While the topic of soft robotics is primarily exclusive to the academic and research world, it is still targeted at specific markets and applications. From the medical field and agriculture to search and rescue missions, soft robots may offer a solution.

What is a soft robot?

Multiple definitions of soft robots exist, according to Andrew Sabelhaus, Ph.D., an assistant professor at Boston University and director of the school’s Soft Robotics Control Lab. Sabelhaus says that although the research community disagrees over what defines a machine as “robotic” and what constitutes something as “soft,” a common definition is “the use of nontraditional materials within parts of the robot that contact its surroundings.”

Edoardo Milana, Ph.D., is head of the Laboratory for Soft Machines at the Department of Microsystems Engineering, University of Freiburg, Germany. He describes soft robots as those machines that, unlike traditional industrial robots, “achieve motion through deformation of their continuous monolithic bodies rather than through the rotation or translation of rigid links.”

This means that while traditional robots typically consist of multiple rigid parts or links connected by joints, a soft robot is usually designed with a singular flexible material. Whereas a traditional robot moves by either rotating or sliding separate parts, a soft robot’s movements are achieved by bending, flexing, twisting, etc.

Milana’s first encounter with the field of soft robotics occurred around 10 years ago during his master’s thesis research at the University of Leuven in Belgium.

“The project involved developing and integrating stretchable strain sensors into soft bending actuators to enable feedback control,” he says. “What captured my interest was the radical paradigm shift in how these machines are built.”

Sabelhaus has been exploring soft robotics in his postdoctoral research since 2019, when he joined the Soft Machines Lab at Carnegie Mellon University. Before he arrived at Carnegie Mellon, he had been working with NASA on flexible walking robots, where he experienced various obstacles in his research.

“Small errors or imperfections would easily cause the robot to tip over while attempting to walk, causing it to fail at its task,” says Sabelhaus. “I had been following the new trend of soft robots for a while and was fascinated by the possibility of combining soft materials into robots to prevent these difficult-to-resolve practical problems.”

Real-world applications

The materials used in these machines—such as silicone rubbers, thermoplastic elastomers, gels or various complex fluids—provide the softness, but the device’s structure also can be designed to allow soft behavior, Milana explains.

“For instance, thin foils, flexural hinges, springs or textiles can be arranged in ways that induce compliance, even if the materials themselves are quite stiff,” he says. “Thus, softness in robotics can stem from both material properties and mechanical architecture.”

Although most research into soft robotics is in academia, industries are exploring various ways to use soft robots. For example, in the medical field, soft grippers are designed to handle fragile and/or irregularly shaped objects, such as medical instruments, with precision. Rehabilitation and assistive devices also utilize soft mechanisms in wearable robots to improve safety and comfort, says Milana.

Researchers at Johns Hopkins University have developed a prosthetic hand that can grip various objects and adjust its grasp to avoid damaging them. The hand combines the advantages of rigid and soft robotics to create “a more natural prosthetic that functions and feels like a lost limb,” says Sriramana Sankar, a Johns Hopkins doctoral candidate in biomedical engineering who led the work.

The system features three layers of tactile sensors in the finger joints, inspired by layers of human skin. The layers allow the hand to grasp and distinguish objects of various shapes, sizes and textures, rather than merely detecting touch. The finger joints are air-filled and controlled by the forearm’s muscles. Using machine learning, the information from the fingers’ sensors is translated into a realistic sense of touch through electrical nerve stimulation.

During testing, the hand identified and manipulated 15 everyday objects, from plush toys, cardboard boxes and sponges to metal water bottles and pineapples. It successfully handled the objects with more than 99% accuracy, adjusting its grip as needed to prevent damage.

“This hybrid dexterity isn’t just essential for next-generation prostheses,” says Nitish Thakor, Ph.D., a biomedical engineering professor at Johns Hopkins who directed the study. “It’s what the robotic hands of the future need because they won’t just be handling large, heavy objects. They’ll need to work with delicate materials such as glass, fabric or soft toys. That’s why a hybrid robot, designed like the human hand, is so valuable—it combines soft and rigid structures, just like our skin, tissue and bones.”

Walking and jumping soft robots are also being studied to explore their potential to navigate various terrains for aiding in search and rescue missions. Researchers at Georgia Tech created several 5-inch soft robots that can jump up to 10 feet high. Inspired by the movement of nematodes—parasitic worms—the robots have a silicone rod with a carbon-fiber spine and can jump in multiple directions at various heights. To jump, the robot points its head straight, creating a kink at the opposite end of its body and catapulting it upward. The researchers found that the kinks were the key to the robot’s acceleration, as they could hold energy and rapidly release it. The study could lead to the development of other flexible systems made of carbon fiber.

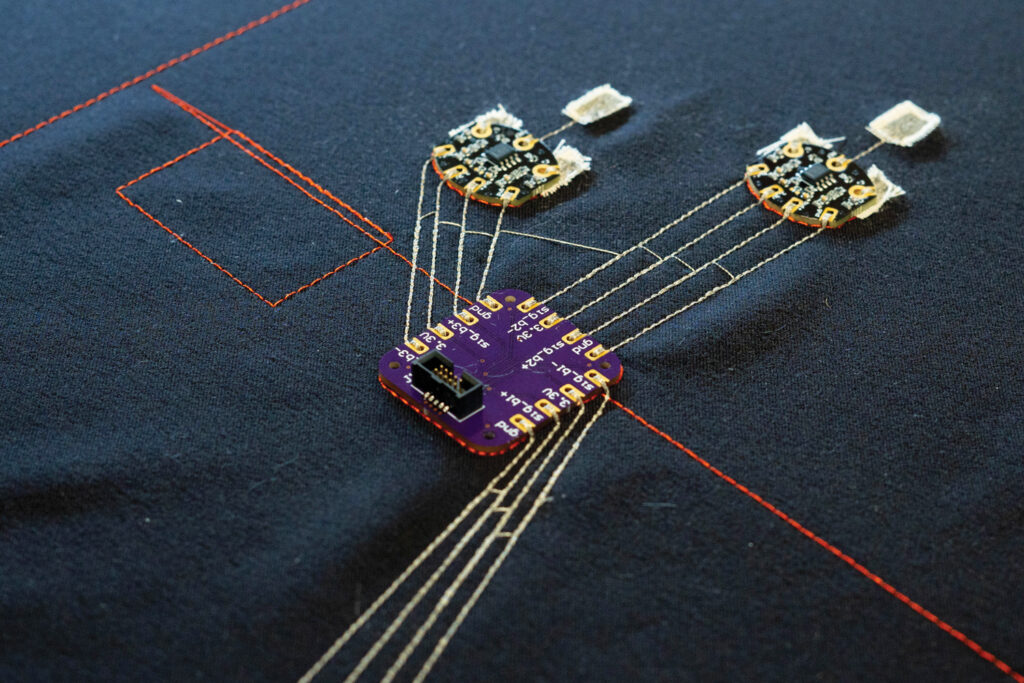

While traditional materials used in soft robotics are rubbers or silicones, fabrics and other textiles are being incorporated, says Sabelhaus, explaining that the most common role the fabrics play is serving as the exterior of a device that has a flexible interior, such as one composed of foam containing spaces for “tendons” to run throughout. “Think human hand with muscles and skin,” says Sabelhaus.

“Soft robots are excellent candidates for any machine that interacts with a sensitive environment in a setting that is difficult to measure precisely,” he adds. “Situations in which humans need to use our subjective judgement or rely on our sense of touch are some of the best uses.”

Sabelhaus believes agriculture represents a good opportunity for these devices. For example, soft, flexible grippers could be deployed to pick delicate fruits and vegetables far more efficiently and with less damage than rigid robots. They could also be used to help farmers and horticulturists deal with environmental stressors, such as droughts. Researchers at Cornell University developed a soft robotic gripper that can inject plant leaves with sensors that monitor the plant’s health and biological visual reporters that identify genetic transformations within the plant.

The gripper delivers two types of probes, including AquaDust and RUBY. AquaDust is a gel particle that lights up in response to the leaves’ water levels and is used to monitor a plant’s hydration. RUBY is a gene-encoded visual reporter that causes red pigmentation to appear where genetic transformations occur within the plant.

Researchers tested the hands-free system on the leaves of two plants known for their structural resistance to infiltration—sunflower and cotton leaves. The researchers found that the device caused significantly less damage than syringe-based methods and had a successful delivery rate of 91%.

The team is now working to integrate the gripper onto robotic arms for automated greenhouse systems. This research could lead to the development of other smart agriculture and plant research devices. Based on the study’s results, the gripper could also be used in the future to bioengineer plants.

“Soft robots can be made from anything and everything that deforms upon contact,” Sabelhaus says. “My personal favorite soft robot with an unusual material is a crawling robot made from pine cones. By alternatively making the robot’s pine cone legs wet and dry, the legs flex in and out, creating a walking motion. It’s a testament to the versatility of

the idea of soft robots.”

Promising solutions

Milana describes soft robotics research as “rapidly advancing in many exciting directions.” As such, he believes these devices will play an integral role in the development and design of robotic systems in the future, particularly in the integration of hard and soft elements.

“For example, humanoid robots may incorporate soft hands to enable compliant gripping and tactile sensing and joints with variable stiffness to improve energy efficiency and adaptability to external forces,” he says.

“Soft actuators, as artificial muscles, could eventually replace traditional servomotors, reducing weight, simplifying mechanical transmission and lowering the computational demands of motion control,” Milana continues. “These advancements could make robots safer, more adaptable and better suited to dynamic, real-world environments.”

Currently, his lab is investigating how to integrate soft sensors into robotic systems that would allow a robot to sense both its position and movement as well as the external environment, Milana says.

Sabelhaus says his lab’s primary goal centers around soft-robot safety, working to develop a theory of what “safe” really means and translating this “informal understanding” from words into an engineering specification. And just as definitions vary on what constitutes a soft robot, the concept of safety is debated within the research community. His research lab is looking at safety in three ways:

- Forces/force limits: Are they too high or too low?

- Contact: How to prevent this from occurring in the wrong place

- Degradation: When the robot breaks down or its performance degrades

“We hypothesize that the calculations of how a soft robot should move and when could be determined mathematically by optimizing for the safest motion possible,” he explains. “What forces on a person are safe versus not? How does a robot identify when it’s impossible to perform a motion safely?”

Basic proof-of-concept ideas for the lab’s soft robot have been established, allowing it, for example, to recognize when it is exerting too much force and ensuring its force remains within safe limits. The robot can also detect when some of its parts have accidentally disconnected. But in terms of being able to perform tasks safely in a home health care environment, there is “much more work to be done.” In the future, Sabelhaus hopes soft robots can provide autonomous health care.

Although soft robots offer promising solutions to many challenging problems, Sabelhaus says they have yet to find the right combination of “business case and robust technology,” resulting in a dearth, so far, of industrial partners willing and capable of manufacturing these devices at scale. While soft materials can prove less expensive compared to rigid ones, development costs would be prohibitive, making consumer purchasing unlikely. This is why researchers feel that, for now, the most promising path to profitability is selling to manufacturers, mirroring an industrial business model similar to that of factory robots.

Pamela Mills-Senn is a freelance writer based in Seal Beach, Calif.

Megan Phillips is the associate editor of Specialty Fabrics Review. She can be reached at Megan.Phillips@textiles.org.

SIDEBAR: Propelling Textile Innovations

Since its founding in 2016, Advanced Functional Fabrics of America (AFFOA) has focused on propelling the textile industry forward by developing and scaling advanced technologies in fibers and fabrics. Smart textiles are of particular interest, says Michael Rein, director of engineering for the Cambridge, Mass.-based nonprofit organization.

Rein says that as a Manufacturing Innovation Institute, AFFOA is well-positioned to facilitate advancements in smart textiles, merging electronics with traditional textile materials. As such, it is capable of devising materials that can, for example, heat and cool, capture and generate energy, and provide biometric readings and various types of data.

“There is a great deal of interest in smart textiles, with more research being conducted to determine the best applications for these technologies. In particular, research is being done combining textiles and robotics and human/machine interfaces that would involve textiles,” says Rein, who believes smart textiles have applications in soft robotics and sees the potential for interplay between the two.

AFFOA conducts its own research but primarily works with its 143 member organizations to develop their technologies, Rein says. Membership organizations are from across the textile industry and include academia, startups, commercial brands and defense prime contractors.

Three components support AFFOA’s mission, says Rein. These are:

- Technology maturation and manufacturing processing development

- Education and workforce development

- Ecosystems development

“It’s important for manufacturers to grow and advance their businesses in order to remain competitive,” Rein says. “Being aware of the new technology that is being produced and being able to produce this in the U.S. is essential. AFFOA puts manufacturers in touch with new ideas, markets, technologies and applications, giving them visibility and knowledge.”

TEXTILES.ORG

TEXTILES.ORG