We are standing at an inflection point in world history. We can create an environment that raises the standard of living around the world,” President Joseph Biden said in his speech at COP26, the 2021 United Nations Climate Change Conference. “This is a moral imperative, and it is also an economic imperative.”

As world leaders came together in Glasgow to grapple with climate change, the textile industry gathered at IFAI Expo 2021 to consider how it is stepping up on the issue.

At Expo’s Advanced Textile Conference, a sustainability panel moderated by Apex Mills’ Stephanie Rodgers, included industry specialists and sustainability advocates Meredith Boyd, senior vice president of Technology, Innovation & Sustainability at Unifi Manufacturing; Lauren Choi, founder and CEO of The New Norm Fabric; and Ben Mead, managing director of Hohenstein Institute America. They represented a cross section of the speciality fabrics industry, contributing a brief overview of their own experiences before embarking on a wider discussion of the progress made by the industry, as well as the challenges ahead.

Action not words

While almost every advanced textile manufacturer now has established an environmental policy, it is the follow-through actions that matter in the end. Even the British monarch, Queen Elizabeth, was overheard expressing her frustration at those who “talk” but “don’t do” regarding climate change issues.

Each member of the panel set an example of the many ways that the industry is making a difference. Unifi, for example, is known for its focus on innovation and achieving a reduced environmental impact. In her presentation, Boyd demonstrated the company’s commitment to sustainability through their best-known product, Repreve®, a fiber made from recycled plastic bottles and used in applications from socks to automotive upholstery. According to the sustainability-focused Higg Index, Repreve offers a reduction in global warming potential by 21 percent compared with virgin polyester.

Choi was prompted to engage with sustainability when she realized two things: that although she readily recycled Solo plastic cups, she had no idea what happened to them after she put them in the recycling bin. Secondly, she learned how hard it was for a small business to source sustainable fibers and fabrics to the extent that “it was not really an option,” she said.

Choi’s company, The New Norm Fabric, began with a small extruder set up in her home garage to recycle the plastic cups into fabric. She was able to refine the process when she went back to the Johns Hopkins college campus where she was a student.

She sees consumers as both interested and engaged with sustainability, with their demand for greater transparency a positive influence on how both large and small businesses such as hers evolve.

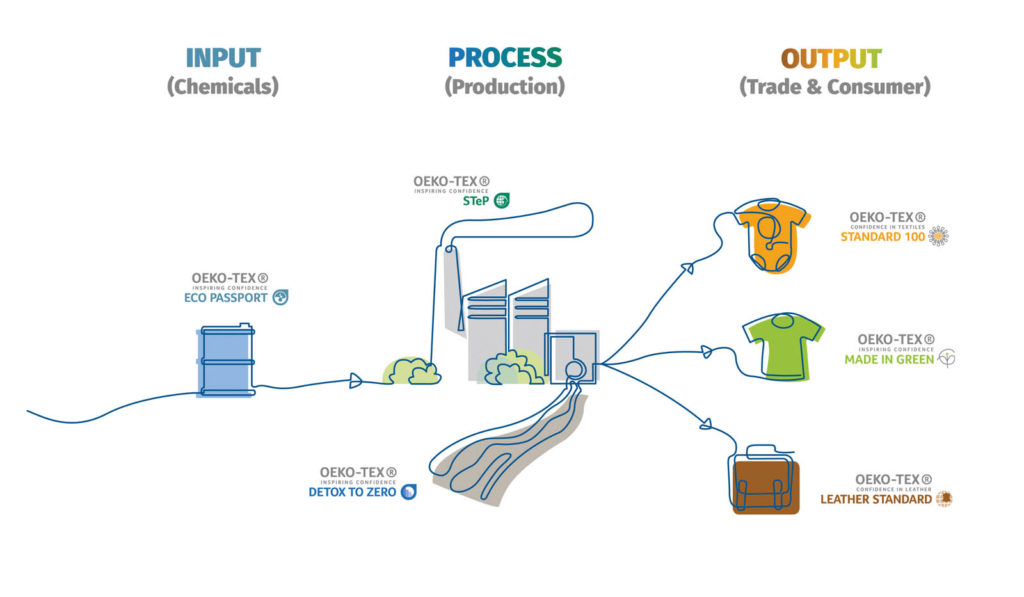

Hohenstein Institute America helps manufacturers address a broad spectrum of sustainability issues from testing and certification to finding ways to improve fiber shedding and product waste, says Mead. One of the most common questions that he receives is, “How do we get the measurable impact?” This in turn is driven by the consumer who is increasingly educated and wants to know about sustainability and the life cycle analysis of the product.

Designing for sustainability

Mead raised the issue of “designing for sustainability,” which needs to go beyond the label. “If we’re going to be serious about impacts, we have to get those products back in. No matter what they are, whether they be car seats or apparel or some sort of commercial textile,” he says.

“We are really designing those products to be able to have a future use,” which he acknowledged is a huge challenge. “How do we design to avoid contaminants in a use that we cannot envisage yet?” he asked.

One example of a dramatic market shift is the face mask. “A year ago, the idea that disposable face masks, gloves, and wipes could become global environmental pollutants was not a pressing concern,” Laura Palmer wrote in an article for National Geographic (“How to stop discarded face masks from polluting the planet,” April 14, 2021), “No one imagined just how much of it would be needed, for so long.”

Palmer estimates that 3 million face masks containing plastics that are not recyclable are used every minute with Asia alone estimated to discard 1.8 billion face masks daily.

Extended producer responsibility

Responding to an attendee question about how the panelists see themselves in terms of recycling responsibility, Boyd said she sees the responsibility at many points along the supply chain, but she also acknowledged that “unfortunately, sometimes things move really slowly if you wait for others.”

In fact, extended producer responsibilities (EPRs) and legislation can also be slow moving, in her view. At Unifi they have taken it upon themselves to create the demand and the capacity, but she agreed that the success of such initiatives is also dependent on other parts of the chain, and while markets may be global, local initiatives in addressing sustainability can differ considerably.

“I think that the brand and the retailer have an incredible opportunity to speak directly to the consumer,” she said. “I think in Europe the EPR will take more of a forefront position there.”

Accountability

Stephanie Rodgers, the panel moderator, raised another issue: “What about RFID tags or sensing technology?” She suggested that such technologies with their ability to harness, connect and disseminate data could be an invaluable sustainability tool. For example, this technology may be employed to help consumers simply know what to do.

Choi agreed that the consumer can and wants to be educated, but she sees such systems as incomplete. Apparel, in her opinion, is much more complicated to recycle than packaging, where tags are most often used for this purpose at present. While packaging can be PET, a garment might have several yarn types plus coatings or treatments. Choi does not believe that the technology is sufficiently developed to detect the multi-faceted textile and for this reason she sees other ways of sorting textiles as still needed. She suggests that RFID tags are useful as part of a broader approach and that the infrastructure for collection is crucial.

Decrease carbon emissions

At COP26, Sir David Attenborough was insistent that “we must fix our sights on keeping 1.5 degrees within reach,” which is a reference to the need to limit the global temperature increase to 1.5 degrees by the end of the century. To achieve this, he said, we need to stop carbon emissions this decade and recapture billions of tons of carbon from the air.

Ben Mead reminded the audience and fellow panelists at IFAI Expo that to achieve this as an industry, we need to reduce our carbon impact by 45 percent. This is a problem that has to be solved globally, and each step toward the goal matters.

Dr. Marie O’Mahony is an industry consultant, author and academic. She lives in Ireland.

TEXTILES.ORG

TEXTILES.ORG