Supply chain traceability and transparency are increasingly important to hold various entities, such as brands and product manufacturers, accountable for the claims they make.

This pressure isn’t just coming from governments in the European Union, the U.S. and other countries that have enacted legislation and regulations around forced labor/unethical practices, explains MeiLin Wan of DNA Sciences Inc. It’s also being driven by media and consumer scrutiny, particularly as it concerns sustainability and false or misleading environmental claims around a product, or greenwashing.

Wan—vice president, textile sales for Applied DNA Sciences, a Stony Brook, N.Y., company facilitating supply chain transparency and sustainable processes—says that brands and their manufacturing partners are increasingly expected to prove their products and the supply chain are “compliant from source to shelf.”

This is especially critical within the garment and footwear industries, says Lily Pang, business manager at SGS Hong Kong Ltd. A testing, inspection and certification company with global headquarters in Geneva, Switzerland, SGS works in partnership with governments and industries to support “every tier of the supply chain,” says Pang.

“I would say supply chain traceability is at the top of most apparel and interior textile companies’ priority lists because consumers and regulators in places like the U.S. and EU are demanding it,” she explains. “True traceability in supply chains is the only way to answer concerns over ethical sourcing, environmental impact, quality control and supply chain resilience.”

This article explores some of the current solutions for making supply chains more traceable and therefore more transparent and accountable.

Tagging technology

An “early pioneer” of molecular DNA textile tagging technology, Applied DNA has developed “unique and specific” synthetic tags, or “molecular barcodes,” capable of tagging billions of fibers, says Wan. Tagging is a very secure technology, she explains, because once misted onto the fiber, such as prior to being baled or during spinning, CertainT® tags adhere to it, allowing for verification of claims of authenticity, traceability and origin. The technology was originally used on cotton, but now it can tag other fabric surfaces, including leather with certain coatings.

“We also tag other products like sewing and embroidery thread using our molecular DNA and patented tracer technologies,” Wan says. “By tagging the product itself, you can be certain that you can prove it is your product in your supply chain for your brand.”

Wan says Applied DNA defines traceability as “knowing where, who, what, how and when” a product is made, from the source material to the end product.

“Why this is important is that as products are made, typically in factories in different countries and locations, there can be opportunities to substitute other fibers or materials that may be cheaper and/or obtained from different origins using unethical practices, such as forced labor,” she says. “Supply chain traceability tools, such as DNA tagging, genomic and isotope testing, can help supply chain manufacturers to verify—before, during and after the product is made—and in so doing, ensure that any claim is compliant and authentic.”

Recording every transaction

Headquartered in Malmö, Sweden, PaperTale Technologies is currently focusing on the textile and fashion industries with its blockchain technology, says Bilal Bhatti, CEO and cofounder, although its system can support supply chains across all industries.

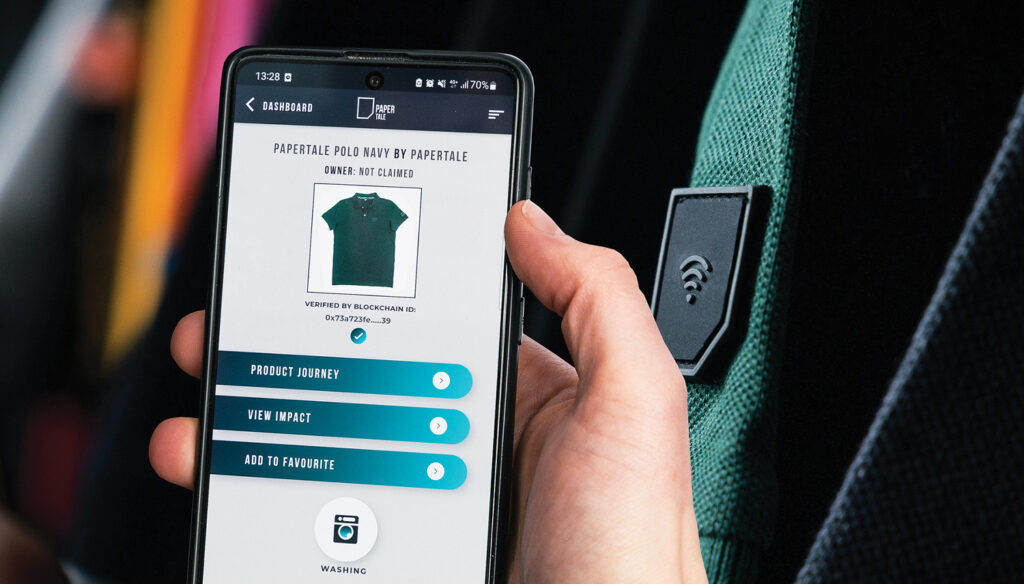

Bhatti says because his company’s solution integrates with existing enterprise resource planning and product life cycle management systems, factories and brands can monitor and validate material flows, along with social and environmental data, in real time. Securely stored on a public blockchain, the data is accessible to all stakeholders, including consumers, who can scan a product’s near-field communication tag or QR code, which is activated after the product is complete. (Parties can still restrict access to sensitive data, affording a customizable degree of transparency.)

Bhatti explains blockchain technology:

- It’s a decentralized way of storing data, meaning transactions/data are validated by a community rather than being stored by one party. “When multiple parties record and validate data, it’s nearly impossible to change it. In this way, blockchain is a tool to offer proof of authenticity and quality,” he says.

- It provides a chronological record of every action associated with a product because data is recorded at each transfer of a product from one party to another.

- It can store programs, such as smart contracts, that automatically enforce an agreement’s terms and conditions. This can be used for all types of agreements.

“PaperTale uses blockchain technology by creating a digital duplicate or digital twin for each material,” Bhatti says. “When the physical material moves to the next party in the supply chain, the same action is mirrored in the digital realm. This transaction is recorded on the blockchain, along with confirmation from the receiving party.”

PaperTale also uses the technology to verify social impact claims by posting wage transactions along with worker confirmations that these wages align with their contracts.

“Environmental impact information can be captured … by using sensors that connect to the IoT [Internet of Things], which allows real-time data collection,” Bhatti says. Energy usage and indoor air pollution are examples. “Blockchain adds a layer of trust because the data can’t be changed afterwards.

“As we look to the future, more advancements can be made to ensure the data on the blockchain represents real-life events,” he continues. “Additionally, education about blockchain technology will need to advance in order for the technology

to do the same.”

Collaborative traceability

SGS has partnered with FibreTrace®, a Singapore-based company, to develop SGS’s Fiber Integrity Protocol. “Key to our system is the application of FibreTrace’s patented luminescent pigment to fibers,” she explains. It’s done at the ginning or spinning stage or, for rPET [recycled PET], at the master batch stage. “This contains a unique signature that records product type and provenance, which can then be tracked and verified along the entire supply chain using a specialized scanner. Data from these scans is sent back to a blockchain-powered platform, enabling real-time supply chain insights.”

The company also supports the technology by “reviewing compliancy and traceability” before the pigment’s application—for example at polyester recycling collection points.

Blockchain technology is central to SGS’ Fiber Integrity Protocol transparency solution. “It provides the security you need to record product information, relevant certification documents, orders or shipping documentation. It allows each product to be tracked as it progresses through the supply chain, wherever it goes in the world,” Pang explains.

There are many issues affecting supply chain traceability that need addressing, says Pang, including data security and privacy, the complexity of the global supply chain, consumer education, the challenges faced by small suppliers, and better alignment with government regulations.

“Innovations such as blockchain technology, IoT integration and AI- [artificial intelligence-] driven analytics are a way forward,” she says. “And they are poised to revolutionize traceability in our supply chains, putting the power to control back into the hands of brands and retailers.”

Pamela Mills-Senn is a freelance writer based in Seal Beach, Calif.

SIDEBAR: A new, Better Cotton solution

Responding to ever-increasing regulations and laws requiring greater supply chain transparency and traceability, Better Cotton launched its traceability solution in November 2023, after three years of development.

“There is increasing demand from consumers and consumer rights authorities due to concerns about greenwashing,” says Alia Malik, chief development officer for the organization, citing another reason for the transparency efforts. “Consumers have a right to know where and in what conditions the products they purchase have been made in order to make informed purchasing decisions.”

The traceability solution, which will have stakeholders all along the supply chain logging transactions, also supports Better Cotton’s efforts to improve the livelihoods of those in cotton farming communities, says Malik.

“Making cotton traceable would also allow cotton farmers, suppliers and manufacturers to continue accessing increasingly regulated international markets and provide brands and retailers with more information about their supply chains,” she says. “It would also create opportunities around farmer financing mechanisms.”

Accounting for more than one-fifth of global cotton production and headquartered in Geneva, Switzerland, Better Cotton “is the world’s leading sustainability initiative for cotton,” she says. Currently, crops following Better Cotton’s principles and criteria are grown in 22 countries worldwide, including the U.S., with the organization’s approximately 2.2 million licensed farmers producing 5.4 million metric tonnes (nearly 6 million U.S. tons) as of 2022–23.

TEXTILES.ORG

TEXTILES.ORG