Industrial Revolution 4.0 is here.

by Connie Huffa

Humans were born to learn and innovate. By nature, we constantly define, measure, analyze, improve and control our environments. Whether we know it or not, by wanting the latest and greatest we are changing not only how we make and buy things, but how we communicate our wants and needs.

To explain the next industrial revolution (Industry 4.0), let’s look at how the first three industrial revolutions changed our world by democratizing manufacturing, transportation, communication and consumerism, while also killing—and creating—jobs.

The First Industrial Revolution

In the 18th and 19th centuries, there was a shift from an agrarian economy to an industrial and urban way of life. Iron and textile industries grew with coal- and steam-powering factories. Cotton was king. Charles Darwin’s “survival of the fittest” suggested that the basis for organic evolution meant being “better designed for an immediate, local environment.” He surmised that DNA, the software of life, was adaptable and open to even the slightest change. One of the most common adaptations of an organism is symbiosis—when two organisms work together to better adapt to an environment. This means cooperation, not strength, is arguably the most “fit” of all traits for success. So, too, for humans and machines.

The Second Industrial Revolution

From about 1873 to right before WWI, adding electricity, steel and oil to manufacturing eliminated redundant tasks, such as the need for an individual weaver or knitter at each machine. Production became more consistent and repeatable as telephone communication, mass production and power-driven machines made it easier to measure productivity, control the manufacturing process and set best practices. A lot of weavers and knitters were out of day jobs, but electric lighting made shift work possible.

The first two industrial revolutions transferred populations and wealth from rural, local cottage industries to big cities. At the same time that farming equipment improved and farm jobs decreased, the city factories added jobs at an exponentially faster rate than farming lost them. Expensive items, once reserved for the elite, became more affordable and spread farther and faster than ever before.

WWII brought about changes in materials—plastics and polymers—unchaining the manufacturing world from the seasonal fiber production and variations of cotton, wool, linen, flax and hemp. Year-round manufacturing adapted nylon, rayon, acetate and polyesters into new and different products the world had never seen.

The Third Industrial Revolution

The 1960s-1980s added widespread use of computers to manufacturing, the personal computer, the internet, cell phones and aerospace. This period introduced improved strategies for manufacturing and communications between people and machinery, reducing labor-intensive processes and managing resources, components and the production floor including:

• JIT (just-in-time manufacturing—1970s)

• Kaizen (1985); the Japanese

word for “improvement”

• Six Sigma (1986), ISO 9001 (1987)

These systems rapidly improved manufacturing agility, profitability and competitive edge in working with demanding retailers, while also getting manufacturers closer to consumers and the pulse of buying trends. Internally, mills could rapidly connect production with in-the-moment sales data that the mechanical machinery did not have. Adding computers to textile machines:

• vastly expanded design capabilities

• reduced design time from days to hours

• eliminated redundant tasks

• allowed machines to be electronically calibrated

• removed human error and dependence on technicians

• streamlined technicians’ work

Basic electronics gave way to the digital age. Photoshop® was invented in 1988. Computer-aided design (CAD) systems gave designers and engineers creative control of their products beyond simple designs. Factories, which were vertical, could now be global. Factories that did not shift from mechanical to digital went the way of the buggy whip.

The 1990s brought us WYSIWYG (What You See Is What You Get), where CAD systems created manufacturing programs automatically. Why? Because China joined the World Trade Organization (WTO) and machine builders found themselves needing to sell and train entire workforces quickly. WYSIWYG became the new normal in manufacturing as fabrication shifted overseas and companies focused less on the technical aspects of making textiles and more on marketing and sales. Adapting to the pulse of the market has been key to many brands’ and manufacturers’ retail competitive advantages.

Just when global manufacturing seemed to be a well-oiled machine, something happened. In 2007 another revolution, smartphones, digitally connected what is now more than 2.1 billion mobile phone users. The internet has become the corner store, connecting buyers from every corner of the world, sellers of all sizes, and commerce in small and large transactions. Taking pictures, communicating, banking, shopping and doing business would never be the same again.

The Fourth Revolution is now

There is no going back now that we have entire generations who know only a time where life, including making and buying things, is done in real-time by browsing thousands of items from hundreds of places. In the value stream, free shipping has replaced feeling, touching and physically inspecting a product before making a purchase. It’s also difficult to turn back time on much of the textile knowledge that’s been lost over the past 25 years.

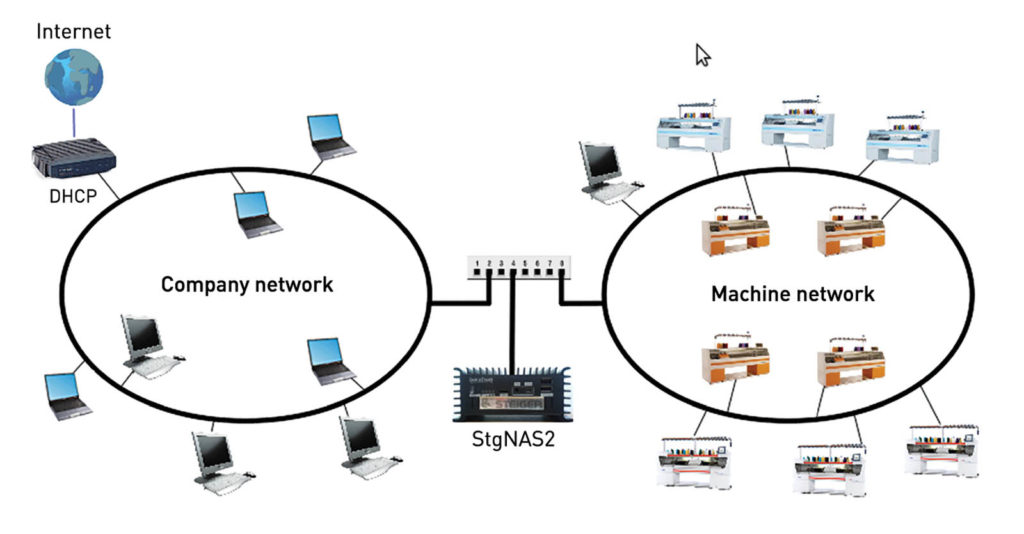

How are machine builders adapting to this market change and knowledge gap? They are creating full systems where a central platform gathers product design data and plans production, enabling the factory to control, plan and optimize its production with limited or no human action. The goal is increased productivity with computers doing complex calculations in minutes, unlike a person who may take hours or days and may make errors.

In the Fourth Industrial Revolution knowledge is truly power. Wealth is shifting from the tangible world to the virtual. The most valuable companies in the world are data collecting and distributing mega-companies. Industry 4.0 connects assets from big data, social influencers (marketing), customer information, and online interfaces to manufacturing and shipping.

Now it’s personal

The time between adapting new technology to delivering on our growing list of expectations is getting shorter, and the disruptions in our workforce are seismic, rather than gradual, as technology develops faster and faster. While we are trying to grasp digital manufacturing and Industry 4.0, we are also embarking on Industry 5.0—personalization. On-demand manufacturing. Made-for-me products.

Companies like Nike, Adidas, Ministry of Supply, Unmade, Ralph Lauren and others are making customized products on demand. As physical retailers struggle to create “shopping experiences,” Bloomingdales worked with Bodymetrics to body-scan customers. A customer’s measurements are then compared to the jeans measurements in stock to ensure the customer gets the perfect fit without having to try on anything. To meet expectations of instant gratification, getting what they want when they want it, consumers are trading privacy for convenience.

Manufacturing must adapt

Today, a product can be designed on a computer and “printed” on a 3D printer on the other side of the world. Makers everywhere should be asking:

• How might digitalization disrupt my corner of the industry in the next five

to 10 years?

• What systems do we need to create so that data on how customers use our products feeds back into new design and improves manufacturing?

• Where is the value of digitalization for my company?

• In what technology should my company invest?

• If customers, suppliers and manufacturing are connected, how do we protect data from cyber threats? How do we protect our trade secrets?

• In what skills do we need to train our existing employees?

• What talents should we be looking for in the future?

• What happens if we do nothing?

Industry 4.0, like previous industrial revolutions, is not one-size-fits-all for any industry. However, one thing seems certain: As technology advances, consumers are demanding that change be faster than seems humanly possible. Artificial intelligence in every part of the marketing, sales and manufacturing process is becoming a fact of life as countries race to automate manufacturing. Automation levels the competitive field for products that are labor intensive, especially in countries with growing environmental and employee safety concerns.

Connie Huffa is a textile engineer and co-founder of Fabdesigns Inc. in Malibu, Calif. The company tag line is: “We liked to knit before it was cool.”

Pros

- Small makers can compete effectively, leveraging online marketing and selling platforms, and using WYSIWYG machine builder software.

- More transparency of supply chain and flow of materials, tracking materials, processes, products

and performance in real time. - Automation minimizes defects from human error; optimization of operations to cut costs and improve efficiency.

Cons

- Designs need to fit WYSIWYG parameters.

- Digitalizing opens vulnerabilities to unauthorized access.

- Companies may lose control of data and trade secrets as information is exchanged.

TEXTILES.ORG

TEXTILES.ORG