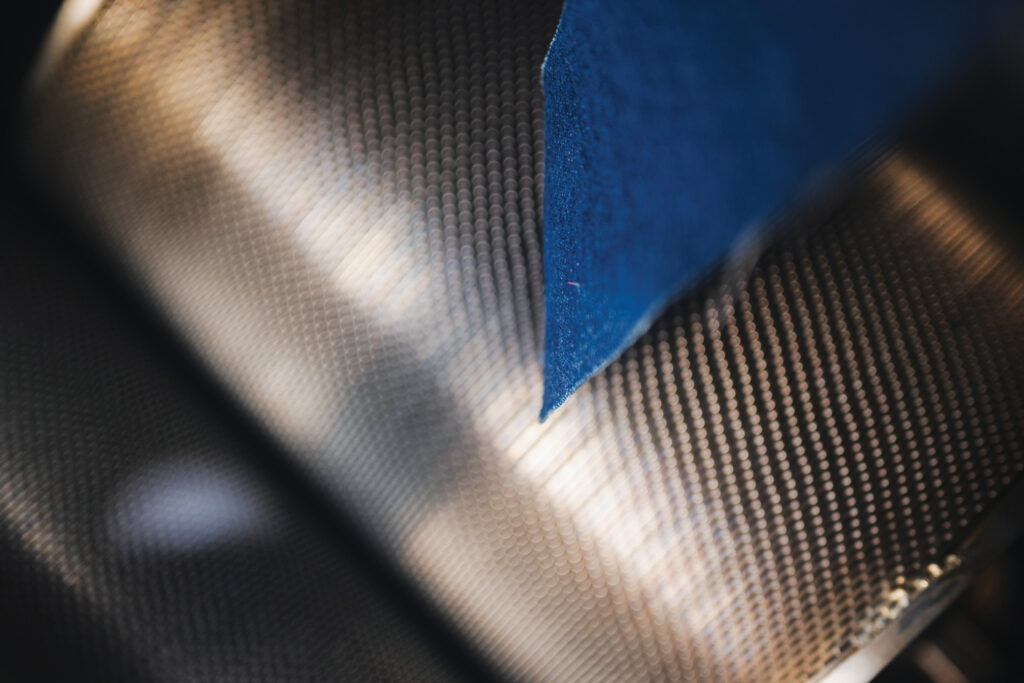

University of Minnesota Duluth associate professor Abbie Clarke-Sather, Ph.D., envisions a world where textile recycling is commonplace. Where thrift stores, recycling facilities and clothing brands can manage their own textile waste, turning it back into fibers that can be reused instead of going to landfills by the literal millions of tons. She and her team have been developing the Fiber Shredder for the past six years. It’s a little bit of a misnomer, as the machine pulls apart textiles rather than cutting them, leaving the fibers longer and more usable for re-spinning. It does the job in about 90 seconds.

She and her team have been working with True North Goodwill, which operates 11 retail stores and donation centers across northern Minnesota and Wisconsin. For materials that are too worn or otherwise unsaleable at the retail stores, the organization works with salvage customers who buy materials by the pound. True North Goodwill moves 2.2 million pounds of unsaleable textiles every fiscal year. Even after that, there are still leftovers.

The Duluth research team in Clarke-Sather’s lab is working on scaling up the Fiber Shredder prototype for commercial production. The aim is to have the industrial-scale machine installed in late 2025 at the new True North Goodwill building where it can be part of a material sorting line and preprocessing area. But the biggest problem the team will be working on is not the equipment. “The greatest problem is differences in material types and mixing those materials together,” says Clarke-Sather. “There aren’t very many buyers interested in fibers that are an unknown mix or unknown percentage mix of materials.”

She welcomes collaboration with others in the industry and partnering with chemical recyclers with the ability to separate mixed fibers. Even though the problem is global, it starts regionally. “I’d love us to be able to make a regional movement for recycling textiles so we don’t have to transport textile waste across the world for reuse, sorting and recycling,” she says.

Clarke-Sather is an associate professor of mechanical and industrial engineering at University of Minnesota Duluth and has worked in civil and environmental engineering as well as fashion and apparel studies.

TEXTILES.ORG

TEXTILES.ORG