Much work in the textile industry is happening regarding removing PFAS and formaldehyde from finishes to create greener alternatives.

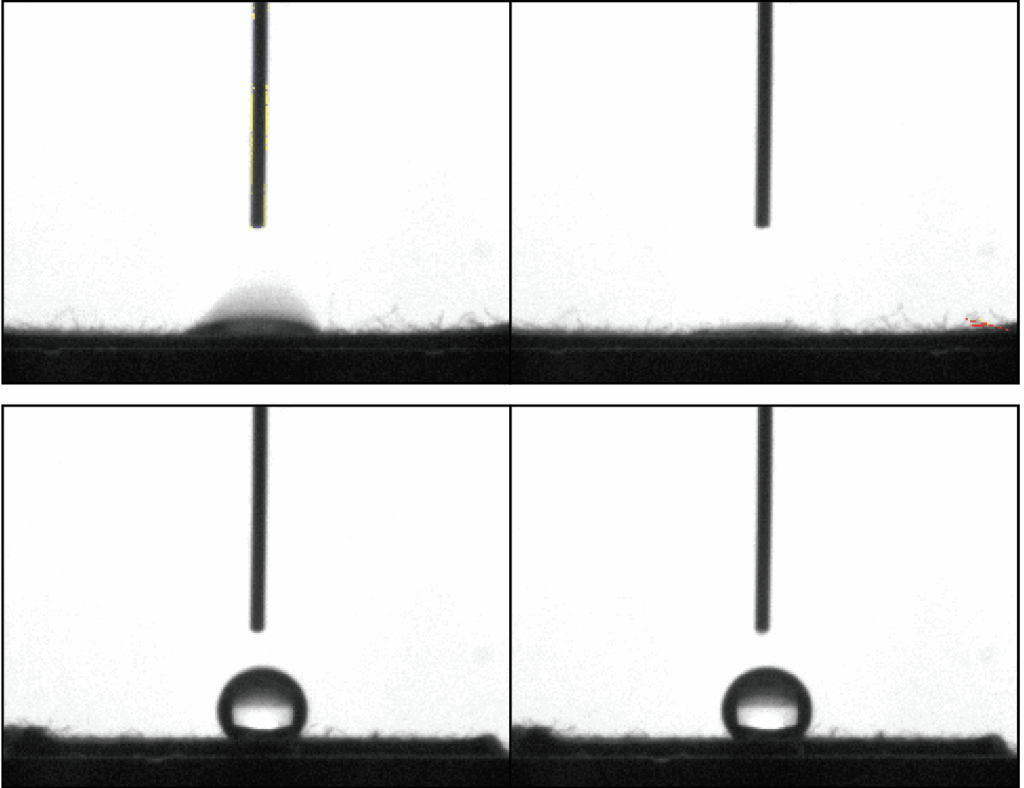

North Carolina State University (NC State) researchers have created a polymer finish by inserting bio-based epoxy groups into cottonseed oil to create epoxidized cottonseed oil (ECSO). The bio-based polymer finish bonds strongly with cotton’s cellulose fibers, making the fabric wrinkle-resistant and water-repellent.

Future studies will measure additional performance factors in ECSO-treated cotton fabric, including tear strength, durability and wrinkle resistance, and, says lead researcher Richard Venditti, “oil-in-water emulsions and other catalysts.” Venditti is a professor of forest biomaterials, paper science and engineering at NC State.

“If we can achieve our goal of changing the properties of the cotton fabric—making it anti-wrinkle, anti-staining and water-resistant—using a water-based process, we’ll have a green process for putting a bio-based material onto cotton as a replacement for formaldehyde- and PFAS-based finishes,” says Venditti in a release about the work.

The research drew on previous NC State research into cottonseed oil and was presented at the fall meeting of the American Chemical Society in August. It was funded by Cotton Incorporated and an Agriculture and Food Research Initiative from the U.S. Department of Agriculture’s National Institute of Food and Agriculture.

TEXTILES.ORG

TEXTILES.ORG