Technological advances in the medical field are nothing short of mind-blowing.

by Pamela Mills-Senn

Take operating room (OR) technology. In today’s ORs, one might find an array of smart surgical tools, augmented reality devices and precision robotics that assist surgeons in performing the most complex and exacting of procedures. Patients are greatly benefiting from these advancements, but this isn’t the only medical area where technology is making a significant difference in terms of health, comfort and even outcomes. The consumer medical products arena is also seeing an impressive amount of innovation. For example, there are smart fabrics and textiles that incorporate sensing elements that can help wearers measure various physiological/biometric activity. Other materials are designed to capture and/or generate energy either kinetically, as the wearer moves, or by some other means. One such technology is offered by Santa Monica, Calif.-based Hologenix LLC, provider of Celliant® minerals.

Cofounded in 2002 by Seth Casden and David Horinek (inventor of the technology), Celliant was inspired by the understanding that the body is an energy source and that energy, or heat, can be harnessed. As Casden, CEO of Hologenix, explains, this insight came about while Horinek was researching treatment modalities for his grandmother, who had various physical issues, causing him to become intrigued by the wellness potential offered by infrared light.

Infrared light acts like a vasodilator, stimulating the mitochondria in the cells, promoting local circulation, improving cell and tissue oxygenation, and enhancing energy production, says Casden. It’s commonly used as a therapeutic treatment for maladies such as high blood pressure, congestive heart failure, rheumatoid arthritis and muscle tears.

“Energy is generated in every cell individually, requiring oxygen to do so,” he continues. “IR energy enhances the transportation and delivery of the oxygen from the blood to the cells. Celliant is able to address the significant inefficiencies in the human machine by recycling and converting radiant body heat into infrared energy, sending it back into the tissues and muscles, resulting in increased tissue oxygenation.”

(Increased blood flow/circulation is known to offer an array of benefits, like increased energy and stamina, faster recovery, a more restful sleep, and enhanced speed, endurance and performance, says Casden.)

Celliant has miniaturized the minerals that absorb heat and give off infrared light—the technology utilizes ceramic-based minerals like titanium dioxide, silica and aluminum oxide, among others—incorporating them into polyester while that material is in its liquid form. Once extruded into fiber, the Celliant mineral additive is embedded, becoming part of the fiber and lasting for the fiber’s lifetime.

Hologenix received a determination from the FDA that Celliant is a medical device and general wellness product with the intended use to improve local circulation. Nine clinical tests, including a recent study on over 150 subjects, demonstrated that Celliant increased tissue oxygenation by more than 8 percent after 90 minutes, says Casden.

The minerals can be added to nylon and then blended with other materials such as wool, cotton, Lycra® and Tencel™. The company is also working on incorporating it into additional fibers such as bamboo, says Casden. The technology is licensed to manufacturers—such as a garment company for example—who would purchase the raw material from Celliant’s approved supply chain. Textile applications include health care products, apparel, bedding and items used in veterinarian markets.

Rapid change ahead

As a contract manufacturer making products for a spectrum of industries, Don Alhanati, founder and CEO of CustomFab USA, says that of necessity the company stays well in front of the trends. Located in Garden Grove, Calif., CustomFab is a sewing contractor and soft goods manufacturer for well-known brands in the military, aerospace, sporting goods, pet and luggage industries, as well as in the medical industries, for which the company makes orthopedic devices, patient lifting slings, pediatric care products, CPAP equipment, tracheostomy straps and other products. CustomFab manufactures products from start to finish, says Alhanati.

“One trend we’re seeing is an advancement towards utilizing 3D knitted fabrics on medical products that incorporate tech into the knitting and can monitor a variety of different vitals,” he says. “It’s exciting because suddenly fabrics are changing more rapidly than before, encouraging us to keep our technology up to speed with their innovation.”

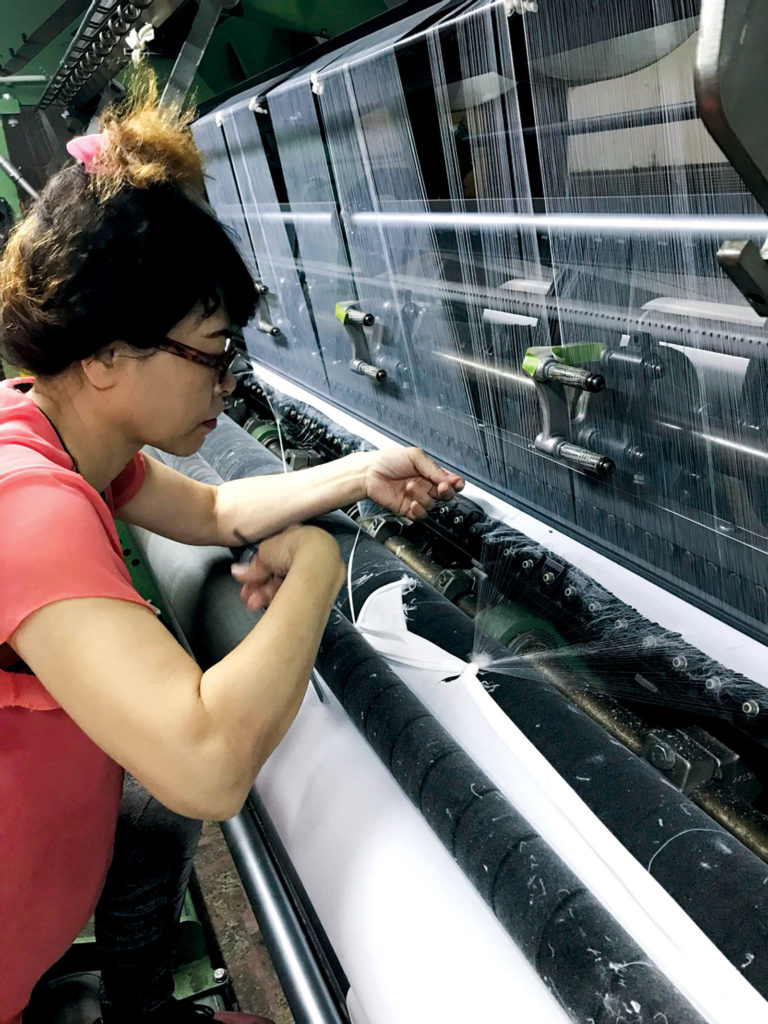

Inlay technology, along with tension control and positive feeding devices, has also helped spur innovation in soft-good knitted products, says Martin Legner, head of product management, Technical Textile Applications, for H. Stoll AG & Co. KG. Headquartered in Reutlingen, Germany, Stoll makes relevant flat-knitting machines used in the production of soft medical goods, says Legner.

“We are involved in product developments along with customers or start technology and product improvements based on machine or accessory optimization,” he explains. “Major product categories are orthopedic/optimal fit supports such as knee, ankle, elbow and wrist braces as well as back support systems; custom-fit compression garments to treat venous insufficiency, scar reduction, lymphedema and other treatments; specifically made wound dressings; gel liner sock and prosthetic stockings; and medical implants.”

Consider orthopedic supports. These are made on a flat-knit machine in order to conform to anatomic shapes, and have designed-in “function zones” constructed to allow more or less pressure as required. Breathability is placed across the product where specifically needed, Legner says. Nylon is used as the material base and is plated with spandex to allow for stretch, along with a highly elastic inlay thread. Attention is paid to fashion and styling with applied jacquard and structure variations adding to the appeal and function.

Compression garments are just as complex. Because they’re designed to “generate very high compression rates,” they need to be knitted to the wearer’s body measurements, with their construction similar to that of

orthopedic supports.

“However, the mass customization production method makes every product an individual order,” Legner says. “As such, you need a corresponding automated production line allowing such specific products to be made and shipped to the patient within 24 hours. For those suffering from relevant diseases, wearing such items is a must-do in parallel to their compression therapy.”

Inspiring new thinking

Legner expects demand for orthopedic support, compression products and similar solutions will grow, particularly as obesity continues to be an issue, and as people age (also potentially becoming sicker and more overweight). For example, he explains, too much weight can stress the joints, causing wear and tear. Advancing age is often accompanied by arthritis. Both conditions can increase the need for orthopedic support. And certain cancers and cancer treatments may necessitate the use of compression garments.

“The majority of such products are nowadays being used for the treatment of lymphedema,” Legner explains. “Lymphedema can be inherited or the result of a cancer treatment, for example, where the lymphatic nodes have to be removed, causing the lymphatic system to have problems. The circulation collapses and the consequence is the need for compression therapy.”

Lipedema, a condition in which fat is distributed in an irregular way underneath the skin, typically in the buttocks and legs but also in the trunk of the body and arms, often requires compression therapy, Legner adds.

Staying on top of textile advances is essential, says Alhanati, mentioning that CustomFab is seeing smart fabrics with cooling technology or those with high-puncture/cut resistance and break strength. These enhanced properties demand and inspire new ways of thinking when working on projects, he says. Fabric technology is also innovating in response, demanding more of manufacturers as well.

“We have to stay educated and knowledgeable,” says Alhanati. “Fabrics have traditionally been relatively low-tech in terms of the processes involved to use them in production, but now as they progress, manufacturers have to evolve in order to take advantage of these advancements.

“Consequently, the R&D process becomes more intricate and drawn out,” he continues. “The equipment required is specialized and expensive. Subsequently, we find ourselves needing to hire employees with skills not previously required, and having to create the corporate infrastructure to support them.”

Alhanati believes the years ahead will bring some exciting new products, marrying technology with medical care and rehabilitation, providing consumers with more options, more information and greater control over their health care and quality of life. Legner is equally optimistic about the medical products market.

“There are always product improvements, variations and embellishments on their way,” he says. “These ensure the survival of our machine customers and help to improve the life status of patients living with really serious diseases.”

Pamela Mills-Senn is a freelance writer based in Long Beach, Calif.

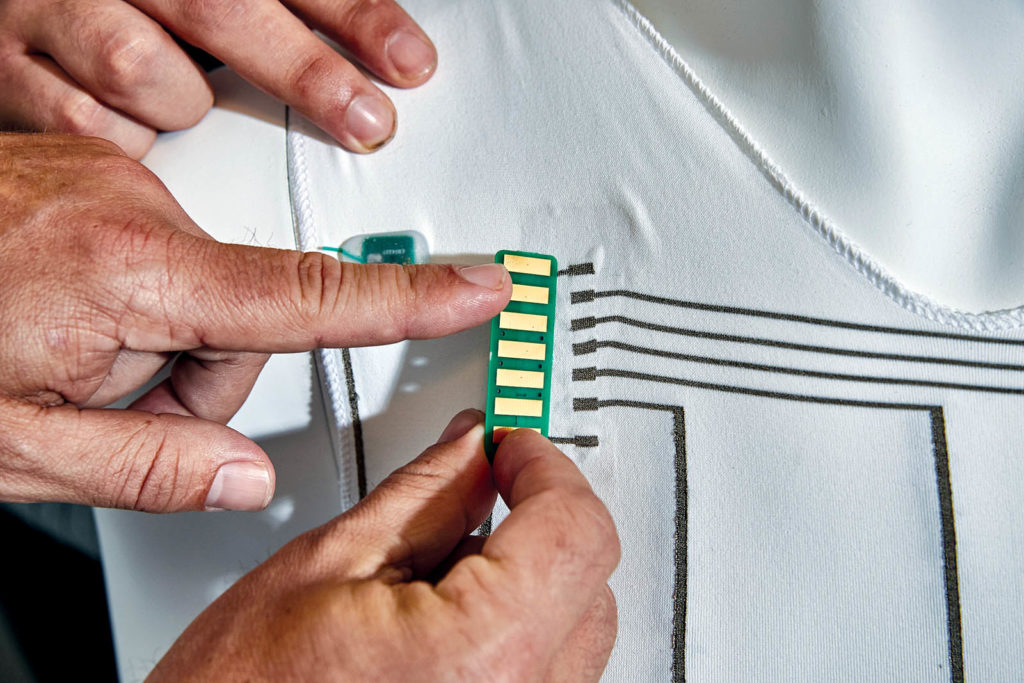

Professor Trisha L. Andrew is associate professor of chemistry and chemical engineering at UMass Amherst. Some of the research being conducted involves smart apparel embedded with self-powered sensors that can turn ordinary clothing into monitoring devices or portable power sources. The challenge is to integrate these features inconspicuously into the clothing without negatively affecting how the clothes look, feel and function, says Andrew.

“Our lab uses reactive vapor coating to transform commonly available, mass-produced fabrics, threads or premade garments into a plethora of comfortable, wearable electronic devices by directly coating them with uniform and conformal films of electronically active conjugated polymers,” she explains. “We’ve used vapor-coated fabrics as electrodes for monitoring heart rates, respiration, joint motion/flexibility, gait and sleep posture.”

Vapor-deposited electronic polymer films offer several advantages, such as being wash-and-wear stable and having the capability of withstanding demanding textile manufacturing processes—qualities that have enabled the lab to create self-powered garments by using sewing, weaving, knitting or embroidery procedures, generating “sensitive and reliable data,” Andrew says.

Ohmatex A/S, headquartered in Aarhus, Denmark, was founded in 2004 with the objective of “commercializing research developments and technologies in smart textiles and wearable electronics,” says Christian Dalsgaard, CTO and founder.

“We integrate electronics in a variety of fabric materials based on synthetic fibers (nylon, polyester and acrylic), natural fibers (cotton, etc.), and elastic fibers (elastane),” Dalsgaard says. “The electronics are incorporated into socks, training tights, T-shirts, gloves and sleeves. The reason for integrating textiles is to improve the accuracy of the vital signs, such as skin temperature, pulse and respiration. Another reason is to raise the comfort level for the user and to avoid wiring and adhesive electrodes.”

The company has integrated electronics with textiles for a wide variety of applications, creating wearable physiological monitoring systems, primarily for the medical/health care and sports markets. Ohmatex also has a contract with the European Space Agency to track exercise efficiency on the International Space Station.

TEXTILES.ORG

TEXTILES.ORG