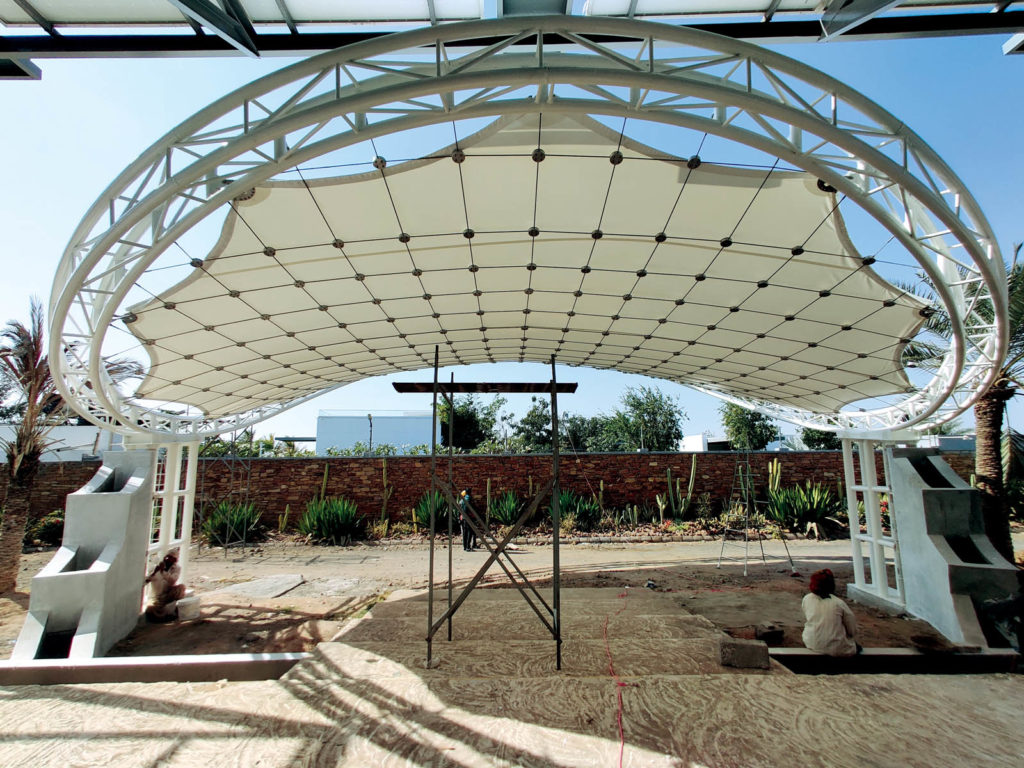

When a client requested a cover for the entry of a workshop/studio, Schafbock Design Workshop of Gujarat, India, took on several challenges, according to Schafbock’s Shehzad Irani. These included the timeline, which was just 45 days from concept design to installation, and the site, a fully functioning hand-printed garment design workshop in a residential area. In addition, the team was challenged with new design processes for the form-find as well as design-engineering and manufacturing of the structure.

With no workers skilled in pre-stressing cable nets, installing or accurately measuring such a complex 3D structure, the responsibility fell on engineer Vipul Mehta and Irani to provide the system detailing, engineering support and project management to be able to realize the structure. This was achieved by ensuring accuracy of the finished structure by continuous monitoring, creating new protocols, methods of measurement, and special customized tools and tackles to do the same using whatever off-the-shelf resources were available. “Once systems were in place it was just a bit more tedious than conventional fabric structures of this scale, but doable,” Irani says.

Established in 2002, Schafbock Design Workshop designs and manufactures tensile structures including car parks, gazebos, tensile roof canopies, portable warehouses and tensioned facades. “This project cracks open the possibility of using cable-supported membrane and roofing systems for large unsupported places with a fraction of the cost and labor engagement for us,” Irani says. “Our team was able to create this structure in record time, and work on different protocols and design-engineering tools to prove and detail such a structure. It is merely a matter of scaling this up now.”

Location: Ler Village, Bhuj, Gujarat, India

Fabric: Sattler Pro-Tex

Size: 12 meters diameter

Project partners: Vipul Mehta and Dipesh Shroff, Schafbock Design Workshop

Photos: Schafbock Design Workshop

TEXTILES.ORG

TEXTILES.ORG