The company’s founders could never have imagined the products that Art Display Company is making for its customers today. Back in 1947, when the Maryland sign shop began printing business signage, awnings were cotton canvas, neon signs were cutting-edge technology and everything from painting to sewing was done by hand. Today, the company produces a diverse array of signage for public spaces, institutions and businesses, using innovative textile products, 3-D installations and LED lighting. Textile projects are still finished by hand, though. “Grommets in banners and textile signage are placed by hand and hems are sewn in-house,” says Rich Danoy, vice president of sales at Art Display. Still, handwork is rapidly becoming old-school. Modern printing processes and signage design have dramatically changed the business of fabric graphics.

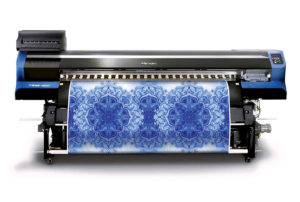

Digital printing technologies and fabric innovations have opened up new possibilities for textile businesses. Chief among those changes is the rise of digital single and multi-pass scanning textile printing equipment, which makes customization, short lead times and high-quality imagery possible for every type of manufacturer, and every type of customer.

Printing transformations

Mark Hanley, president of I.T. Strategies, a Hanover, Mass.-based consulting company that specializes in digital printing, says textile printing is transforming what can be printed, how it will look and who can offer printed textile products. “Single-pass textile printers are stealing away market share from screen printing because they are bigger and faster. If you have a digital printer, you don’t have to stop a machine between jobs; you can queue up 50 jobs in a row and just keep on going, and get to market faster,” he says. “Speed is very important, especially in the fast-fashion world.”

Digital printing enables a trendy image to be brought to market quickly on a mass production level, ready to respond to cultural moments and last-minute requests. Home and fashion fabrics markets in particular have responded to this innovation. British designer Debbie McKeegan, CEO of U.K.-based Texintel, says all of her company’s textiles, which range from contract fabrics to upholstery and wallcoverings, are digitally printed at a micro-factory. “As a bespoke brand we only make products to order. Our online store offers a diverse selection of base substrates and hundreds of patterns. Digital textile printing allows us to be more innovative. We don’t hold stocks and as such can offer our clients an infinite selection of designs,” she says.

McKeegan offers specialized services such as matching fabrics to wallpapers, and also offers sewn and embellished products—including drapes, cushions and upholstery—in small or large quantities for interior designers and retailers. “Lots of our clients need unique prints that are designed for a specific space. Utilizing CAD/CAM technology, we can quickly change the colors and scales of our designs to suit the client’s brief.”

For products that are exposed to the elements and have a long lifespan, digital printing helps facilitate durability. Ink technology has evolved, promising colorfast, durable performance, says Danoy, and modern textiles absorb less dye, reducing costs. The fabrics Art Display uses are designed to endure sun and moisture, and permeated fabric products allow airflow and prevent an installation such as a printed protective wrap used on a construction site from becoming “a sail in the wind.”

According to Danoy, Art Display uses a huge direct-print digital printer to create its textile signage in-house, which is making new products possible and improving the appearance of printed materials. However, he also sees the electronic message boards replacing traditional printed signage. “In 2019, that will be the big thing. It’s a huge market. You can upload a new image or message in seconds and change the sign in place.”

That could be a worrisome trend for suppliers of printed textile signage, but keep in mind that there is a sizable price difference between a changeable, printed banner and a fixed electronic sign, and lighting isn’t appropriate for every application. Many customers still prefer the more traditional look of textiles, with a modern spin. Thanks to digital technologies, even small, one-off projects can look amazing.

Visible quality

Because of the highly visible nature of printed textile products like tents, wraps, banners and awnings, customers are increasingly informed about the possibilities, and they expect the same quality they see out in the world—and they can have it. Manufacturers are investing in digital printing equipment or partnering with printing businesses that can deliver the crisp, rich imagery customers want on vinyl, polypropylene and other fabrics. Where once a simple logo or text was presented, now fabric structures can feature complex and detailed printing, such as fashion photo montages or architectural elevations printed on a

fence wrap for a coming building project.

“We are seeing a demand for easy-to-install, easy-to-recycle products that can be quickly hung for temporary events. These printing processes enable sharp images that look great,” says Hanley. It’s also very easy to market these products. “It takes care of itself. People see it and they love it.”

The increasing visibility of digitally printed signage in communities and commercial environments is its own best marketing. These products are becoming expected parts of many experiences—not just business projects, but also community or even family events.

“We do a lot of products for event planners and athletic directors—things like banners, signage, tents and decals for festivals, gyms and sports teams,” says Michelle Lacy, president of Kempke & Lacy Graphics LLC in Champaign, Ill. “People have high expectations now. They want to see that logo everywhere, on everything. We make products that are long-lasting and will be in place a long time, as well as things like banners featuring individual players that look great but won’t be used forever. Digital printing gives us the ability to make very precise images with a lot of detail.”

Kempke & Lacy Graphics is a new company recently formed from the split-up of longtime manufacturer TCT&A Industries. Lacy hasn’t needed to focus on marketing yet because TCT&A’s reputation for service continues with the new company. “Our customers don’t have time to research products and processes. They just need to know that they will be taken care of. We know what they need and can provide it in a timely manner and at a good price.”

Digital printing is a big part of that capability—although Lacy admits that she misses some of the tactile and visual aspects of the older printing processes. But digital processes make it possible for her to deliver products like senior banners, 3-by-5-foot fabric banners printed with a graduating student’s image. “These are very popular, especially if the student is involved in sports. The digital age allows for high-quality digital images to be printed on a textile without loss of image clarity,” she says. “The expectation is that we can create something spectacular, and this process makes that possible.”

Demand and supply

Digital printing has made it possible for companies to reach customers who might not have been able to access printed textiles in the past. “Some reports indicate the global market for fabric/textiles will reach roughly $1.8 billion at the end of 2018 and is expected to double in the next five years,” says Craig Campbell, director of strategic initiatives at the International Sign Association (ISA), based in Alexandria, Va. “For the sign, graphics and visual communications industry, ISA sees this segment as one of the fastest growing segments due to the amount of versatility of the applications available. For those looking to capitalize on this market, we see interior decor such as window and wall coverings or soft signage such as banners and flags as immediate areas of opportunity.”

According to Campbell, ISA predicts especially strong growth in areas where digital printing is still in the early stages of adoption. “There is more and more crossover happening in specialty markets, like interior branded environments and décor,” he says. “There is a very large trend of printers becoming fabricators and fabricators becoming printers. This is good news for the overall health and growth of our industry, as businesses are both capitalizing on new trends and learning new revenue opportunities to make their business even more successful.”

Derick Tracey at Larsens Inc., a Santa Cruz, Calif.-based company that specializes in canopies, awnings, signage and textile products for the auto racing community and other customers, says digital printing technology has facilitated exponential growth and new products. Larsens creates large-scale textile installations, such as mobile canopies, crowd barriers and curtain walls for semi-trailers. “We have been doing digital printing since 1993. Now we have a grand-format EFI™ VUTEk® GS5250 printer that can do images up to 15 feet wide, with no seams,” says Tracey, vice president of the printing division at Larsens. The VUTEk machine can print on colored fabric using a process in which white ink is applied before other hues.

Tracey credits the company’s choice in fabrics with the success of its product line. It’s weather-resistant and meets a variety of safety regulations—critical for projects intended to shelter people. “We started out doing sails for the marine market, and today we use a unique polyurethane-coated polyester fabric that is a modified version of sailcloth. It performs extremely well for products like tents and canopies.”

But, he says, the printer is pretty terrific too. Before digital printing came into wide use, it would take the company’s workers about four days to hand-apply color to a typical 52-inch by 20-foot banner. And with the digital printer? “Three hours,” he says. That time savings enables Larsens and other businesses to focus more on tasks like outreach, design and meeting higher volumes of demand than would ever have been possible before the world went digital.

Amy Goetzman is a freelance writer based in Maplewood, Minn.

TEXTILES.ORG

TEXTILES.ORG