Scientists at the Chinese University of Hong Kong (CUHK) have developed an edible and biodegradable material that may be an alternative to conventional plastic food packaging.

The material is made from bacterial cellulose (BC), a network of thin cellulose nanofibers synthesized by bacteria. Until now, the use of BC has been limited because of its sensitivity to humidity, which causes it to break down.

CUHK researchers were able to conquer this challenge by adding a bio-based composite coating to the material that allows it to remain stable in water.

The material was created by combining secreted cellulose from the bacterium Komagataeibacter xylinus, a sustainable, nontoxic bacterium, with soy protein isolated from soybeans. This bacterium is often fermented to make kombucha tea.

Unlike plastic packaging, the material completely degrades in one to two months, rather than hundreds of years. Neither does the process require industrial composting.

It is safe for humans and animals alike to consume, and because it is not made from plant cellulose, producing it doesn’t require harvesting crops or trees, eliminating the need to disrupt wildlife habitats. It also boasts a higher tensile strength than plant cellulose because of the integrated soy protein.

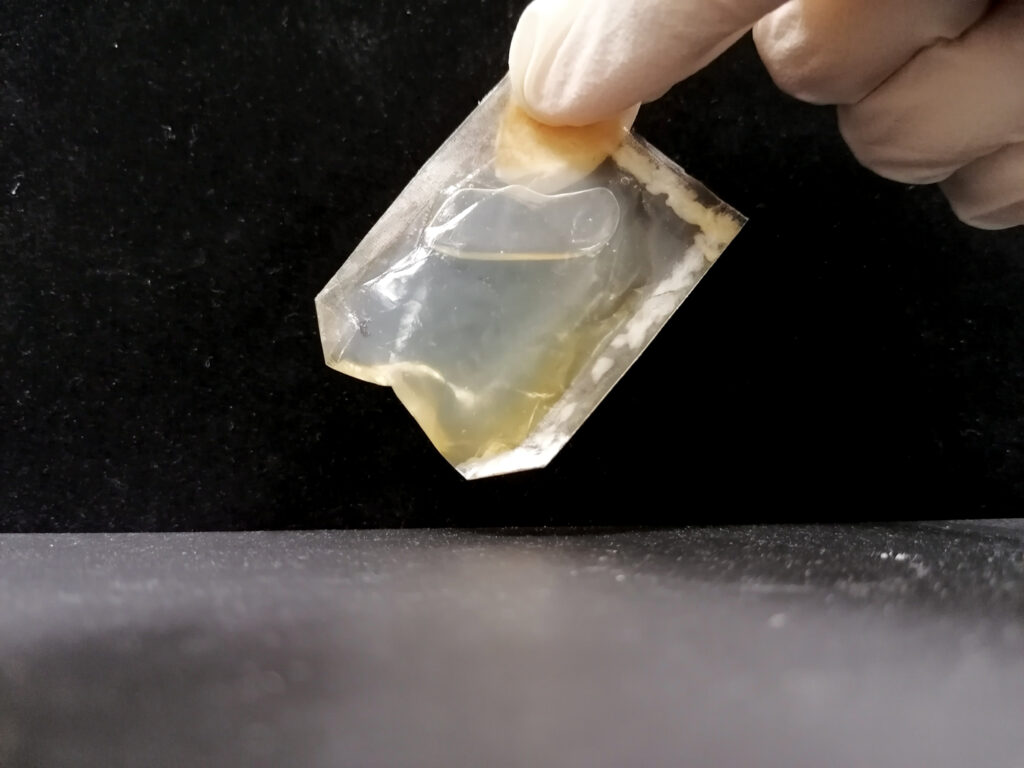

Researchers created single-use bags from the material which were suitable for storing bread, snacks, candy and similar foods. They also made drinking straws and found that they were more water-resistant than commercial paper straws, remaining intact after being immersed in both acidic and alkaline drinks for 24 hours.

“The material developed in this research is completely edible, making it safe for turtles and other sea animals to consume without causing aquatic toxicity in the ocean,” says To Ngai, professor in the department of chemistry.

The researchers’ next steps include developing a thermosetting glue that can create strong bonds between BC, allowing it to be easily molded into different shapes when heated, increasing its applicability.

This study was published in the Society of Chemical Industry’s Journal of the Science of Food and Agriculture

in June 2023.

TEXTILES.ORG

TEXTILES.ORG