The medical and military industries are both in need of fabrics that offer protection against biological threats in health care environments and, for warfighters, the threat posed by chemical warfare. The challenges faced are complex; protection against multiple agents could be needed, and the agents may even be unknown.

Against such obstacles, the development process for chemical, fiber and fabric technologies needs to incorporate flexibility to allow for change when new challenges emerge—as they most certainly will.

Toxic nerve agents

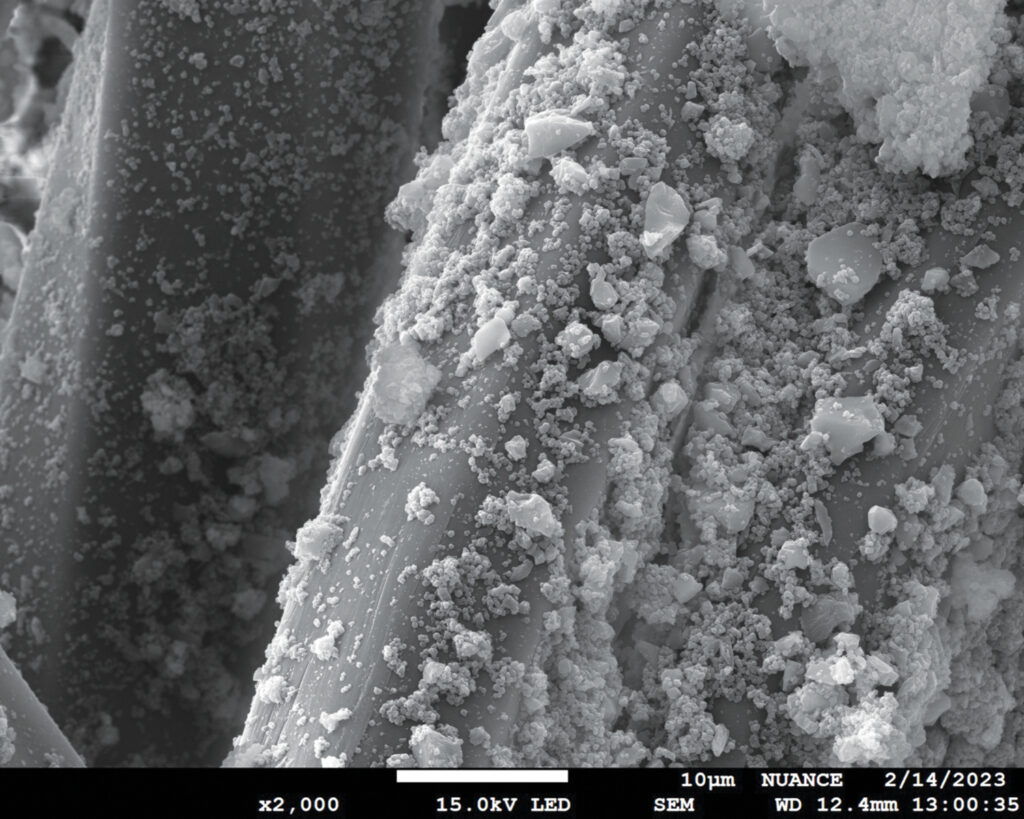

Omar Farha, Ph.D., is a professor and expert in metal-organic frameworks (MOFs) at Northwestern University. Farha and his Northwestern colleagues have worked with Hong Kong Polytechnic University to build on an earlier study of Farha’s that examined nanomaterials and their ability to deactivate toxic nerve agents. Now, they are working to develop a regenerative and multifunctional N-chlorine-based biocidal and detoxifying textile using a zirconium MOF.

The material is like a sophisticated bath sponge, housing a complex series of holes that capture gases, vapors and other agents like a sponge traps and holds water. The cavities in the MOF contain catalysts that deactivate the toxic chemicals, viruses and bacteria.

“Having a bifunctional material that can deactivate both chemical and biological toxic agents is crucial since the complexity [needed] to integrate multiple materials to do the job is high,” Farha says.

In this new development, the researchers found that the MOF/fiber composite responds quickly to exposure to SARS-CoV-2 and both gram-negative bacteria (E. coli) and gram-positive bacteria (S. aureus). A chlorine-loaded MOF/fiber was shown to cause rapid degradation to sulfur mustard gas and 2-chloroethyl ethyl sulfide, which acts as its chemical stimulant.

Important for long periods of use, the nanopores of the MOF when coated on textiles allow the material to be breathable. Used as a face mask, for instance, it would allow protection to the wearer from virus exposure as well as protection for others when worn by an infected person.

The permeability problem

Rahman Bhuiyan, Ph.D., and colleagues at the Royal Melbourne Institute of Technology and the Australian Department of Defense have undertaken research into chemical protective clothing (CPC) and textiles, highlighting advances as well as issues that still must be overcome. One persistent problem is permeability.

While impermeable coatings and laminates such as polyethylene and polyvinylidene chloride can provide effective barriers against chemical liquids, vapors and aerosols, their lack of breathability can cause the buildup of body heat, which can lead to heat stress. Well-designed CPC suits need to balance performance with comfort so that a single suit can demand multiple functionalities from the textiles, including permeability, impermeability, semipermeability and air permeability.

The selectively permeable membrane (SPM) is designed to allow the permeation of water molecules but not organic molecules. The SPM works by a process of continuous evaporative cooling that lowers the body temperature, reducing heat stress while protecting against toxic chemicals.

An example of the advances in CPC suits is the U.S. military’s Joint Services Lightweight Integrated Suit Technology. This is an overgarment designed to protect active service personnel from chemical and biological agents. Lighter and less bulky than previous garments, it can provide 24 hours of protection against chemical liquid and vapor attacks, is durable for 45 days, and can be laundered up to six times.

Arguably, as dangerous as the things that we know about chemical protection are, the things we think we know can be just as dangerous. Materials that we know offer great protection in one area may offer little in others. In Joe Geng’s book Rethinking Hand Safety, published by his company Superior Gloves, he writes that leather is great for many kinds of work gloves, but for chemical protection, it is “nearly as porous as human skin to dangerous chemicals.”

Dangerous chemicals can soak through aramids, for example, but aramids provide excellent protection against cuts. The needs of the worker are often multiple as is evident by many of the descriptions on Superior Gloves’ website: coated gloves for dry chemical protection and secure grip, chemical-resistant gloves with nitrile palm coating for wet grip and nitrile gloves with ceramic powder grip finish for wet and oily conditions.

Geng describes winter protection as particularly challenging, with people often needing multiple layers to stay warm but also needing moisture management. Additionally, other requirements are needed, such as cut resistance, dexterity and launderability.

Vapor hazards

Not all chemical dangers are visible to the human eye. Researchers at North Carolina State University are using a Man-in-Simulant-Test (MIST) to assess the effectiveness of textiles against chemical vapor hazards. Tests are performed with human subjects undertaking moderate exercise while wearing the garment to be tested with adsorptive patches placed directly onto the skin. A controlled concentrate of the nontoxic methyl salicylate, also referred to as the oil of wintergreen, is used as the chemical vapor in MIST.

The facility is the only one of its kind in the United States and is in the university’s Textile Protection and Comfort Center for use in testing protective apparel against chemical and biological threats. Just as the chemicals may be invisible, the ability of textiles to withstand threats can also be hard to detect. These include the permeation of the chemical through the clothing as well as the penetration and buildup of the hazards over time and the degradation of protective textiles.

As Geng writes, “No chemical-resistant glove will keep the bad stuff out forever. You need to know how long a resistant glove can hold out, and when it needs to be thrown away.”

The 2PS approach

Even given current economic uncertainties, there are opportunities for textiles in protective and defense markets as well as health, hygiene and environmental protection. The 2PS approach—Products (P) and Processes (P) as a System (S)—offers a sensible path for the textile industry to navigate these challenging markets, and the chemical and biological protective textiles sector is particularly suited for adopting the system’s approach.

Major agencies, such as the Defense Advanced Research Projects Agency and the Biomedical Advanced Research and Development Authority, are involved in such approvals and play vital roles in initiating and funding projects. Because getting regulatory clearance and approval for defense applications is complex, these collaborative opportunities can be a useful pathway.

Given the complex challenges in handling toxic chemicals that belong to different classes (blister agents, nerve gas, toxic industrial chemicals and others), simply using a high surface area adsorptive substrate may not be a panacea. Currently, an approach involving multiple disciplines is the best solution to address this problem.

The U.S. Army Natick Soldier Systems Center has been at the forefront of research to develop a universal Personal Protective Equipment (PPE) substrate to tackle chemical and biological agents. Although this is a tall challenge, the effort is much needed and will move the research forward in chemical, biological, radiological and nuclear defense.

Research is ongoing to utilize metal oxides and other compounds to give multiple functionalities to fabrics. The MOF approach is also being investigated in a few academic and research laboratories, which can be used in next-generation defense technologies.

Participants and strategies

The advanced textiles sector lends itself well to small- and medium-scale enterprises, which are nimble and hence have the freedom to take a “detour,” if necessary, to enable timely success. These companies are better suited to adopt systems and combination approaches involving different fields and multiple entities toward successful commercialization.

There are opportunities to avail funding for such projects from the federal government through multiple agencies in the U.S. Dept. of Defense, the National Science Foundation, the U.S. Department of Agriculture and the U.S. Department of Energy.

Marie O’Mahony, Ph.D., is an industry consultant, author and academic based in London.

Seshadri Ramkumar, Ph.D., contributed to this article. He is a professor at Texas Tech University, Lubbock.

TEXTILES.ORG

TEXTILES.ORG