The International Achievement Awards (IAAs) began in 1946 as a photo contest for awning and canopy projects, and 75 years later, the program continues to honor exceptional work in those fields. But as we celebrate the 75th anniversary of the IAAs in 2021, we can marvel at the wide range of projects that use specialty fabrics, including aerospace applications. From spacesuits to parachutes, high-tech fabrics help humanity explore the universe.

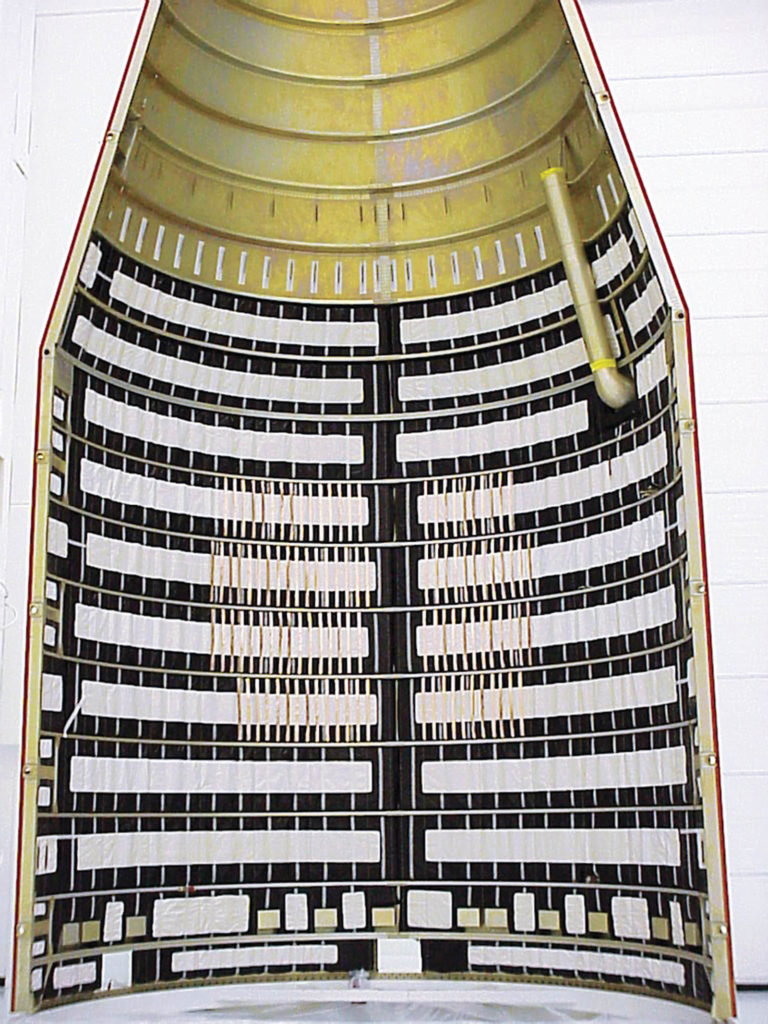

One example is this 2017 IAA Outstanding Achievement Award winning project from AR Tech of Fontana, Calif. These blankets are used to line the inside of the nose cone, referred to as the PayLoad Fairing (PLF), of a space launch vehicle. They provide sound absorption and vibration reduction, static bleed-off with carbon Teflon™ cover material, and ensure that particles from the interior of the blankets do not contaminate the satellite by use of the stainless steel fabric filtration medium, which also allows the blankets to expel interior pressure during the launch. There are about 40 blankets per launch. During the launch process, the rocket experiences extremely high temperatures and vibrations, and the PLF blankets provide protection for the satellite during this process. AR Tech has crafted thousands of these custom PLF/acoustic blankets for various launch vehicles since the 1990s. When the client changed one of the key elements of the raw materials, AR Tech faced significant challenges during manufacturing. The first set was delivered to the customer ahead of schedule and passed with 100 percent quality.

Project management: AR Tech, a division of A&R Tarpaulins Inc., Fontana, Calif.

Project manager: Jessica Foley

Fabric: MD3 CTR from Saint-Gobain Technical Fabrics

TEXTILES.ORG

TEXTILES.ORG