We wear textiles for protection from the elements—walking in the rain, shielding ourselves from the sun, or even removing dinner from the oven. It’s interesting to consider what goes into making these everyday textiles, but it’s also interesting to consider how they are made. What are the steps needed to make more robust protective textile applications, such as gloves for utility work, scrubs in a medical setting or a garment for space exploration?

Protective, functional textiles must always be reevaluated to maintain human comfort preferences and industry requirements. For the specific case of military uniforms, a more serious application, the intention is to protect soldiers from the weather but also from more life-threatening elements such as chemical, biological, radiological and nuclear threats. With a more diverse population serving in today’s military, as well as preferences voiced from soldiers themselves, a more form-fitting, yet nonrestrictive, garment has been requested for use in daily uniforms.

Meeting the requirements

The next generation of duty uniforms for soldier performance must be highly stretchable, robust and flame retardant and have superior moisture management properties. Under a National Science Foundation (NSF) Small Business Technology Transfer (STTR) Phase I contract, auxetic textiles that integrate these performance attributes have been developed. An auxetic material is one with a negative Poisson’s ratio that becomes thicker when stretched and becomes narrower when compressed. Auxetic materials—in particular, fabric—can provide increased impact resistance and sound-dampening properties, among other benefits.

The research group consisted of team members from Advanced Cooling Technologies, represented by Srujan Rokkam, Ph.D., and Kuan-Lin Lee, Ph.D., who are professionals in thermal management, and North Carolina State University Wilson College of Textiles researchers Andre West, Ph.D., Kun Luan, Ph.D., and Zoe Newman, Ph.D., who are focused on auxetic textiles.

The goal was to develop a textile with the durability of a woven fabric and the stretch and breathability of a knitted fabric, while retaining certain requirements set by the U.S. Army. Such requirements included, but were not limited to, breathability,

flame resistance and burst strength. The fabric development, funded by the STTR and Small Business Innovation Research (SBIR) programs, followed extensive yarn research and fabric performance tests.

Balancing factors

The task of developing a textile with the stretch of a knit fabric and the durability of a woven fabric inherently requires expertise in yarn and knit structures, as many knit fabrics are not as durable as woven fabrics, in which yarns are interlaced (not looped) among one another.

First, a yarn material trade study was conducted to determine which yarns met U.S. Army standards. All yarns were produced in the U.S. and had some element of protection, such as fire retardancy and moisture management. The yarns used in the selected fabric included a modacrylic blend and Nomex®, based on their individual predetermined performance. Both fibers present inherently flame-resistant properties, ideal for fabric development in this realm.

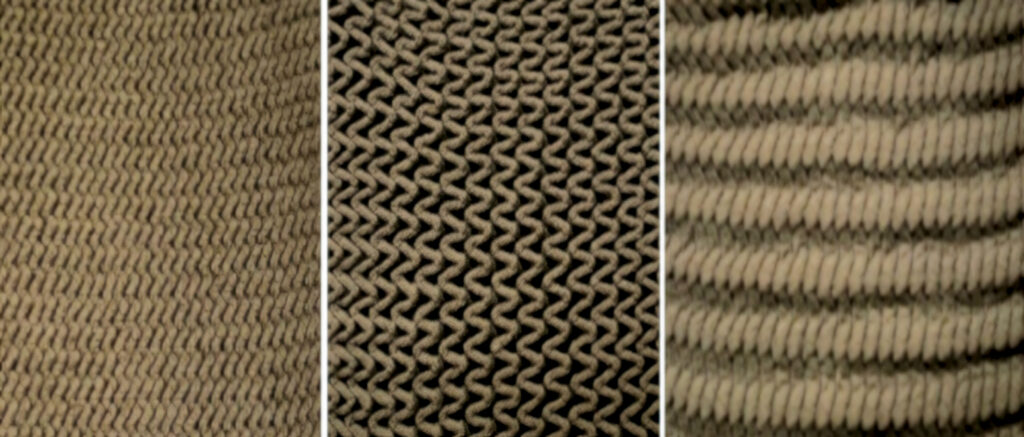

The property of knit fabrics can vary greatly based on design for end use. The approved, tested yarns were not very extensible—a good quality of strength—but there was difficulty, in many cases, in knitting on an electronic flatbed knitting machine. Therefore, the research team needed to consider various knit structures to develop the desired stretch in the fabric. The technique of links-links knitting was explored using a Shima Seiki SIR123 18-gauge knitting machine, one of the most popular flatbed knitting gauges for developing garments in the knitting industry.

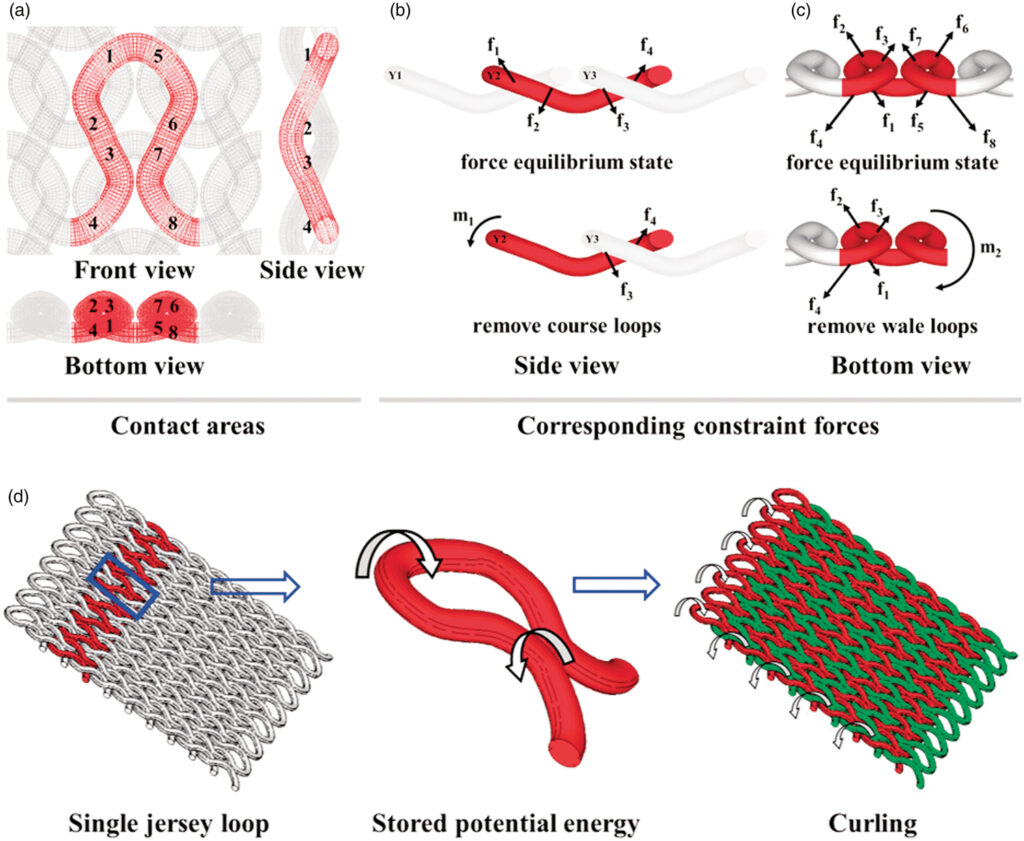

Links-links knitting is a technique in which the two beds of a flatbed knitting machine are used to create opposing knitting zones, resulting in a self-folding effect. The curling of the fabric knit on the opposite needle bed opposes one another. If such structures are placed properly, the fabric can be auxetic.

The application of the auxetic textile may be most beneficial in areas of high movement on the body, such as the shoulders, elbows or knees, due to its extensibility. However, to understand where the fabric may be placed, it was important to understand the physical properties of the developed fabric.

Comfort and performance

The fabrics were tested for flame retardancy, moisture management, isotropy and other parameters. Nearly all test results met or exceeded the project requirements. An added consideration in the development of the fabric, with respect to placement on the body, was the concept of moisture wicking. In this case, the auxetic structure was modified to include a plating yarn on one face of the fabric, resulting in area-specific hydrophilicity to enhance moisture management, thus creating two different functional faces.

Through the understanding of the physical properties of the fabric—including but not limited to isotropy, moisture management and weight—three different Army combat uniforms were conceptualized in which auxetic placement would be on the shoulders or in the yoke area. Such concepts are not available for public release; however, the integration of auxetic fabrics into such robust garments is promising for developments in protecting those who serve their country.

Conceptualizing the future

In considering the use of auxetics in the future, efficacy at different scales is important; one cannot place a large-scale fabric on a small area and expect the same impact resistance results as from a small-scale fabric in the same area—an important consideration for high-performance military applications on the body. Further, additional research should be conducted on the impact of yarn size and content as it affects the isotropy of a knit structure.

The task of developing a fabric with a knit-like stretch and woven-like durability challenged the team to home in on their expertise to produce a suitable solution for this Army project, while contributing to the future of novel textiles and soldiers’ well-being.

Zoe Newman, Ph.D., is currently a knit product developer working at Stoll by Karl Mayer in Greensboro, N.C. She enjoys contributing to the development of functional textiles and helping others learn about knit fabrics and knit programming.

This research was funded by the U.S. Army under Small Business Technology Transfer (STTR) awarded to Advanced Cooling Technologies Inc. (ACT), in collaboration with North Carolina State University, via contract number W9110Y21P0012. Approved for public release per PR2023_88532.

TEXTILES.ORG

TEXTILES.ORG