With technology taking over and automation ascendant, manufacturers are reinventing themselves and their operations to maximize efficiency, effectiveness, safety, reliability, productivity and profitability.

The equipment they choose, especially when skilled labor is in short supply, doesn’t replace craftsmanship—it enhances it. We asked our equipment suppliers to tell us about the advantages of their latest innovations and how they can solve manufacturing problems.

Purchasing new equipment—from sewing, sealing and cutting to measuring, printing and testing—is an investment in process as well as progress. The equipment companies that sent us information for this showcase answered our questions about durability, versatility, cost effectiveness, reliability, speed, easy operation, sustainability, flexibility, efficiency and dozens of factors that contribute to the production and long-term profitability of specialty fabrics manufacturers.

To try to dig a little deeper, I responded to each product submission asking for responses to four questions:

- What are the trends in the equipment industry? Is equipment becoming more multifunctional, or more specialized? Larger, or more compact? What do purchasers value most?

- Is increasing automation a universal factor?

- What kinds of support/service/training do you offer customers? How important is this to them?

- In your part of the industry, where are the growth areas, and why?

A few people responded to my brief, informal survey, and as I looked through their responses, the punchline from that old joke about “Do you believe in situational ethics?” came back to me: “It depends.”

It isn’t always easy to find the commonalities among manufacturers that make everything from awnings and tents to water bladders and parachutes to smart wallcoverings and medical implants, using equipment that ranges from calendering, coating and cutting to plotting, sewing and sealing to packaging, storing, printing and testing. Manufacturing unique products involves some unique challenges, as well as unique opportunities. But I did find some recurring themes among the responses from these equipment suppliers—one of which is that each business will find a unique path to success with the management, vision, employees and equipment they put to use. Following, throughout this product showcase, are the responses I received, in their own words.

Focus on Flexibility

HOW CAN I … cut patterns in textiles more effectively?

HOW CAN I … cut patterns in textiles more effectively?

SOLUTION: SMRE 330 Conveyor Cutting Plotter can cut technical textiles to any length. With the use of SMRE’s SPLIT BOX software, patterns that are larger than the cutting frame of the unit can be easily cut. It’s also capable of simultaneously mounting a rotary knife, drag knife and punching tool on a single cutting head to effectively cut thermoplastic-coated fabrics, films, acrylics and other technical textiles with a single cutting plotter.

RECOMMENDED FOR: Sails and sunshades, tents and shelters, inflatable products, ground covers and similar products.

SMRE America Ltd.

+1 440 973 4445 | www.smre-america.com

HOW CAN I … weld and glue technical textiles?

HOW CAN I … weld and glue technical textiles?

SOLUTION: SMRE SM-216 welding and gluing head motion is controlled via a rack and pinion system coupled with SMRE’s Intelligent torque system. The combination of the rack and pinion system provides the user with the tools to produce seams of unmatched strength and appearance. Low maintenance, easy to use and reliable.

RECOMMENDED FOR: Awnings and shades, pergolas, pool covers, containment bladders and more.

SMRE America Ltd.

+1 440 973 4445 | www.smre-america.com

HOW CAN I … blend a screw-stud with the design and color of my fabric?

HOW CAN I … blend a screw-stud with the design and color of my fabric?

SOLUTION: CAF-COMPO Screw-Stud is a composite self-tapping screw stud for use in fiberglass, wood and other composites. The stud is the lower part of a snap or ring-spring press fastener system and will fit any regular ring spring socket, no matter the material or supplier. A version with a metric thread makes it possible to solve the corrosion issue on any aluminum surface. UV-stabilized, tested to hold 500N and available in white variants, light grey, black or any custom color to match the deck color of a yacht.

RECOMMENDED FOR: Marine cushions, covers and blinds.

SUREFAS

+31 184 694 456 | www.surefas.com

HOW CAN I … assure wrinkle-free welding?

HOW CAN I … assure wrinkle-free welding?

SOLUTION: The Leister VARIANT T1 Hot-Air Fabrics Welding Machine includes advancements to the prior generation of fabric welding tools and the ability to use pre-set welding parameters. Combined with a slim, compact design, its maintenance-free hot air blower and newly designed nozzle enable constant, wrinkle-free welding. A mobile dual-axis helps ensure better welds, and the easy-to-view display with intuitive, one-button “e-drive” technology make it user-friendly. Available with a weld seam width of 20 or 40 mm.

RECOMMENDED FOR: Structures and truck tarps.

STANMECH Technologies Inc.

+1 905 631 6161 | www.stanmech.com

HOW CAN I … keep grommets and washers corrosion-free?

HOW CAN I … keep grommets and washers corrosion-free?

SOLUTION: Stainless steel grommets and washers are made of non-porous, 304 SAE stainless steel that ensures durability in the most adverse environments. Ropes will not wear through, and it will not go “out of round” under tension. Grommets and washers offer UV- and scratch-resistance and superior resistance to rust, stains, pitting and corrosion.

RECOMMENDED FOR: Marine canvas, flags, banners, tie-downs and tarps.

Scovill Fasteners

+1 706 754 1000 | www.scovill.com

HOW CAN I … solve the issue of zippers wearing down from outdoor elements?

HOW CAN I … solve the issue of zippers wearing down from outdoor elements?

SOLUTION: YKK’s MARINE MATES® zippers are designed for protection from damaging environmental elements including sun, wind and water. Unique line of VISLON® zippers resists corrosion and adds protection from the damaging UV rays. Available in #10 size. Company also offers TA single pull and TX double pull automatic locking plastic sliders that are resistant to salt water.

RECOMMENDED FOR: Tents, automotive

tops, pool covers and boat tops.

Quality Thread & Notions

800 521 4308 | www.qualitythread.com

Focus on Ease of use

HOW CAN I … better test for lightfastness?

HOW CAN I … better test for lightfastness?

SOLUTION: TruFade is a lightfastness tester (LFT) with a compact design, simple operation and intuitive software that can be operated with minimal training. Offering swift changes between US and ISO standards, it significantly decreases lab downtime. The wide opening door and comfortable height allow for easy access in loading and unloading specimens.

RECOMMENDED FOR: Labs and manufacturers with varied lightfastness testing needs and relatively lower capacity demands, for testing products ranging from sportswear and outdoor upholstery to golfwear and tents.

James Heal / ATI Corporation

+1 864 989 0566 | www.aticorporation.com

HOW CAN I … simplify testing of water vapor transmission rates?

HOW CAN I … simplify testing of water vapor transmission rates?

SOLUTION: The FX 3180 CupMaster is a fully automatic gravimetric water vapor transmission rate tester that weighs samples at regular intervals during testing, and prevents condensation in case of a power failure with an innovative heating system. Unit has a capacity of 12 or 15 cups (depending on the model); once the cups have been loaded and testing has started, no more handling is required, meaning that testing can be done overnight and over the weekend. Results and climate data can be observed at all times by Virtual Network Computing.

RECOMMENDED FOR: Suppliers of plastic films for building and packaging industries, nonwovens and membranes.

ATI Advanced Testing Instruments Corp.

+1 864 989 0566 | www.aticorporation.com

HOW CAN I … improve stitch and trimming consistency?

HOW CAN I … improve stitch and trimming consistency?

SOLUTION: The PLK-J6040R is made with the latest technology in X-Y axis sewing machines, addressing issues with error proofing, thread tension consistency and consistent stitch quality, with motor-driven trimming. Major benefits to users include improved stitch and trimming quality, better troubleshooting and the use of electronic adjustments in place of mechanical adjustments.

RECOMMENDED FOR: Automotive products, medical devices, apparel and fall safety markets.

Mitsubishi Electric Automation Inc.

+1 817 251 7475 | https://us.mitsubishielectric.com/fa/en

HOW CAN I … eliminate the need to prepunch holes for fasteners?

HOW CAN I … eliminate the need to prepunch holes for fasteners?

SOLUTION: Scovill Fasteners’ Self-Piercing Grommets and Washers feature sharp-edged barrels and thick, raw material and premium brass to eliminate the need to prepunch holes during application, and also provide durability against abrasion. Major benefits for users include increased durability, faster application, and greater sustainability and productivity.

RECOMMENDED FOR: Flags and banners, awnings and marine applications.

Scovill Fasteners

+1 706 754 1000 | www.scovill.com

HOW CAN I … find a reliable, easy-to-use generator for eyelet welding?

HOW CAN I … find a reliable, easy-to-use generator for eyelet welding?

SOLUTION: Forsstrom’s machine model FG 120 is a small 3 kW RF-generator with a built-in control system for welding parameters such as time and power. Suitable as a stand-alone unit for eyelet welding, it can also be used for inline RF applications such as medical and packaging. Small, safe, efficient and easy to use, it works well with any plastic eyelet presses in a variety of applications.

RECOMMENDED FOR: Manufacturers needing to weld on plastic eyelets, or needing a small and reliable RF-generator for other purposes.

Forsstrom High Frequency AB

+46 5 236 6660 | www.forsstrom.com

HOW CAN I … regularly monitor welding quality and consistency?

HOW CAN I … regularly monitor welding quality and consistency?

SOLUTION: Forsstroms’ traveling TDW-Mega RF-welding machine is designed to make consistently straight, strong and durable welds throughout the working day. Unit can weld up to 16 inches by 55 inches or longer in one weld, reliably and efficiently. It’s equipped with the program IQ, which monitors the performance of the machine and its status at all times.

RECOMMENDED FOR: Products needing

a strong weld, such as tents, structures, oil booms, liquid tanks, truck and boat covers.

Forsstrom High Frequency AB

+46 5 236 6660 | www.forsstrom.com

HOW CAN I … improve sewing on heavy-duty fabrics?

HOW CAN I … improve sewing on heavy-duty fabrics?

SOLUTION: Seiko’s LCWN cylinder bed industrial sewing machine has a higher needle bar stroke and a higher alternating presser foot lift that allow for easier stitching of heavier materials. Moving area is covered by a newly designed arm casting for safety; the face plate also has a new design for easy handling.

RECOMMENDED FOR: Sewing bags, luggage, leather goods and auto interiors.

Hoffman Brothers

800 323 9120 | www.hoffmanbrothers.com

HOW CAN I … clean dirty tents faster and more efficiently?

SOLUTION: The BK series tent washers (three sizes available for different amounts of material) will clean all sizes of tents, structures and sidewalls with minimal effort and time. The compact, fully automatic machine allows users to load the unit, press “start” and then do other jobs; three wash cycles (light, regular and heavy-duty) can be chosen, depending on how dirty the tent is. Can be filled with a garden hose, and also has a plug-and-go electrical system, to cut plumbing and wiring costs.

RECOMMENDED FOR: Party and event rental companies.

CCC Washers Inc.

800 242 6833 | www.cccwashers.com

HOW CAN I … cut heavy and thick materials?

HOW CAN I … cut heavy and thick materials?

SOLUTION: The Carlson Design RTi Reciprocating System uses a .75-inch steel reciprocating blade to cut materials that can’t be handled with standard rotary or drag blade holders. The high-performance reciprocator cuts into a porous consumable substrate (like polystyrene) atop specially engineered turbo tables, designed to provide the flattest possible cutting surface while also providing maximum airflow for easier operation.

RECOMMENDED FOR: Cutting carpet, leather hides, gaskets, multiple plies of woven fabric, and thick materials.

Carlson Design

+1 918 438 8344 | www.carlsondesign.com

HOW CAN I… feed buttons into a sewing machine automatically?

HOW CAN I… feed buttons into a sewing machine automatically?

SOLUTION: The JK-T1903BR button robot sewing machine automatically loads buttons into sewing machines and has them ready to be sewn in seconds. Unit speeds up the overall cycle time and eliminates the need for the operator to put hands in the sewing area to attach buttons.

RECOMMENDED FOR: Any product that needs buttons attached.

C and C Enterprise / Jack of the America’s

+1 931 739 7499 | www.candcenterprise.com

Focus on Economy/ROI

HOW CAN I … eliminate measuring mistakes and digitize the template process?

HOW CAN I … eliminate measuring mistakes and digitize the template process?

SOLUTION: The Proliner is a portable digital measuring tool with patented technology: measuring with a wire. At the end of the wire is a metal measuring pen that allows the user to mark relevant points, which are directly translated into a digital DXF CAD file. Straight, curved and very complex shapes can be measured quickly and accurately from every position.

RECOMMENDED FOR: Marine, canvas/textile, glass, stone and construction industries.

Prodim

888 229 3328 | www.prodim-systems.com

HOW CAN I … make my small fabrication shop more competitive?

HOW CAN I … make my small fabrication shop more competitive?

SOLUTION: The HEMTEK ST is an efficient and affordable vinyl welder. Designed for the quick hemming of vinyl—up to 39 feet (12 meters) per minute—users can hem vinyl for fabric structures, truck curtains or tarpaulins from corner to corner in a single pass. Capabilities include hem welds, pole pockets and hems with rope.

RECOMMENDED FOR: Vinyl products.

Leister Technologies

+1 630 760 1000 | www.leister.com/hemtek

HOW CAN I … satisfy the requirements of AATCC test methods on drying rates?

HOW CAN I … satisfy the requirements of AATCC test methods on drying rates?

SOLUTION: The DryRate 201 is a fully automated test instrument for determining the drying rate of a fabric based on the evaporation rate that occurs when the fabric is placed in contact with a prescribed amount of water in contact with a heated metal plate and held to a constant temperature. The built-in anemometer (wind speed sensor) and infrared thermocouple probes monitor testing conditions and specialized software calculates the end time of each test, the sample’s drying rate, and generates test reports.

RECOMMENDED FOR: All types of fabrics including knits, wovens, nonwovens and fabrics taken from end product use.

SDL Atlas

+1 803 329 2110 | www.sdlatlas.com

HOW CAN I … streamline production and boost efficiency?

HOW CAN I … streamline production and boost efficiency?

SOLUTION: The SMRE SM-100 Linear Sewing Machine is easy to operate with sewing head movement that is precisely controlled by a rack and pinion transmission system. Fabric stays stationary while the sewing head moves during the sewing cycle and ensures consistent seam quality and fast paneling and hemming of technical textiles.

RECOMMENDED FOR: Awnings and blinds, sails and sunshades, tents, shelters and industrial speed doors.

SMRE America Ltd.

+1 440 973 4445 | www.smre-america.com

HOW CAN I … solve floor space issues for material rolls?

HOW CAN I … solve floor space issues for material rolls?

SOLUTION: Vertical Carousel does the heavy lifting for the operator, eliminating the need to manually lift heavy rolls. The carousel uses overhead space to store the roll and, with the push of a button, brings the roll down for further handling/processing at an ergonomic height.

RECOMMENDED FOR: Fabrics, plastics, laminates and other materials.

Vidir

+1 204 364 2442 | www.storevertical.com

HOW CAN I … save time on welding?

HOW CAN I … save time on welding?

SOLUTION: The Seamrover DD Industrial’s design allows for improved production time by welding in both directions. The operator can weld to one end, switch the handle’s direction and weld coming back. Unit’s forward or backwards operation allows for improved seam visibility and has an SD card slot for data recording. Curve weld, webbing and seam width options are available.

RECOMMENDED FOR: Tents, tarps, covers and geomembranes.

Miller Weldmaster

+1 330 833 6739 | www.weldmaster.com

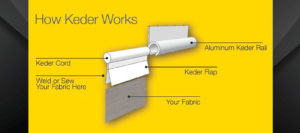

HOW CAN I … minimize damage to my fabric from repeated usage?

HOW CAN I … minimize damage to my fabric from repeated usage?

SOLUTION: DuraKeder fully bonded keder’s bonding process adheres fabric all the way around the cord. Minor damage of the fabric from repeated use will not render the keder unusable; the product’s longer life enables long-term use. Available in a wide variety of sizes and colors.

RECOMMENDED FOR: Awnings, tenting walls, boat curtains.

Keder Solutions

888 727 7050 | www.kedersolutions.com

HOW CAN I … handle small loads without a forklift?

HOW CAN I … handle small loads without a forklift?

SOLUTION: Lift and load quickly and safely with the Makinex Powered Hand Truck PHT-140, which allows one person to handle small equipment or bulky goods weighing up to 309 pounds. A quick and easy alternative to a forklift, the unit features a 12V 25 Amp linear actuator designed for easy operation: the lifting arm reach is controlled by lifting or lowering the handles, and arm height is controlled by a simple thumb switch. Lightweight and maneuverable, it folds flat for transport and storage, and includes a hook attachment for handling small equipment and machinery fitted with a lifting eye.

RECOMMENDED FOR: Workshops, warehouses, depots, distribution companies and hire and rental operations.

Makinex Construction Products

+1 310 383 5730 | www.makinex.com

Focus on Efficiency

HOW CAN I … keep track of broken needles during sewing operations?

HOW CAN I … keep track of broken needles during sewing operations?

SOLUTION: The Needle Dispensing Trolley manages the process of finding and documenting broken needles, saving time and labor during sewing processes. Mobile needle dispensary documents broken needles, helps in finding them, and stores new needles and processing tools. It can be moved towards the sewing machine, instead of making the operator move to the exchange station, reducing idle time and increasing output.

RECOMMENDED FOR: Markets with medium-to-large sewing production.

Groz-Beckert USA Inc.

+1 803 548 4769 | www.groz-beckert.com

HOW CAN I … visually check for color harmony under different lighting conditions?

HOW CAN I … visually check for color harmony under different lighting conditions?

SOLUTION: The Simultaneous Color Viewer (SCV) allows a visual side-by-side comparison of colors under four different light sources: daylight (D65 or D50), LED (3500K), store light (4100K CWF or TL84) and home light incandescent (CIE A). A UV light detects optical brighteners, whitening agents and fluorescent dyes and pigments. An easy way to check color constancy, color harmony and color matching. Spring-loaded viewing platform allows easy viewing of thicker materials, such as carpet samples.

RECOMMENDED FOR: Color matching, inspection and aesthetic appraisal.

GTI Graphic Technology Inc.

+1 845 562 7066 | www.gtillie.com

HOW CAN I … develop the best fastening methods for our products?

HOW CAN I … develop the best fastening methods for our products?

SOLUTION: YKK (USA) Inc. offers more than 1500 styles of plastic and metal zippers, hook-and-loop tape fastening systems, snaps, buttons, buckles and other fasteners for apparel, protective and tactical equipment, luggage, furniture and sporting goods. Along with the company’s manufacturing locations, the Field Tech Centers help customers develop the best manufacturing solutions when installing YKK’s fastening products, supporting the need for fast, custom market response, whether the need is for sewing, welding, gluing or product assembly.

RECOMMENDED FOR: Apparel and industrial applications, including tactical, medical, furniture, hygiene and sports products.

YKK (USA) Inc.

+1 770 421 2386 | www.ykknorthamerica.com

HOW CAN I … accurately test wash shrinkage of textiles?

HOW CAN I … accurately test wash shrinkage of textiles?

SOLUTION: To meet AATCC standards, the Vortex M6 commercial-grade washer is specifically designed to address the most recent revisions of the Research Committee’s monograph on Home Laundering Technology (RA88). Equipped with a controller, heavy-duty variable speed motor and custom water temperature and flow controls, the programmable Vortex M6 offers consistency and advanced control of the wash cycles, and can be calibrated and adjusted like other lab instruments.

RECOMMENDED FOR: Textile manufacturers and distributors that test to AATCC home laundering test methods.

SDL Atlas

+1 803 329 2110 | www.sdlatlas.com

HOW CAN I … hem and close long, narrow filter bags faster and more effectively?

HOW CAN I … hem and close long, narrow filter bags faster and more effectively?

SOLUTION: Highlead Model GC 2268-2BXL sewing machine solves the problem of handling long and/or narrow filter bags or filter material in the round: its long 37-inch cylinder arm is able to sew in areas not reachable with other machines. The bags can be closed on both sides first and then finished (hemmed) second, rather than having to use a shorter machine first and close the sides afterwards.

RECOMMENDED FOR: Stitching large cylindrical articles such as filter bags, filter mesh, environmental protection products, cleaning supplies, sporting goods.

Friedlander Sewing Machine Co. Inc.

+1 631 754 2121 | www.friedlandersewing.com

HOW CAN I … create a better weld and finish for a wider variety of materials?

HOW CAN I … create a better weld and finish for a wider variety of materials?

SOLUTION: A fully automatic welder using impulse technology, the Ares Plus features push-button operation: the operator places the fabric against guides, and the machine does the rest. Unit offers 63 unique settings to cover all ranges of interior and exterior sun protection materials, plus 34 group settings for more advanced operations. Patented “Seamless” technology also creates a superior finish.

RECOMMENDED FOR: Interior and exterior sun protection products.

Matic S.A.

+1 301 327 1881 | www.matic.es

Focus on Productivity

HOW CAN I … increase tent installation efficiency and reduce labor costs?

SOLUTION: The Tent OX™ system takes over the most time-consuming, dangerous and strenuous commercial tent installation tasks (stake driving, stake pulling, pushing center poles, movement of tent fabric and other materials from truck to tent site), so crews can complete their tasks more quickly and safely. Ten attachments, including a hydraulically driven stake driver, stake puller and keder fabric roof panel pullers, are custom-mated with a four-wheel-drive articulated loader that also carries heavy loads without damaging delicate surfaces like lawns and sports fields. Tent OX lowers labor costs and reduces time on the job, helping tent professionals raise their profit ceilings.

RECOMMENDED FOR: Commercial tent and party event installation companies who regularly put up a minimum of 40-foot-wide pole tents and larger, and nearly all structure tents.

Tent OX

800 878 0065 | www.tentox.com

HOW CAN I … help engineers optimize the design of their manufactured products and identify and prevent quality control issues?

HOW CAN I … help engineers optimize the design of their manufactured products and identify and prevent quality control issues?

SOLUTION: The eXpert 7603 Single Column Universal Testing System allows operators to gather accurate data on the material properties of their products, like strength, elasticity and resiliency. The data enables them to make educated decisions regarding product formulation, process control and product life. ADMET machines are configured to the exact needs of the customer to ensure ease of use, accuracy and repeatability—saving companies money when compared to purchasing third-party testing services, or when considering the cost implications of commercializing a product that wasn’t properly tested.

RECOMMENDED FOR: A broad range of industries including textiles, plastics, elastomers, medical devices, adhesives

and packaging.

ADMET Inc.

+1 781 769 0850 | www.admet.com

HOW CAN I … find an easy and affordable way to visually test for color matching?

HOW CAN I … find an easy and affordable way to visually test for color matching?

SOLUTION: The ColorMatcher inspection series is an effective way to visually test for metamerism and color harmony under ASTM-D1729 viewing conditions. It’s available in four models, and each includes five light sources, an illuminated push button control, one-touch automatic light source sequencing and ColorGuard II lamp tracking software. Floor stand and storage options are available. Viewing areas range from 19 x 28 x 20 inches to 30 x 64 x 30 inches (H x W x D).

RECOMMENDED FOR: Comparing colors of textiles, consumer goods and dyes under different light sources.

GTI Graphic Technology Inc.

+1 845 562 7066 | www.gtilite.com

HOW CAN I … create a large sample viewing area for visual comparison of colors?

HOW CAN I … create a large sample viewing area for visual comparison of colors?

SOLUTION: The GLE- Multi-source Overhead Luminaires utilize an innovative optically clear, UV-transmitting, prismatic diffusion lens for optimal light distribution. Available with three, four or five light sources. Standard units include a line cord, GTI ColorGuard II and a front-mounted selector/sequencer control panel. Up to 10 luminaires can be linked together. A wireless remote is also available.

RECOMMENDED FOR: Checking the color of textiles, consumer goods and dyes under different light sources.

GTI Graphic Technology Inc.

+1 845 562 7066 | www.gtilite.com

HOW CAN I … find a high-speed, affordable dye-sublimation printer that doesn’t sacrifice quality?

HOW CAN I … find a high-speed, affordable dye-sublimation printer that doesn’t sacrifice quality?

SOLUTION: The Mutoh ValueJet 1948WX is built for real production-based printing. With its staggered four-head design, it prints at speeds up to 2,199 sq.ft./hr. Advanced features include a rear media feed lever for easy material handling, an HD take-up system, an easy-to-navigate control panel along with simple operation. This keeps the learning curve short and the focus on customers and profits. The printer provides high production performance at a competitive price.

RECOMMENDED FOR: Trade show graphics, promotional items, flags, interior decor, apparel.

Advanced Color Solutions

+1 951 359 2000 | www.advancedcolorsolutions.com

HOW CAN I … find a more efficient way to cut interior and exterior shades?

HOW CAN I … find a more efficient way to cut interior and exterior shades?

SOLUTION: The M1-PC utilizes nesting software to reduce waste and eliminate cut calculations, increasing capacity and cutting production costs. An easy-to-use interface does not require a skilled operator. Unit cuts in both the X and Y axes in the most efficient directions to minimize cut times, and features advanced material handling for getting material on and off the cutting table.

RECOMMENDED FOR: Interior and exterior shading products.

Matic S.A.

+1 301 327 1881 | www.matic.es

HOW CAN I … ensure the correct cut file for a job is selected quickly?

HOW CAN I … ensure the correct cut file for a job is selected quickly?

SOLUTION: Autometrix’s SpeedLoader is an add-on utility to its PatternSmith CAD, Nesting, and Machine Control software. The utility will allow cutter operators to simply scan a barcode on a work order, guaranteeing the appropriate file is loaded instantly. This removes the risk of human error when it comes to selecting the correct cut file for a job. Options can be set to load the file directly into the Plot environment, so the only step required by the operator is to press the “Start” button on the machine itself.

RECOMMENDED FOR: Industries that rely on precision cutting.

Autometrix

+1 530 477 5065 | www.autometrix.com

HOW CAN I … find a reliable tabletop viewing booth for color matching, harmony and constancy?

HOW CAN I … find a reliable tabletop viewing booth for color matching, harmony and constancy?

SOLUTION: The tabletop MiniMatcher series is an effective way to visually test for metamerism and color harmony under ASTM-D1729 viewing conditions. It is available in five models: the MM-1e and MM-2e provide three light sources with UV as an option. The MM-4e, MM-2448e and MM-2460e include five light sources with a built-in daylight timer, illuminated push button control and one-touch automatic light source sequencing.

RECOMMENDED FOR: Checking the color of textiles, consumer goods, dyes and fashion goods under different light sources.

GTI Graphic Technology Inc.

+1 845 562 7066 | www.gtilite.com

HOW CAN I … cut different types of materials with one machine?

HOW CAN I … cut different types of materials with one machine?

SOLUTION: The SMRE 375 static bed cutting plotter is a high-performance industrial unit designed to install multiple cutting and marking tools for technical textiles. By simultaneously mounting a rotary knife, drag knife, ultrasonic cutter and laser cutter on a single cutting head, the user can effectively cut sunscreens, thermoplastic-coated fabrics, films, acrylics and other technical textiles with a single machine.

RECOMMENDED FOR: Awnings, blinds, pergolas, sails, sunshades, tents, shelters, pool covers, tensile structures.

SMRE America Ltd.

+1 440 973 4445 | www.smre-america.com

Support and service: When the customer purchases a machine, we go out and train them on how to use it and the best way to prep tents for washing. We also have training manuals they can refer to for questions, or they can call us for any technical support. Our machines don’t need regular software updates, which makes them easier to use and less costly.

Trends and growth: Our machine is definitely specialized. The advantages are that it is a quick way to wash a tent without a lot of labor and time involved. Any time you can automate something it saves on labor, which is usually the biggest expense in most businesses.

Jenny Cole

Operations Manager, Charnecke Tents Inc./CCC Washers Inc.

Rosholt, Wisc.

Support and service: To guarantee compliance to industry standards, all light booths should be relamped every 2,500 hours. For customers that require traceable certification, GTI provides Certified Relamp Kits, which have been factory-tested and come with a certification that they meet published industry standards.

GTI also offers LiteSupport, an on-site audit and certification program to help users maintain inspection systems to industry standards. GTI will conduct an audit to determine the status of customers’ inspection systems, and work with them to develop a relamping and maintenance program. The LiteSupport program can include multiple viewers and locations.

Trends and growth: GTI is experiencing growth in the textile market and other industrial color markets (such as coatings and automotive). Users are becoming more aware of the products available; we participate in the AATCC, Techtextil and IFAI Expo trade shows and are offering a wider range of products at more affordable prices.

Brian Wolfenden

Field Marketing Manager,

GTI Graphic Technology Inc.

Newburgh, N.Y.

Support and service: With every machine we sell, we offer free technical and application support, via phone and email, for the life of the system. We offer varying levels of training and calibration to suit each customer’s needs and budget. Often we perform an ISO17025 calibration and training on-site once we’ve delivered a machine. However, there are more budget-friendly options, such as live online training sessions if preferred. We can customize calibrations and onsite service to meet customer needs.

Trends and growth: ADMET works with a wide variety of customers and industries. In the textile industry, I would say that most customers prefer the multifunctional advantages that our Universal Testing Machines offer (with various grips and fixtures to perform multiple tests, and software with robust analysis tools). However, some customers are looking to perform very specific and nonstandard testing applications, which allows us to tailor a test solution to achieve their unique goals.

I don’t believe that material testing machines will become automated to the point that they will replace humans in the near future. Our current level of automation options does provide more accurate and repeatable results than simplified and manually operated test set-ups. But these systems are designed for people to operate them and interpret the results.

Recently, we have seen more wearable technology companies reach out to us for testing equipment and advice. There is a strong desire to understand how well wearable technologies perform and endure when they’re pulled at and stretched over the body during normal use or exercise. Additive manufacturing is also growing and evolving. Materials from metal to plastic to fabrics are all being created with 3-D printers today. We are seeing more companies that want to mechanically test these 3-D printed parts in various ways to compare them to traditionally manufactured parts, and determine if they are suitable for inclusion in mass-produced assemblies.

Scott Carroll

Account Director, ADMET Inc.

Norwood, Mass.

Support and service: We have after-hours factory support as well as local technicians throughout North America who can be on-site within hours. Our factory-certified installers provide on-site training upon completion of installation of the carousel. Regular software updates don’t seem to be very important to our customers, as most of them are interested primarily in the mechanical advantages of an automated storage system, but we are seeing a movement toward software-controlled equipment being installed, which will create new opportunities.

Trends and growth: Equipment is becoming more specialized, as each company has unique space and operating constraints, which means more and more custom equipment is going out the door. We are seeing more interest in automation as more companies are focusing on increasing their output in their existing facilities.

Automation is a growing trend in nearly every industry. When you can tie your material storage into production equipment, you can eliminate the chance of a delay in supply, which means more uptime in your key profit centers—alongside the traditional advantages of automated storage systems (space savings, safety, retrieval time).

Automation and heavier-capacity machines are where we see growth, because companies are trying to increase output without compromising safety.

Dean Dueck

Marketing Manager, Vidir Machine Inc.

Arborg, Manitoba, Canada

Support and service: With our machine, training is necessary for more efficiency. We offer a series of videos, phone conferences, and will offer an annual training session for employees. Training is often not as important as it should be to our customers. Once the product is purchased, sometimes there’s not enough follow-up. Just how important is productivity and long-term profitability to these companies?

Trends and growth: The consolidation going on in the tent rental industry is, for us, a positive! Cash flow is … flowing again. Previously, companies were competing and undercutting each other in prices. In tent rental, there are two chances to make a profit: when you quote and price a job, and when working to get the project done at the lowest cost of doing business. That part is very labor-intensive. The goal of our product, Tent OX™, is to reduce the cost of doing business. It’s an investment—but offers incredible cost and labor reductions in use.

In this industry, it’s on-the-job training, so you don’t really need “pre-skilled” labor. The seasons can be short—and intense. So automation is always a help with the labor burden.

The growth comes from people who are willing to develop or invest in automation and technology: meaning, more efficiency!

Scott Woodruff

Founder, Tent OX

Enola, Pa.

Support and service: We sell primarily through our network of authorized distributors, all trained by us and with access to all of our resources. We also offer specialized training to end users in our Grapevine, Texas, office. This is very important to our customers because, as with sewing machine operators, there is a lack of experienced sewing machine technicians in our industry.

Trends and growth: The trend in the sewing industry is more automation to make up for the lack of skilled sewing operators—and also to combine multiple sewing operations on one machine. Both are very important. Our customers need to meet their production requirements with less experienced operators, and those are the concerns our equipment is designed

to address.

The growth areas are in the automotive and fall protection markets right now. Automation is the key word.

Brenda Childress

Supervisor of Sales and Operations, Automated Sewing Application Products, Mitsubishi Electric Automation Inc.

Grapevine, Texas

TEXTILES.ORG

TEXTILES.ORG