Lithium mining requires large amounts of land and time to extract the salts from briny water, but a collaboration between Princeton University and University of Maryland researchers found that cellulose fibers could improve the process.

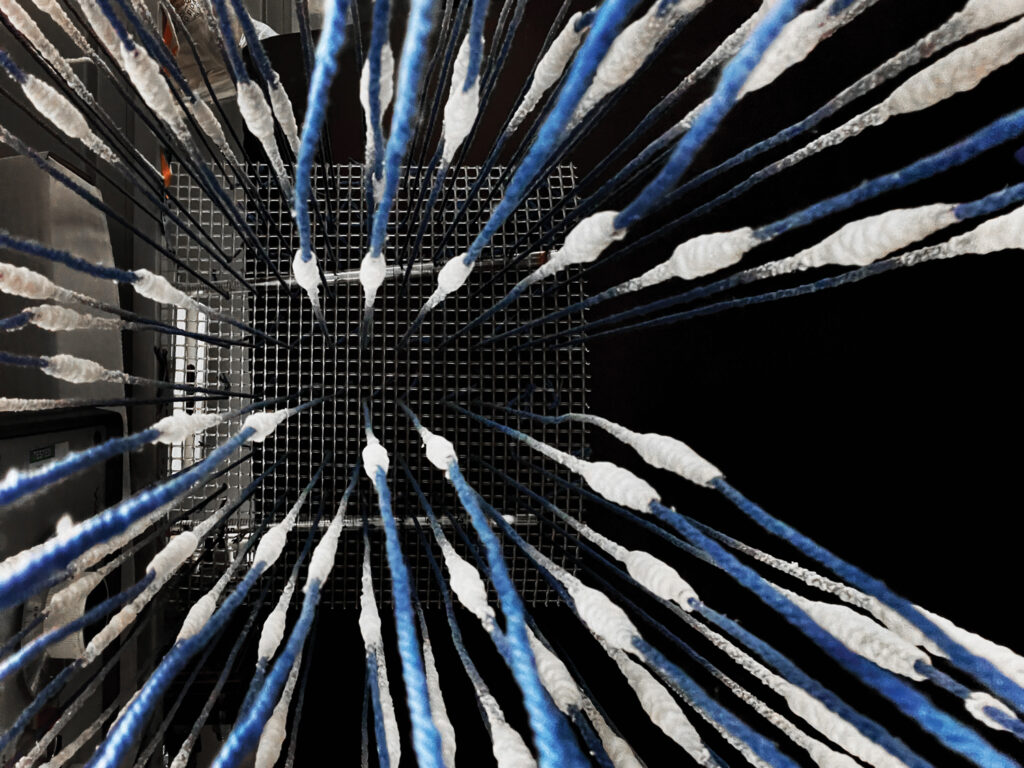

The engineers created strings that attract water to their core but repel water along the surface. When dipped in brine, the strings function like tree roots, using capillary action to draw water up into them. When the water evaporates, salts are left behind, such as sodium and lithium. The salts naturally separate themselves by type on different areas of the strings.

“We do not need to apply additional chemicals, as is the case with many other extraction technologies, and the process saves a lot of water compared to traditional evaporation approaches,” says Z. Jason Ren, professor of civil and environmental engineering and the leader of the research team. “Our approach is cheap, easy to operate and requires very little energy.”

The technique could improve production at existing facilities and make viable sources previously viewed as too small or diluted. Typical brine extraction involves huge evaporation ponds on sites measured in square miles, and time frames are from months to years. Commercially viable locations for lithium extraction exist in only a limited number of arid locations around the world where the material is most concentrated and enough land is available. Only one is currently operating in the United States, in Nevada.

Researchers have more work to do to scale up the process and are working on improving its efficiency and other factors. They estimate the technique can cut the land needed by 90% and accelerate evaporation by 20 times, potentially producing lithium harvests in less than a month. Disused oil and gas wells and geothermal brines could be investigated as new sources of lithium extraction as well as locations in more humid areas. Researchers are exploring whether even seawater could be a source of lithium.

The research was published September 7 in Nature Water.

TEXTILES.ORG

TEXTILES.ORG