Photo: Kaveh Sardari.

Smart fabrics are still so new to the textile world, relatively speaking, that it’s necessary to start with a working definition. That’s what the first presenter, IFAI’s market research director Jeffrey Rasmussen, did at IFAI’s Smart Fabrics Summit in Washington, D.C.

In his overview of the smart fabrics market, Rasmussen said that smart fabrics are materials or structures that can sense environmental conditions or stimuli. The stimuli or the response could be thermal, chemical, electrical, UV light radiation (solar), piezo-resistive or pressure applied from another source. As part of an interactive textile system, smart fabrics may be found in markets as diverse as transportation, wearables, geosynthetics for infrastructure, health care products and, of course, sportswear and safety gear.

Leading markets

Perhaps because of their usefulness in so many discrete market areas, smart fabric products have shown consistent growth rates in consumption worldwide—from $1.6 billion (US) in 2014 to a projected $3.1 billion in 2018. Growth in the United States is comparable: at $700 million in 2014 to a projected $1.4 billion in 2018, averaging about 20 percent per year.

It’s interesting to note that four market segments share similar pieces of the worldwide sales pie, with transportation (largely inflatable seat belts and heated seats) leading at 27 percent. Military and government use follows with 21 percent, industrial and commercial products with 20 percent, and sports and fitness with 17 percent of smart fabric sales. The medical and health care segment has 8 percent; fashion and entertainment is close behind with 7 percent. These market segments represent a variety of end products, but often share technologies such as sensors and monitoring for athletes, heart patients, soldiers and industrial workers.

Serving the military

The U.S. military has been one of this market’s drivers, pushing R&D in multiple areas.

Nanotechnology-enabled smart fabrics have become the foundation for advanced smart textiles in various military applications, including military clothing or shelters for troops and equipment. One example is the HEROES (Harnessing Emerging Research Opportunities to Empower Soldiers) program, a collaborative effort between the University of Massachusetts–Lowell and The U.S. Army Natick Soldier Research, Development and Engineering Center (NSRDEC). The program has produced advanced nanotechnologies that include coatings that repel a range of liquids, including toxic industrial chemicals and chemical warfare agents.

The U.S. Army continues to invest in research that will provide soldiers with better protection, but also with less weight. The NSRDEC has developed the Torso and Extremities Protection (TEP) system, which will be available to soldiers in 2019. The TEP system features better soldier torso protection while reducing weight to 23 pounds, an improvement of about eight pounds on average.

The Army’s Ballistic Combat Shirt is an even bigger change for soldiers, providing ballistic protection to arms, necks and upper torsos. The Army is also developing new ballistic plates with a smart sensor to increase protection while reducing total weight even more. Wearable solar power capabilities and

energy-harvesting devices for uniforms are under continuing research and development, as are biometric monitoring capabilities.

The U.S. military has protective gear for warfighters under the threat of biological or chemical attacks, but it’s big, heavy and hot to wear, and can be worn only one to two hours before physical abilities are greatly diminished.

The U.S. Army and researchers from the Massachusetts Institute of Technology (MIT), the University of California, Santa Barbara, and the Air Force Civil Engineering Center are working on a prototype chem-bio protective uniform called “second skin,” which is a protective fabric designed with a textile substrate that uses responsive polymer gels. The fabric will be able to sense chem-bio agents and subsequently cause the gels to swell—closing the pores of the textile and keeping the dangerous agents out. Once the threat has passed, the second skin returns to its normal state.

Solar-powered fabric is of interest to the military as a way to reduce the weight from batteries needed to power the equipment that warfighters carry.

Thermal regulation

Colorado-based Outlast® Technologies developed a phase-changing technology that was originally developed for NASA to regulate the body temperatures of astronauts. It uses phase-change materials (PCMs) that absorb, store and release heat to provide the user thermal comfort. Outlast PCMs are microencapsulated and protected in a polymer shell named Thermocules™.

Body armor supplier U.S. Armor, based in Santa Fe Springs, Calif., incorporated Thermocules into the fabric used in the body armor it provides for police officers, Outlast Outer Carrier. Because officers are more comfortable in the armor, they are also more likely to wear it.

New York-based Ralph Lauren Co. developed a parka that uses a heat-conducting ink from DuPont to generate warmth like an electric blanket. The U.S. team wore the parkas at the opening and closing ceremonies of the 2018 Winter Olympics. An American flag on the interior back panel contains the carbon and silver ink, printed onto the jacket lining, creating a flexible fabric to heat the jacket. A thin power cord runs from the back panel to the right side front pocket that holds cords and a removable, rechargeable battery pack with controllable heat settings. When fully charged, the jacket stores up to 11 hours of heating time.

Smart sensoring

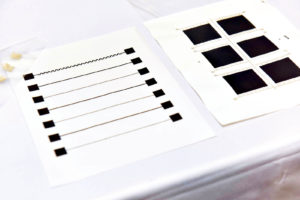

Berkeley, Calif.-based BeBop Sensors uses co- designed proprietary Eeonyx smart fabrics to create sensor solutions for OEMs—providing high-resolution, real-time force- and location-specific impact information. The company’s Smart Helmet Sensor System employs more than 40 flexible fabric sensors embedded in the helmet liner. The helmet scans the user’s skull 400 times per second, recording and storing multiple impacts in real-time, using a Bluetooth® connection for data transmission and commands to first responders.

The fitness market was an early adopter of sensoring wearables. Several companies have commercialized smart fabric products that monitor vital signs in babies, fitness enthusiasts and professional athletes.

A University of Rhode Island biomedical engineering team has developed smart gloves embedded with sensors on the thumb and fingers that measure tremors and rigidity, which are common symptoms of Parkinson’s disease. The gloves are connected to smartphones, which process the data and deliver it to the patient’s neurologist. This helps the doctor to better manage day-to-day treatment, and gives the patient the option of receiving health care while remaining at home.

Cleaning services

Researchers at Australia’s Royal Melbourne Institute of Technology (RMIT) are developing a new technology that grows copper and silver-based nanostructures on fabric, which cleans it when exposed to light. The hot electrons created release a burst of energy that enables the nanostructures to dissolve organic matter.

Stains from natural sources, such as a grass stain, could be eradicated on these fabrics, although non-organic stains such as ink might not come out. The challenge for researchers has been how to build these nanostructures on an industrial scale and permanently attach them to textiles.

Industry collaborations

For smart fabrics to continue to mature into a robust and reliable industry, standards need to be developed and applied. There has been a great deal of discussion in recent months, and a number of American organizations are cooperating on developing standards for e-textiles, including: The Association Connecting Electronics Industries (IPC), the American Section of the International Association for Testing Materials (ASTM) and the American Association of Textile Chemists and Colorists (AATCC). Similar efforts are underway in Europe, with a number of educational and research institutions, testing organizations and relevant companies participating.

Among the concerns are defining the quality of smart textiles, especially after repeated laundering; and quantifying end-use applications that can guarantee outcomes, such as assessing the accuracy and reliability of vital sign results in medical or fitness smart fabric applications. Developers are also looking at how to contain costs and expand the availability of electronics designed for use in textiles.

The MIT-led Advanced Functional Fabrics of America (AFFOA) consortium was formed in April 2016 and includes 89 universities, manufacturers and nonprofits. AFFOA won a competitive bidding process to lead a new manufacturing innovation institute in partnership with the Department of Defense. Called the Revolutionary Fibers and Textiles Manufacturing Innovation Institute (RFTMII), it brings together nontraditional partners combining fibers and yarns with integrated circuits, LEDs, solar cells and other capabilities to create fabrics that can sense, communicate, store energy, regulate temperature, monitor health and change color, among other possibilities.

The expectation is that, on one hand, internet-hungry younger users want connectivity, speed and communication options, while an aging population, in particular, will benefit from wearable technology with sensors that monitor well-being.

With new technologies and applications leading us in new directions, it will require diligent attention to appropriate standards to ensure that future populations will continue to benefit from this developing market.

Janet Preus is senior editor of Advanced Textiles Source and a regular contributor to Specialty Fabrics Review.

The key to moving smart fabrics forward is to “convert everyday textiles to bring new experiences in our lives by embedding technology in textiles,” says Dr. Qaizar Hassonjee, president of Hass Tech Associates LLC. Small smart fabric startups need:

• A plan focusing on the end-user experience;

• insights and domain expertise to create the experience; and

• the sensors/data/analytics to develop the insights.

Dr. Hassonjee was a featured speaker at the second Smart Fabrics Summit, held on April 14, 2018, in Washington, D.C.

TEXTILES.ORG

TEXTILES.ORG