By Paul Johnson

As a world leader in the manufacture of marine, awning and outdoor fabrics, Parà Group makes a wide range of products for iconic brands, such as Ralph Lauren Home, Fendi Home and Missoni. Five state-of-the art factories in Northern Italy produce more than 33,000 pounds of yarn and 32,000 feet of fabric every day. Even with such production capacity and global business success, the company has not lost sight of its environmental goals. Instead, Parà has dedicated itself to energy efficiency and ecological stewardship through water reclamation, solar power and cogeneration of power.

Parà goes beyond the current standards in energy efficiency and sustainable ecological programs. Under its “Respect for the Planet” initiatives, it employs a variety of measures to conserve energy and preserve the environment. According to CEO and managing partner Marco Parravicini, “Energy savings and respect for the environment have always been a priority for Parà. Our production water recycling plant was built 40 years ago, and the cogeneration plant for the production of electricity and steam was built 20 years ago.”

At its Pontirolo manufacturing facility, a modern cogeneration power station recovers and harnesses previously produced power for greater efficiency. Methane gas powers three 8-cycle endothermic engines that produce electric and steam power for the factory, and steam from the manufacturing process and engine emissions are recaptured and then utilized. The process is much more efficient than a conventional production of electric and thermal powerplant. “This plant is made up of three giant Caterpillar engines, which, thanks to the use of methane gas, are able to produce 4 megawatts of electricity each day,” says Parravicini.

In addition to the cogeneration power station, Parà has heavily invested in solar panels as a sustainable and eco-friendly source of power. More than 215,000 square feet of photovoltaic panels have been installed on the factory roofs at the Pontirolo plant and at its headquarters in Sovico. The solar cells produce about 1,000 kilowatts of electricity to further reduce the carbon footprint. “The main objective was to create a production plant that respects the surrounding environment and secondly that of making our factory efficient and competitive in terms of energy costs,” says Parravicini.

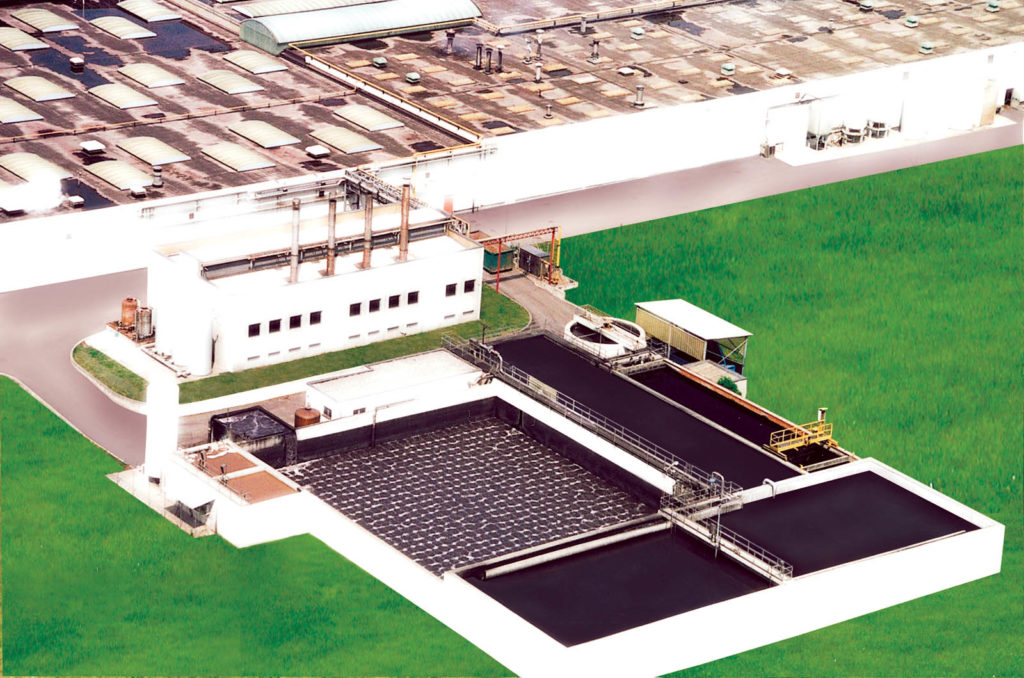

But energy efficiency isn’t the only priority for Parà. The company also invested in an advanced single-stage wastewater treatment plant at Pontirolo. About 530,000 gallons of water are treated per day, and it produces a 94 percent clean water yield. The system uses a variety of processes, and nitrogen-based compounds purify the water. This water reclamation program has greatly benefitted local farmers. “Our water cleaning plant allows us to completely clean the water used during the production phases,” says Parravicini. “These waters can be used for the irrigation of the surrounding fields that are used for agriculture.”

Parà consistently searches for intelligent ways to innovate, conserve energy and implement environmentally friendly production methods because environmental standards keep increasing and more carbon savings are necessary. “It is difficult to predict what will happen in the next 10 years,” Parravicini says, “but you can bet that Parà will be ready to invest in new technologies in this sector.”

Paul Johnson is a writer based in Minnesota.

TEXTILES.ORG

TEXTILES.ORG