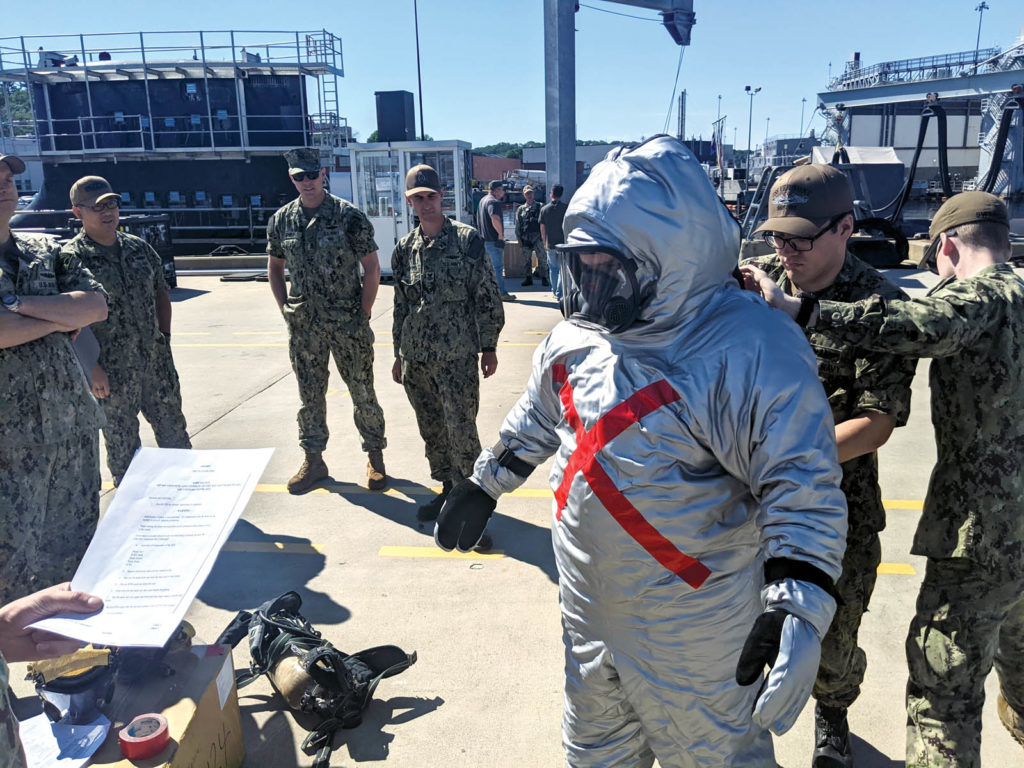

The Office of Naval Research (ONR) recently delivered new steam suits to crews of the USS Vermont and USS Indiana at Naval Submarine Base New London in Groton, Conn. The protective suits are worn when sailors need to make emergency repairs or rescue crewmates when a pressurized steam line has ruptured.

The suit has been in development for several years. While Pawtucket, R.I.-based Propel was working on a different project with the Navy Clothing and Textile Research Facility in 2014, technical managers inquired about a textile they saw in Propel’s facility—a fabric with a polyurethane polycarbonate coating on both sides. When tests showed that it was steam proof, Propel was awarded a Phase III Small Business Innovation Research (SBIR) research contract. The Navy provided a list of key performance parameters generated from user feedback for the suit. In particular, sailors wanted a lighter suit that could be donned quickly and fit anyone from 5 feet to 6 feet, 4 inches in height.

The previous steam suits were comprised of boots, firefighters’ coveralls, an air tank and breathing apparatus, and a hazmat-style chemical suit—all of which took about five minutes to put on. “The sailors were wearing what I would call cobbled together commercial items,” says Propel president Clare King. “It was heavy, bulky and difficult to move in.”

Propel reduced the weight of the suit from 22 to 11 pounds and cut donning time to under three minutes while maintaining protective strength and fitting the broad height range requested. Over the course of the project, Propel worked with Patagonia Inc., PrimaLoft Inc., Peckham Inc. (an AbilityOne Program that employs disabled people), Brookwood Co. Inc. and Tweave LLC at different stages of development.

ONR Command Master Chief Andrew Chupashko, who attended the suit delivery, noted that it was the first time in his 20-year career that he had seen a crew try out a technology with no complaints. King describes that kind of feedback as “amazing.”

“The contract is great, but the fact that it makes a difference in people’s lives is even better,” she says.

TEXTILES.ORG

TEXTILES.ORG