It’s a fertile time for next-generation biofabrics, and the environmental impact of the textile industry is a huge driver for entrepreneurs searching for answers to the textile waste problem. Many young companies’ materials scientists are working to bring natural, biodegradable solutions to the market and have reimagined the entire textile life cycle, from raw materials through to the final product’s end of life.

More than $3 billion has been invested in next-generation materials companies in the last 10 years, says the state of the market report by the Material Innovation Initiative. The market area hasn’t yet reached maturity, with established best practices and methodologies and full integration of scaled products into the greater supply chain. It’s still an area full of innovation, challenges, improvements, consolidation, feedback, and lessons learned. Collaboration between textile companies and brands is essential to continued advancements. Feedback and dialogue can help lead innovators to further refinement and enhancement in their materials and achieve large-scale commercialization.

The companies featured this year in our spotlight on biofabrics represent a range: Some have a product in use, some are still in testing phases, some are in the process of scaling up and others are in full production. Their fibers and fabrics are made from materials including plants, fungi, fermented sugars and even seafood waste. The companies’ holistic view considers how textiles fit in the planet’s entire ecosystem, and their new biofabrics are edging their way into fashion and other sectors like furnishings, automotive textiles and more.

TômTex: Where “waste is the new luxury”

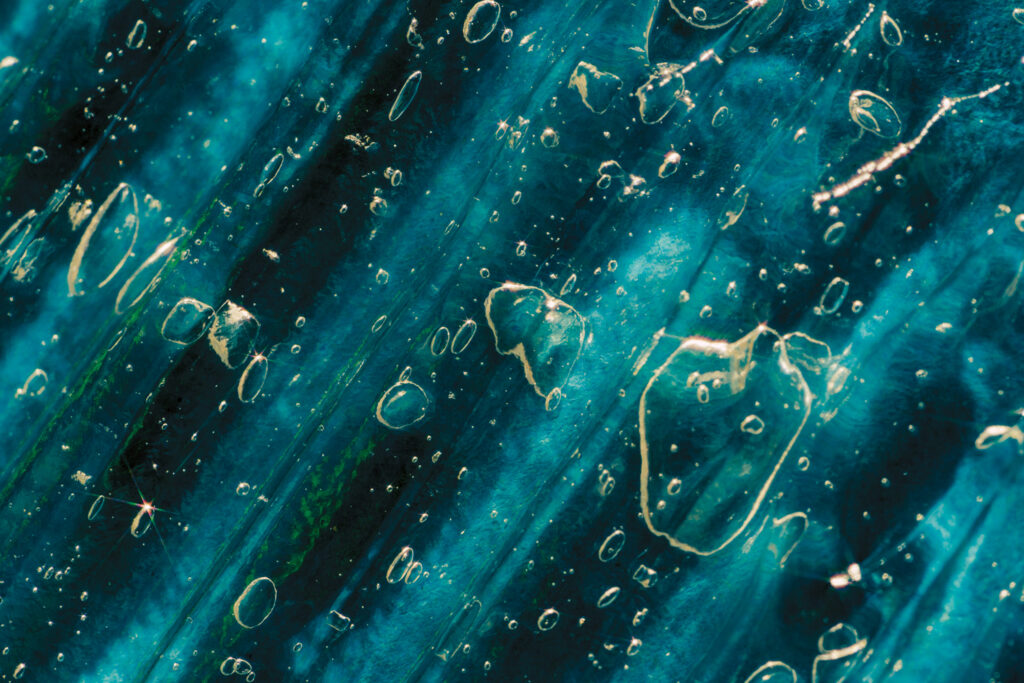

In Brooklyn, N.Y., three-year-old startup TômTex is on a mission to develop products that will be “truly good for people and the planet,” says Uyen Tran, its founder and CEO. TômTex creates biofabrics made from mushrooms (TômTex Series M) and seafood-shell waste (TômTex Series WS™). Although the company’s products are still in testing, Tran and her team are optimistic about their leather-alternative fabrics that are both 100% bio-based and biodegradable and do not contain plastics, caustic chemicals or toxins.

Through Tran’s experience with the fashion industry, she identified its waste as a prime contributor to environmental degradation. This contrasted with practices in Da Nang, Vietnam, where she grew up. There, people believed in fixing broken things and keeping items that still served a purpose. Those core values guided her work to create alternative fabrics that follow a one-of-a-kind circular and bio-based design that includes water-based green chemistry.

“The whole innovative material industry is very new,” Tran says. “The complex process uses science, not magic, and requires time to develop.” The timeline from research and development to full-scale production can be years long.

Mushrooms and seafood-shell waste provide chitosan, a water-soluble polymer. According to Tran, TômTex is one of the first to create fabric using that material, which the company responsibly sources from Vietnam and around the world. TômTex biofabrics are water-resistant and nonflammable. The production process does not include tannins and has a small carbon footprint.

“TômTex allows nature to guide its work by investing in simple, regeneratively focused ideas. We allow the source materials to lead us.”

The optimal use now for TômTex’s Series M and Series WS is in small goods like shoes and handbags. In time, Tran expects the company’s materials will be ready for use in home furniture and decor and the automotive industry. She invites brands to contact her to explore opportunities to use TômTex fabrics.

“Engagement with brands, with information exchange and feedback for us is valuable,” says Tran. It can inform how both the developer and the brand move forward to bring biofabrics to a commercial scale.

Bananatex: “A textile (r)evolution”

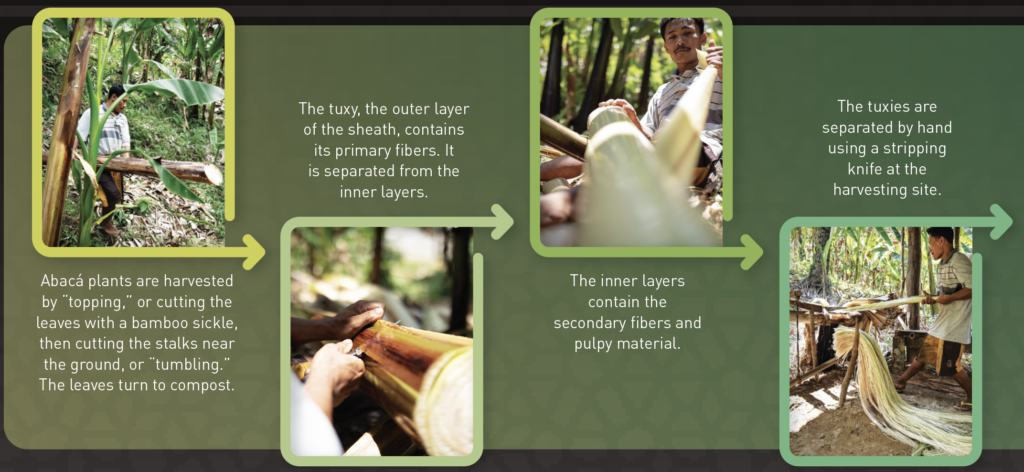

According to Hannes Schoenegger, co-founder/CEO of Bananatex® in Zug, Switzerland, abacá banana plants have the “strongest plant fiber in the world.” He says it has been used for years to make everything from shipping ropes to tea bags.

The sturdy, self-sufficient abacá plants grow in the Philippine highlands (and elsewhere), within a natural ecosystem of sustainable mixed agriculture and forestry. They fully regenerate within one year after harvest and require no pesticides, fertilizer or extra water.

Schoenegger’s company QWSTION was established in 2008 in Zurich and is known for its bags and backpacks made primarily from cotton. Company leaders also explored using other natural fibers like hemp, bamboo and linen and then found the abacá banana fiber in 2015. They established Bananatex as a spinoff.

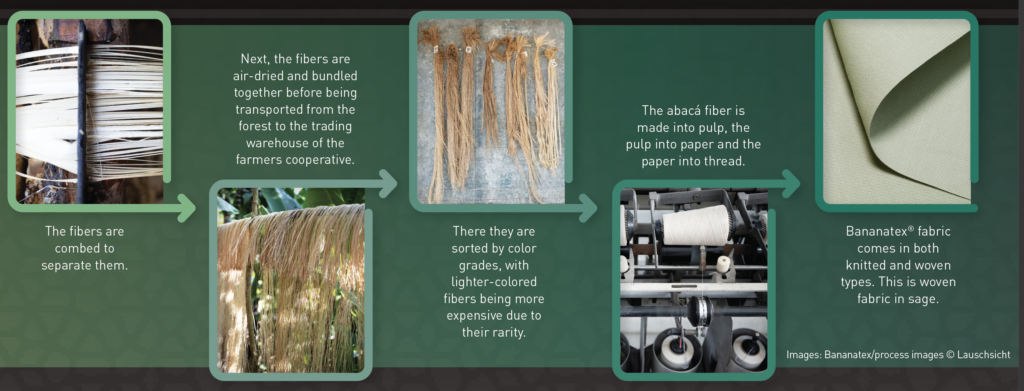

Creating fabric requires fine yarn. It took QWSTION three years to create one through a process that transforms the abacá fiber into pulp, the pulp into paper and the paper into thread. In late 2018, the company launched its first backpack with the new biodegradable Bananatex fabric. It also has a fully plant-based wax coating for water repellency.

“Our fabric is a replacement for polyester or fossil fuel-based products, although it’s not a leather replacement,” says Schoenegger. “And it is twice the price of organic cotton, which is a bottleneck.”

Extensive manual labor to gather and transform the fiber increases its cost. But the crop also has significant value. Abacá plants enhance the economic prosperity of the farmers and contribute to reforestation in areas where monocultural palm plantations once caused soil damage. The plant’s leaves remain on the ground after harvest to decompose and create natural fertilizer.

Bananatex’s process avoids creating waste in all parts of production and the product life cycle. Cradle to Cradle Certified® Gold by the Cradle to Cradle Products Innovation Institute, Bananatex has third-party affirmation of its commitment to protect the natural environment and support its communities.

Bananatex is used in the furnishings, automotive, fashion and footwear sectors. While in some cases brands have needed to make small adjustments, such as how to sew a specific line or put buttons on a new textile, existing facilities have been able to work with Bananatex as is, says Schoenegger. “A shoe by H&M in 2022 sold out in two hours, thanks in part to a large communications effort.”

Keel Labs: “Harnessing the power of the ocean”

Working in the fashion industry showed Aleks Gosiewski and Tessa Callaghan two challenges brands faced when sourcing sustainable materials: There weren’t many available, and those that were did not readily fit into brands’ established supply chains or production infrastructures. The duo co-founded AlgiKnit in 2017, which became Keel Labs in 2022, based in Morrisville, N.C. Gosiewski is the chief operating officer and Callaghan is CEO.

“We set out to solve both problems with a product that lowers the industry’s environmental footprint, implements directly into the industry’s existing supply chain, is easily scalable by utilizing widely available raw materials and retains the familiarity and desirability of natural fibers,” says Anuradha Gupta, senior manager, process and product development. “We developed Kelsun™ fiber, a material made from seaweed that is a plug-and-play solution for textile suppliers, meaning production requires no new equipment or machinery.”

Kelsun fiber, made from more than 75% kelp, looks, feels and performs like cotton and viscose. Keel Labs’ proprietary blend of naturally sourced additives that improve inherent properties of seaweed polymers makes up the remaining 25%.

Seaweed, according to Keel Labs, is one of the world’s most regenerative and carbon-sequestering organisms. Compared to cotton, Kelsun uses 70 times less water and 100% less agricultural land and pesticides, the company notes. Extensive vetting of its suppliers ensures the sourced seaweed (whether farmed or wild-sourced) is sustainably harvested. As the company’s production scales, it is actively exploring a range of sources for seaweed biopolymers. Its leaders look to the scientists, processors and academics at the forefront of this movement to bring the best solutions for people and the planet alike.

“It has been exciting to see the potential of nature-based solutions to transform how products are being made with Kelsun,” says Gupta.

In late January 2024, Keel Labs produced a sample jersey-knit pocket T-shirt with 70% Kelsun fiber and 30% cotton, demonstrating the first garment made with it on existing industry-standard machines. Callaghan calls the T-shirt “a massive milestone.” The company began developing Kelsun fiber six years ago and has concentrated on scalability for two years. With the shirt, it has demonstrated that Kelsun can be used outside the luxury industry and can apply to any wardrobe. The achievement will help further commercialize the product so that brands can integrate it into their existing supply chains.

Kelsun fiber shows promise for applications in home goods, furnishings, automotive, fashion and other sectors. Stella McCartney used it in her 2024 collection. “We are actively working to unlock new product and sustainability features,” Gupta says.

Spiber: “Weaving science and nature into a new material”

Kazuhide Sekiyama and Junichi Sugahara are both directors and representative executive officers in Spiber Inc., the company they co-founded in 2007 in Yamagata, Japan. It began as their university project around spider silk. The name Spiber is a combination of the words “spider” and “fiber” to reflect their goal to produce protein fibers with properties like natural spider silk has. Their work’s evolution led to the development of Spiber’s Brewed Protein™ material, which is made into fibers, yarn and fabric.

“Brewed Protein biomaterials can offer alternative solutions to a wide range of conventional animal-based, plant-based and synthetic materials for various purposes, including textile applications for the apparel industry,” says Sekiyama.

Manufactured through microbial fermentation (brewing), this new class of material relies on Spiber’s proprietary technology that enables customized design and molecular engineering of nature-inspired protein polymers. Sugarcane, sourced from Thailand, is Spiber’s primary fermentation feedstock for its lab-grown material. According to Spiber, Brewed Protein materials are breathable, soft and comfortable. Some worsted spinning processes can achieve a polished, lustrous surface and smooth touch. Some woolen spinning processes can achieve a hairy, cashmere or wool-like surface with a soft touch.

“We believe Brewed Protein materials can be manipulated to be more like silk or cashmere/wool in certain ways,” says Sekiyama. “Ultimately, the fiber is its own unique material that has properties similar to both silk and cashmere.”

Spiber is committed to sustainable agriculture practices and a future shift toward circular feedstocks. Breaking down agricultural waste like sugarcane bagasse could provide a way to upcycle and feed the microbes to produce Spiber biofabrics. Company testing demonstrates that a product made from 100% Brewed Protein fiber with chemical-free dyes could break down into nutrients and return to the biosphere when released into the environment.

Spiber is scaling up commercial production of its protein polymer to provide Brewed Protein materials to a broader range of mills and brands. With its existing production plant in Rayong Province, Thailand, and plans to open up another facility in Clinton, Iowa, in the coming years using corn-sourced dextrose, Spiber’s annual production capacity will increase several hundred tons. This expansion is in response to steady growth, and Spiber attributes that progress to its dedicated team and cooperation from stakeholders and investors.

“We have encountered challenges in overcoming technical constraints and securing funding,” says Sekiyama. “However, today we are actively working to lower costs by improving our production capacity.”

Linda “LW” McDonald is a freelance writer based in Minneapolis, Minn.

SIDEBAR: From forest to fabric

Abacá plants have several stalks that can be harvested annually and regenerate fully within a year.

SIDEBAR: BIOFABRICS By the numbers

From 2023 State of the Industry Report: Next-Gen Materials

144 next-gen (animal-free) materials companies (93 formed since 2014)

Replacement material

Number of companies creating:

- 92 leather

- 24 silk

- 16 wool

- 14 down

- 10 fur

Main input

53% plant-based (also includes fungi fruiting body and algae)

14% microbe-derived (cell culture, fermentation)

11% blends

10% recycled material

8% mycelium (fungi root system)

4% cultivated animal cells

Source: Material Innovation Initiative

TEXTILES.ORG

TEXTILES.ORG