From small startups to global companies, academia and business forge alliances.

Early in 2018, Greensboro, N.C.-based VF Corp. and North Carolina State University (NC State) announced a strategic, multi-year partnership to “support student development at NC State and advance apparel and textiles innovation within VF,” the company says. It will also bring $1 million to the campus in the form of a gift from the VF foundation to the NC State Foundation and give VF Corp. a daily presence in the university’s new research center, the Centennial Campus.

According to Scott Deitz, vice president, public affairs, VF Corp., industry and academic partnerships are “an essential part of doing business today.” However, this relationship comes with a learning curve. “Nobody went to school for this, so it requires a commitment of time, passion and focus,” he says. “Our point of view is that this is a long-term journey. We are making a commitment to NC State, to academia, to the students, and we are going to fulfill our end of the obligation, understanding that it takes time and money.”

The talent pool

Although larger commitments such as VF’s are newsworthy, corporate and academic alliances, generally, aren’t new. HanesBrand Inc., headquartered in Winston Salem, N.C., has had a long relationship with NC State’s College of Textiles and is a good example of how both benefit from the relationship.

According to Jesse Jur, associate professor, Textile Engineering, Chemistry and Science, “They’ve been able to use us as a research arm because we have a research expertise that HanesBrand can leverage that’s very specific to their company.” In return, NC State is one of the company’s primary recruiting locations, engaging the students with special events and in other ways.

Associate professor Sonja Salmon, industrial partnerships manager at NC State’s College of Textiles, left the business world after 20 years to take the university appointment. She, too, sees significant benefits on both sides. For example, the school has about 150 companies participating in continuing education classes for industry professionals. The educational component goes both ways, with students learning from industry mentors as well.

Deitz says continuing education helps people who have been in the business for a long time stay on the leading edge of the industry, whether it’s in business management, navigating a multicultural environment or working with generational characteristics.

Broader participation

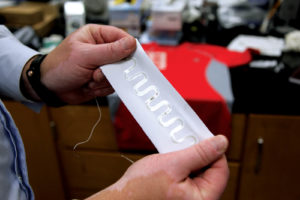

The lines between academic and real-world training are strategically blurred for students at Drexel University in Philadelphia, who do “co-ops” as part of their training. This is a six-month period of working in industry, which is a requirement to earn a degree, according to Genevieve Dion, director of Drexel University’s Center for Functional Fabrics.

“Things are changing in terms of research and innovation,” Dion says. “We’re starting to look at grand challenges, and we’re looking at more than one discipline to solve problems.” She adds that the ability to mix expertise is a great advantage to industry. “It’s an exciting time for making again. We want to have an end-to-end facility where we can iterate and help innovation.”

The Center for Functional Fabrics works with many disciplines and collaborates with designers, engineers, doctors and sociologists. “Different areas of expertise think about different things. Every single field has something to say, something to bring. That’s why it has to be a very agile network,” Dion says. “To create meaningful products, I call it. It’s hard, but it’s really important.”

Drexel, an Advanced Functional Fabrics of America (AFFOA) partner, has also made a significant announcement recently: It now boasts the only Fabric Discovery Center outside of Massachusetts.

Small or global

Both universities are open to a range of partnerships that represent companies from small start-ups to large global corporations, and within that range, their partners have a variety of interests and problems to solve. One start-up may need to build a prototype but doesn’t have the facility to do it; another might not have an invention yet.

Larger companies can use Drexel’s facilities to “spend some time in residence to better understand some aspect of textiles, fabrication technology or something else—some of the basic research that could be done with some of the materials they have, so they can scale up,” says Dion. “We can address some of the basic research aspects, all the way to being more focused on trying to develop a fabric.”

NC State also offers a comprehensive approach. “We can go all the way from extruding a fiber to cutting and sewing a final product. Because we have that infrastructure, companies come to us for service projects,” Salmon says. The entire Centennial Campus at NC State is a collaborative industry and academic environment, with more than 70 companies maintaining offices there.

A small company can benefit from participating with the college in other ways too, such as its consortia, including The Nonwovens Institute, which is funded by industry. “This structure allows even competitor companies to come together and fund some fundamental research,” Salmon says. “They emphasize that this should be pre-competitive research, so all benefit.”

Furthermore, Jur says NC State can be “very fluid” between projects. “We’re able to turn one project on, turn one off, and we’re able to put graduate students on for the length of time necessary,” he says. “It’s difficult for an established company to do this, to look and think like a start-up company might act and think.”

An early start

But NC State doesn’t wait until graduate school, or even undergraduate. Its Summer Textile Exploration Program, or STEP, targets high school students to make them aware of the college’s programs. “Companies have said they want to diversify their workforce, so they need to reach out to pools of people who may not have thought about going to college before and help them apply for scholarships,” Salmon says.

Jur is also co-director of the undergraduate Senior Design Capstone Project, which runs with industry sponsorship. “The students have to go through and understand the IP [intellectual property] space, background literature, establish criteria for what would be project success and create prototypes to offer a solution,” Jur says.

The company that posed the initial problem may or may not use a solution developed in the class, but that’s not necessarily the point. The number one reason companies participate is to understand a new product space. “The company is going to learn something about their existing products, too, and have access to supply chains they haven’t had,” he says.

The close association also offers another close association with students—and the future workforce. This takes on added significance for a large global corporation, such as VF Corp., which operates 170 companies around the world.

“We have more than 40 languages spoken in our company,” Deitz says. “The marketplace is changing; the workplace is changing. We have 65,000 associates around the world. These academic partnerships help us cross these multicultural and multilingual bridges.”

Managing expectations

“It’s not always a straight line in starting something and ending something,” Deitz says, which describes, in short, the challenge of these academic and industry partnerships.

The greatest challenge is figuring out expectations and making sure that both partners can work hand in hand, says Dion. Working in an academic environment can require an adjustment for many businesses, so Salmon agrees that “expectation management is key.”

Part of that is the pace at which work can be accomplished. “There’s more pressure [for a company] to come up with the next product faster. It becomes more and more compressed, which goes opposite to the usual academic timeline,” Salmon says.

“We need to be very clear: this is research,” Jur says. “You have to think about it as a hypothesis, how or why something might be constructed. The project is to see that through to fruition and help the company see that.”

Another challenge, says Jur, is moving beyond the basics and preparing students to be problem solvers. “Most of our classwork is teaching fundamental principles, but the application into practice is something that’s required for them to be successful in the industry … We have to train these students in how to use their fundamental knowledge in solving open-ended problems.”

A link to the future

Dion says she’s seen a lot of products come and go in the last 10 years, but she thinks it’s time to look at why that is. “There’s enough desire to create the functional textiles of the future … to understand all the grand challenges to create not just prototypes, but real products that will sustain use. The best way is to really understand what the market pool is, what the need is, and to work with industry to really deliver,” she says. “We’re on the cusp of being able to do amazing work.”

Janet Preus is senior editor of Advanced Textiles Source, a publication of IFAI.

TEXTILES.ORG

TEXTILES.ORG