As climate change and its cascading consequences draw ever more attention from industries across the board, agricultural textiles suppliers and manufacturers are also taking note, devising ways to help mitigate its impact.

Varied yet intertwined concerns

Extreme weather patterns and temperatures are driving the need to better protect livestock and crops from excessive heat and cold, rainfall, and flooding as well as damage from hail, snow and the like. Climate change has also resulted in more aggressive insect infestations, making pest control a growing concern.

Sustainability concerns are another issue as more people become aware of the relationship between their carbon footprints and climate change. This is driving greater consumer interest in recyclability and in backyard food gardening.

Sourcing and transportation are another concern, particularly reducing the carbon footprint associated with getting materials from point A to point B, achieving cost savings by sourcing closer to home and greater predictability in obtaining supplies.

This article explores several textile options available to farmers and growers designed to help them address some of the challenging climate change issues they’re facing.

Housing animals, supporting garden centers

Headquartered in Beamsville, Ont., Canada, and in Buffalo, N.Y., OutFront Portable Solutions specializes in temporary and permanent garden center compounds as well as in dome-style buildings offered under the XL Shelters brand and used primarily for agricultural and industrial storage and workshops, says Ed Vander Vegte, the company’s business development manager, special projects and R&D.

Garden center structures are constructed with a metal frame and vinyl covering or woven polyester with a PVC-coated shade mesh. Included in the compounds are benches, carts and security fencing as needed. The shelter domes consist of a metal frame with a cover of high-density polyethylene. They are available in various widths and in “endless” length options, says Vander Vegte, adding that the company has built them more than 500 feet long. In agriculture, they’re being used for hay and straw storage, farm equipment storage and repair, workshops, silage covers and more.

Recently the domes have been deployed to house young animals like calves and kids (goats).

“This requires extra options for good airflow to prevent methane buildup and sickness among the young animals,” he says, explaining that the dome’s height enables a good flow of fresh air, creating a healthier environment. “The foundations for these buildings can be quite flexible, as they can be built on concrete block bases, containers, or piers and foundation walls.”

Designed to meet all local weather/snow load conditions, less expensive than traditional steel buildings and more mobile, the domes provide livestock herds with shelter while being raised. Once they’ve been sent to market, the empty dome can be used for storage.

Demand for the domes as a whole is “reasonably stable,” says Vander Vegte, with those used for housing young-animal stock experiencing small but regular growth. Demand for OutFront’s garden center compounds remains steady.

Known as show or cashier tents and used to expand existing retail space or to create new selling areas, the centers are generally installed as temporary structures by those outlets that already have permanent areas. The temporary textile structures can be built for permanent use, although this requires a heavier, engineered support structure, says Vander Vegte. The structures, which can be installed in different configurations, sizes, lengths and roof styles (rounded or peaked), can be ordered with custom logos and banners.

One of the biggest changes Vander Vegte sees happening in garden centers is consumers shifting to food-producing plants, a move that hasn’t negatively affected that market.

“The average homeowner is spending less money on ornamental stuff and investing in food-production gardening for their families and their own use,” he says. “People are still buying flowers. But if you go into the garden centers in the spring, the selection of vegetables, herbs and such have more prominence than ever before.”

Vander Vegte says OutFront is looking for new, lighter-weight, more durable and recyclable fabrics as well as for North American-made products.

Keeping livestock comfortable

Used to help regulate temperature and provide protection for livestock such as poultry, hogs and cows housed within barns, the PVC agricultural barn curtains from Herculite® Inc. are designed to maintain a comfortable interior climate even in extreme hot and cold weather conditions, says David Eichelberger, director of sales for the company.

“The temperature, humidity and air quality inside of the barn is crucial to the health and comfort of the animals. It helps to keep them calm, eating properly and avoids sickness,” he explains. “The curtains moderate temperature on both ends of the spectrum, allowing airflow for cooling, blocking the wind and keeping the interior warmer on cold days.”

Headquartered in Emigsville, Pa., Herculite has been manufacturing flexible PVC composite textiles for more than 60 years, says Eichelberger, providing an array of brands like Weblon Regatta® for boat and crew protection, as well as solar brands such as Weblon Coastline Plus®, Patio 500® and Architent® for tents and structure fabrics, among others.

The domestically produced curtains are made to order to fit the customer’s barn style and can be sized via the company’s proprietary online Curtain Builder. This tool allows customers to specify the fabric, as there are several USA-made fabric options available to accommodate barn style, animals being housed, length, width, hem style and locations.

Eichelberger says the company has seen demand for its barn curtains rise, with sustainability also “becoming a larger part of the conversation.” In response, Herculite recently partnered with Renegade Plastics® to develop a recyclable curtain intended to reduce the amount of waste being burned or directed to landfills.

Launched in 2023 and dubbed “Herculite with Renegade,” the curtains incorporate Renegade’s proprietary polypropylene-based fabric Renegade PPI-210, says Curran Hughes, Renegade’s president. Headquartered in Golden, Colo., and Green Bay, Wis., the company has a mission to move the textile industry toward greater “sustainability and circularity” through its portfolio of polypropylene-coated textiles. These textiles can be recycled by most plastics recyclers accepting polypropylene material, says Hughes, adding that typically no special fabric recycling equipment is necessary.

“Agricultural curtains will need to be cleaned before recycling,” says Hughes. “But Renegade customers are having a lot of success ensuring their scrap and waste fabrics do not go to the landfill.” Eichelberger says that in many areas, customers can contact recycling centers that will pick up the curtains.

Thwarting pests, withstanding weather

Headquartered in Holly Springs, N.C., Acadian Industrial Textiles is a fabric distributor and wholesaler serving the North American market, supplying textiles sourced from partner companies to industries including agriculture, horticulture, industrial, trucking and recreational, says Shawn Paul, president and CEO.

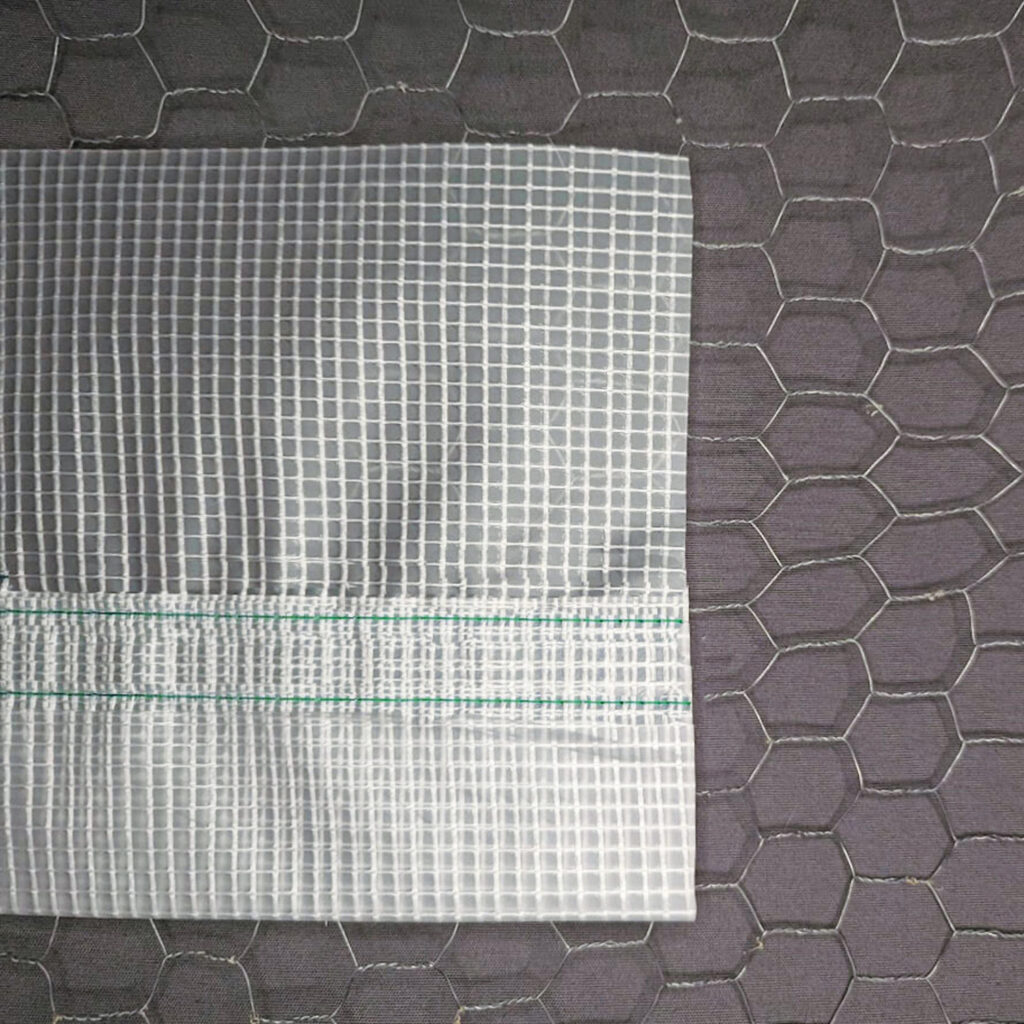

Fabrics for shade, grain, insect, bird/hail netting, greenhouse curtains and ground covers are used by those in agriculture and horticulture. For example, the company’s ground cover textiles are constructed with woven polypropylene tape yarns with a UV additive and come in carbon black or HALS (hindered amine light stabilizers) in white. They will block weeds, which reduces or eliminates the need for weed killers, and black ground covers can also warm the soil through transferring the sun’s heat, which improves planting conditions.

“Increasing the soil temperature by a degree or more can make it more hospitable for planting,” Paul explains. “This is also part of an integrated pest management program [IPMP]. If fruit drops, farmers can easily clear the ground cover to prevent animals or insects from being attracted to decomposing fruit.”

Depending on their permeability, ground covers can also reduce watering requirements, for example by allowing rainwater to flow through the fabric. Paul says there’s also no need to remove permeable covers during rain. Permeable ground covers can eliminate the need to run water lines under the fabric since the water from sprinklers will reach the plants. Most important, ground covers allow users to better manage volatile weather conditions, such as heavy rains, flooding, sudden cold fronts and high temperatures. For example, white ground covers can reflect some of the sun’s light and heat away from the plant’s roots.

The insect netting combines knitted HDPE with a HALS UV additive. Its purposes are keeping insects, birds and other pests away from crops, playing an integral role in a comprehensive IPMP. Insect netting also offers protection from hail and high temperatures and prevents the transmission of diseases being spread from pests and birds to the plants, says Paul.

Although insect netting is available in different pore sizes, Paul says customers are looking for smaller and smaller pore sizes to keep bugs from flying through the netting. As such, sales for 50 mesh (“50 yarns in 1 square inch of fabric in the warp direction,” she explains) are climbing. But there are some downsides that come with smaller pores, such as reduced airflow under the netting, which can create a less welcoming environment for bees, farmers and crops and also cause mildew growth on the plants.

As for ground covers, while sales of wovens are holding, demand is swinging to nonwoven fabrics—a variant of the product. These cost less and take up less space, but they don’t last nearly as long, sometimes only one season, Paul says. Sales of white covers are also growing as people learn more about their benefits, which includes reducing the need for electric fans or other ventilation in greenhouses.

Paul says multiple studies are being conducted by universities and manufacturers as to how different colored textiles might repel insects, potentially reducing the use of pesticides. Research on light transmission and diffusion through fabrics and the ways this affects crops is also underway.

Pamela Mills-Senn is a Seal Beach, Calif.-based freelance writer.

SIDEBAR: Cool animals graze more

Dining alfresco for humans often involves relaxing beneath a canopy or umbrella, especially under the hot summer sun. Livestock around the world are also having that opportunity—and avoiding heat stress—through the deployment of portable shade systems manufactured by Shade Haven of Viroqua, Wis. The structures cover 600 or 1,200 square feet, deploy without needing a power source and, as shown in the photo, are light enough to be transported by ATV. They set up in about 15 minutes with only one person, and if a storm threatens, they can be closed up in two minutes.

“It was developed by farmers, for farmers,” says company president Reed Doerr. “It came about as a solution to a problem company founder Vince Hundt had on his own farm.”

Keeping cows cool means better grazing and thus milk and beef production, but the benefits of better conditions can aid any livestock. And changing their field location means they can be kept on dry ground, preventing the overuse of natural shady areas. Rotational grazing also more widely distributes the pasture’s fertilizer instead of it becoming concentrated near trees or buildings where the animals would otherwise retreat to beat the heat.

The shade structure includes a steel frame and a shade of 90% knitted polypropylene mesh made by BTL Liners of Prineville, Ore.

Shade Haven began in 2012; its first sale was the following year to a century farm in Paoli, Wis., and that mobile unit is still in daily use during the grazing season. In 2023 the company moved to its own facility for manufacturing and assembly and introduced a street fair version of the product.

TEXTILES.ORG

TEXTILES.ORG